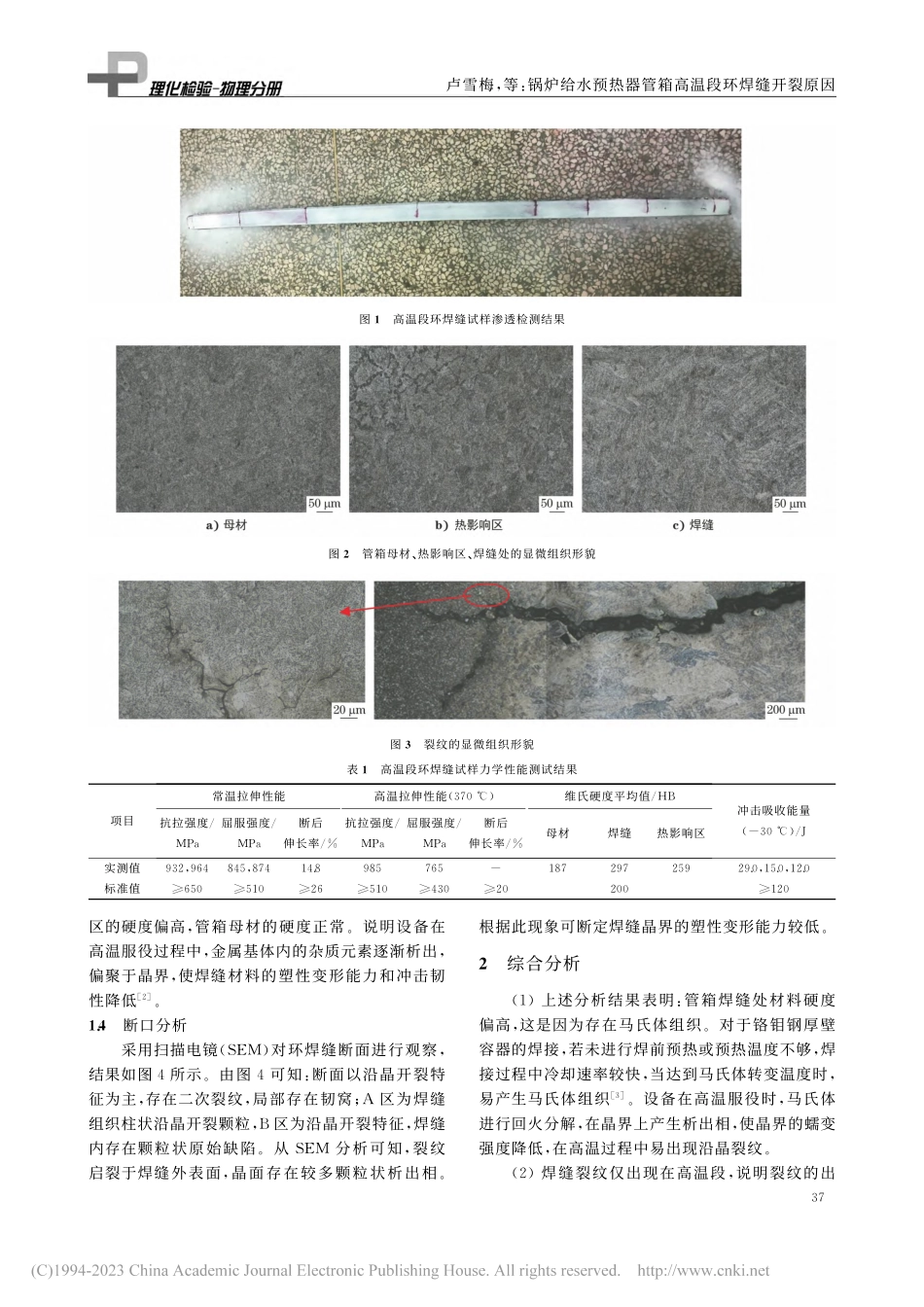

DOI:10.11973/lhjy-wl202302010锅炉给水预热器管箱高温段环焊缝开裂原因卢雪梅,陈梦婷,李燕姣,王亮,宋文明(机械工业上海蓝亚石化设备检测所有限公司,上海201518)摘要:采用渗透检测、金相检验、断口分析和力学性能测试等方法对锅炉给水预热器管箱高温段环焊缝开裂原因进行分析。结果表明:焊后热处理不符合要求,使环焊缝及热影响区形成马氏体;设备在服役过程中,马氏体分解产生析出相,使晶界蠕变能力降低,在高温运行环境下,环焊缝产生再热裂纹并发生沿晶开裂。关键词:锅炉给水预热器;再热裂纹;环焊缝;热处理中图分类号:TG115.5;TQ051.5文献标志码:B文章编号:1001-4012(2023)02-0036-03收稿日期:2022-02-23作者简介:卢雪梅(1982-),女,硕士,高级工程师,主要从事压力容器、压力管道检验以及金属材料的失效分析工作,434673699@qq.comReasonsforcrackingofgirthweldinhightemperaturesectionofboilerfeedwaterpreheatertubeboxLUXuemei,CHENMengting,LIYanjiao,WANGLiang,SONGWenming(MechanicalIndustryShanghaiLanyaPetrochemicalEquipmentTestingInstituteCo.,Ltd.,Shanghai201518,China)Abstract:Penetranttest,metallographicexamination,fractureanalysisandmechanicalpropertiestestwereusedtoanalyzethecausesofgirthweldcrackinginhightemperaturesectionofboilerfeedwaterpreheatertubebox.Theresultsshowthatthepost-weldheattreatmentdidnotmeettherequirements,andmartensitewasformedinthegirthweldandheataffectedzone.Duringtheserviceoftheequipment,ma...