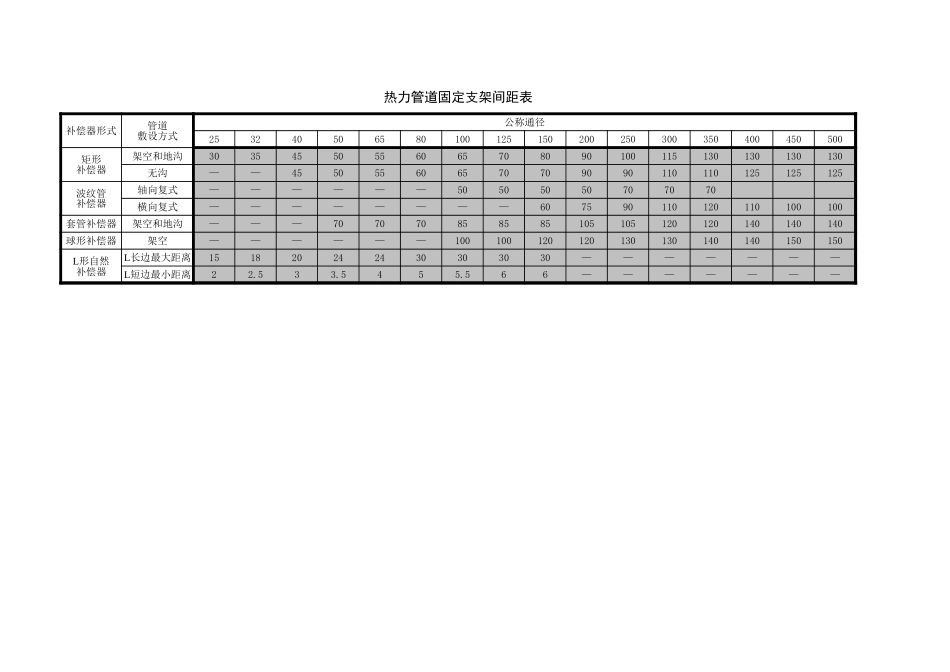

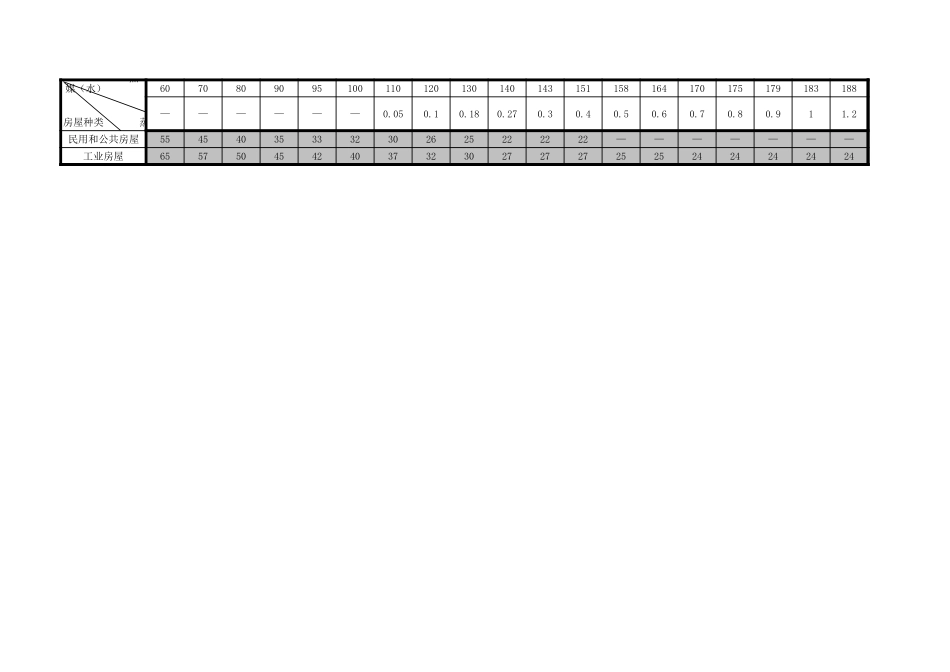

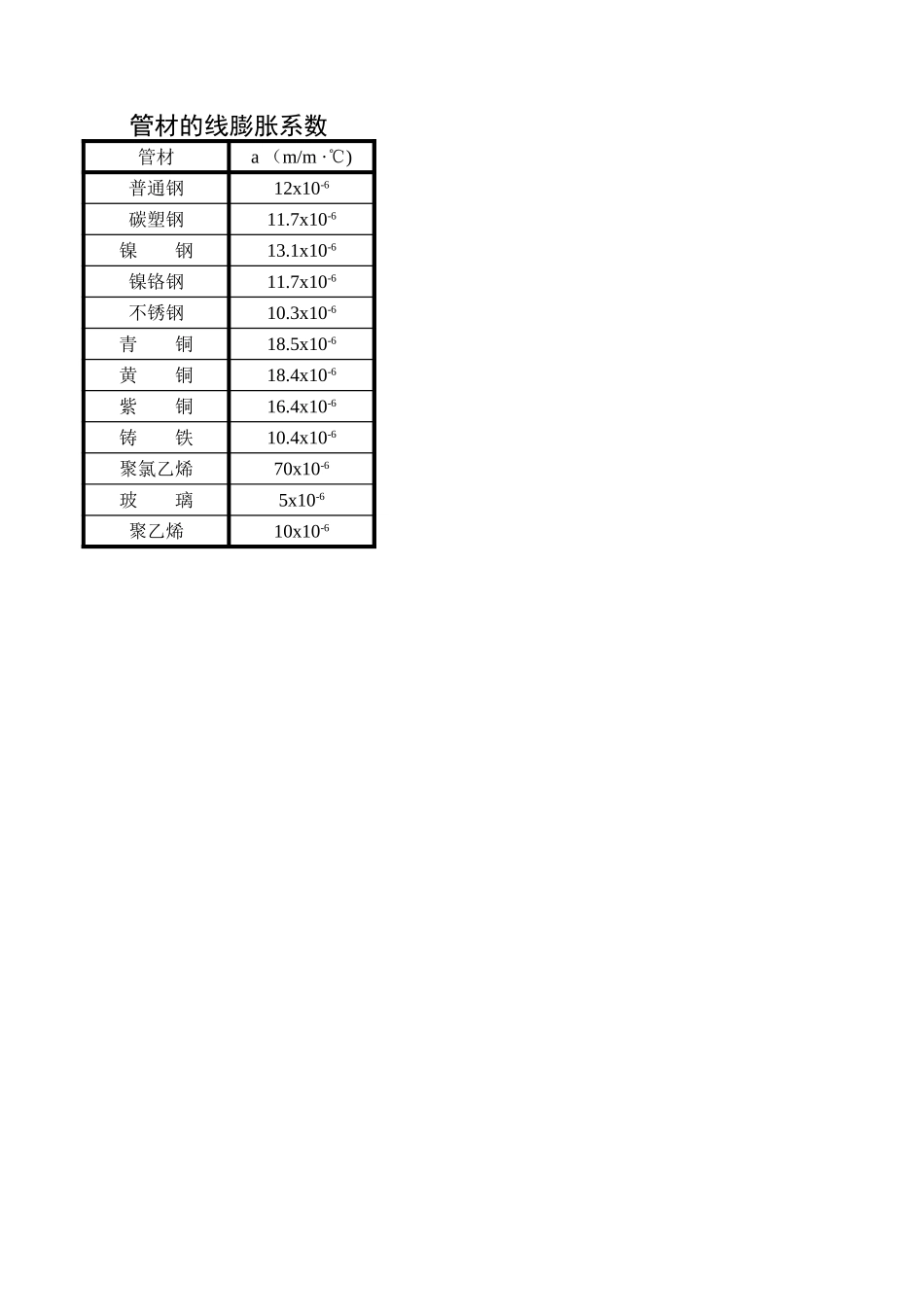

热力管道固定支架间距表补偿器形式公称通径253240506580100125150200250300350400450500架空和地沟30354550556065708090100115130130130130无沟——455055606570709090110110125125125轴向复式——————50505050707070横向复式————————607590110120110100100套管补偿器架空和地沟———707070858585105105120120140140140球形补偿器架空——————100100120120130130140140150150151820242430303030———————22.533.5455.566———————管道敷设方式矩形补偿器波纹管补偿器L形自然补偿器L长边最大距离L短边最小距离6070809095100110120130140143151158164170175179183188——————0.050.10.180.270.30.40.50.60.70.80.911.2民用和公共房屋554540353332302625222222———————工业房屋65575045424037323027272725252424242424热媒(水)房屋种类蒸汽管材的线膨胀系数管材普通钢碳塑钢镍铬钢不锈钢聚氯乙烯聚乙烯a(m/m·℃)12x10-611.7x10-6镍钢13.1x10-611.7x10-610.3x10-6青铜18.5x10-6黄铜18.4x10-6紫铜16.4x10-6铸铁10.4x10-670x10-6玻璃5x10-610x10-61518x30.0111.352025x30.0313.14.192532x30.0779.453238x30.12212.216.474048x3.50.29329.339.565057x3.50.50650.668.316573x3.51.11111149.858089x42.231232.1313.34100108x44.248424.8573.48125133x48.102810.21093.77150159x4.515.6581565.82113.83200219x654.6965469.67383.96250273x7124.312429.616779.96300325x8240.38424038.432451.84350377x9423.38442309.657117.96400426x9615.50461550.483093.04500529x91193.352119335.2161102.52公称通径DN外径x壁厚D1xS(mm)a•E•J•⊿t/107(N•m2/℃)当⊿t为下列值时的a•E•J•⊿t/1(N•m2)⊿t=100℃⊿t=135℃1.5524.816.210.851418.9124.445.458.678.43101.2172.05222359.76464.2658.44849.61255.811620.42426.993131.68477.8810939.219265.8824859.237259.5248067.865579.8884619.295403.12123100.8184969.56238670.4为下列值时的a•E•J•⊿t/107(N•m2)⊿t=155℃⊿t=200℃25322.5275.732.322.5432382.5338.552.794.4140452.54012.573.37.5550573.55019.635.8821.1165733.56634.27.6446.380893.58252.819.4186100108410078.5413.11771251334125122.716.23371501594.5150176.721.96522002194211349.52715596207336.540.22279250273426555133.830537259526.958.451773003254317788.840.354285315778.950....