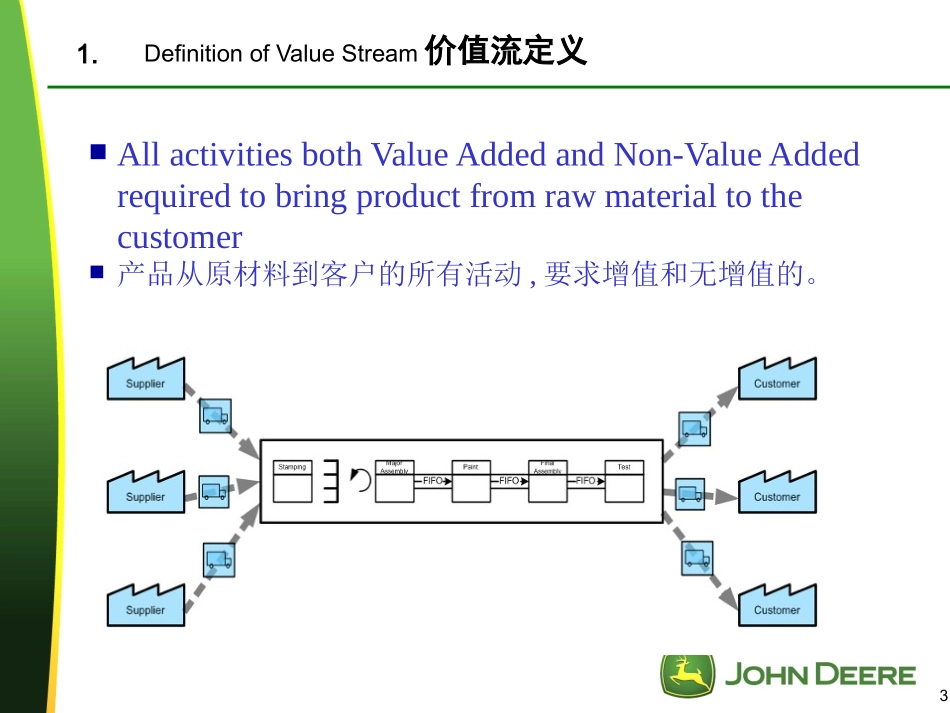

1价值流程图介绍ValueStreamMappingIntroduction2ContentOutline内容大纲1、DefinitionofValueStream价值流程图定义2、Recognizevaluestreammapping初步认识价值流程图3、Thesignificanceofvaluestreammapping绘制价值流程图的意义4、DrawCurrentStateVSM绘制价值流程图5、DrawFutureStatusVSM绘制未来价值流程图3DefinitionofValueStream价值流定义AllactivitiesbothValueAddedandNon-ValueAddedrequiredtobringproductfromrawmaterialtothecustomer产品从原材料到客户的所有活动,要求增值和无增值的。1.4价值流的定义DefinitionofValueStreamDesign/ConfigurationSuppliersContractLogisticCentresLogisticsCustomerSub-systemIntegratorsCustomerRequirementsAValueStreamincludesallelements(bo...