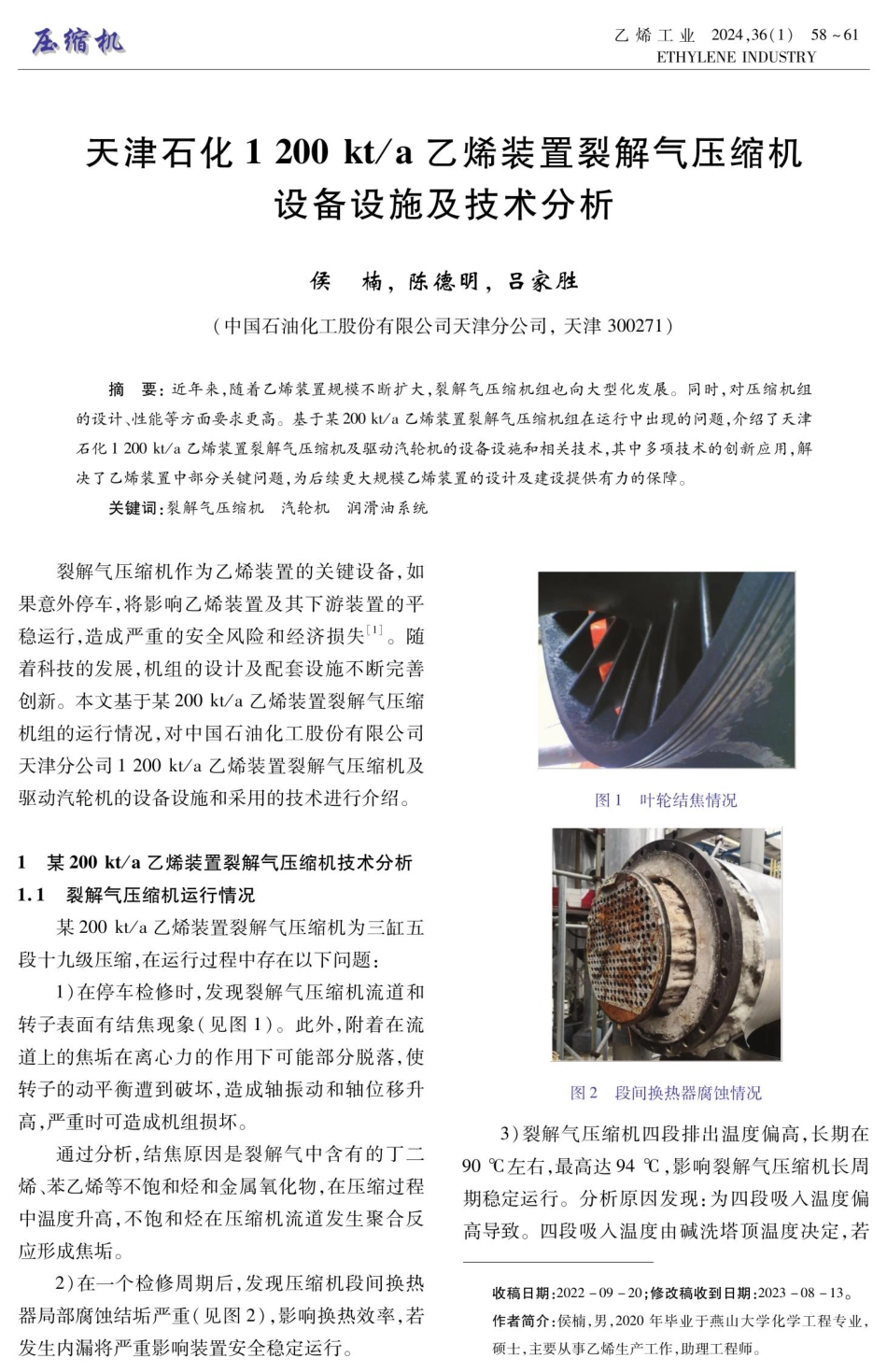

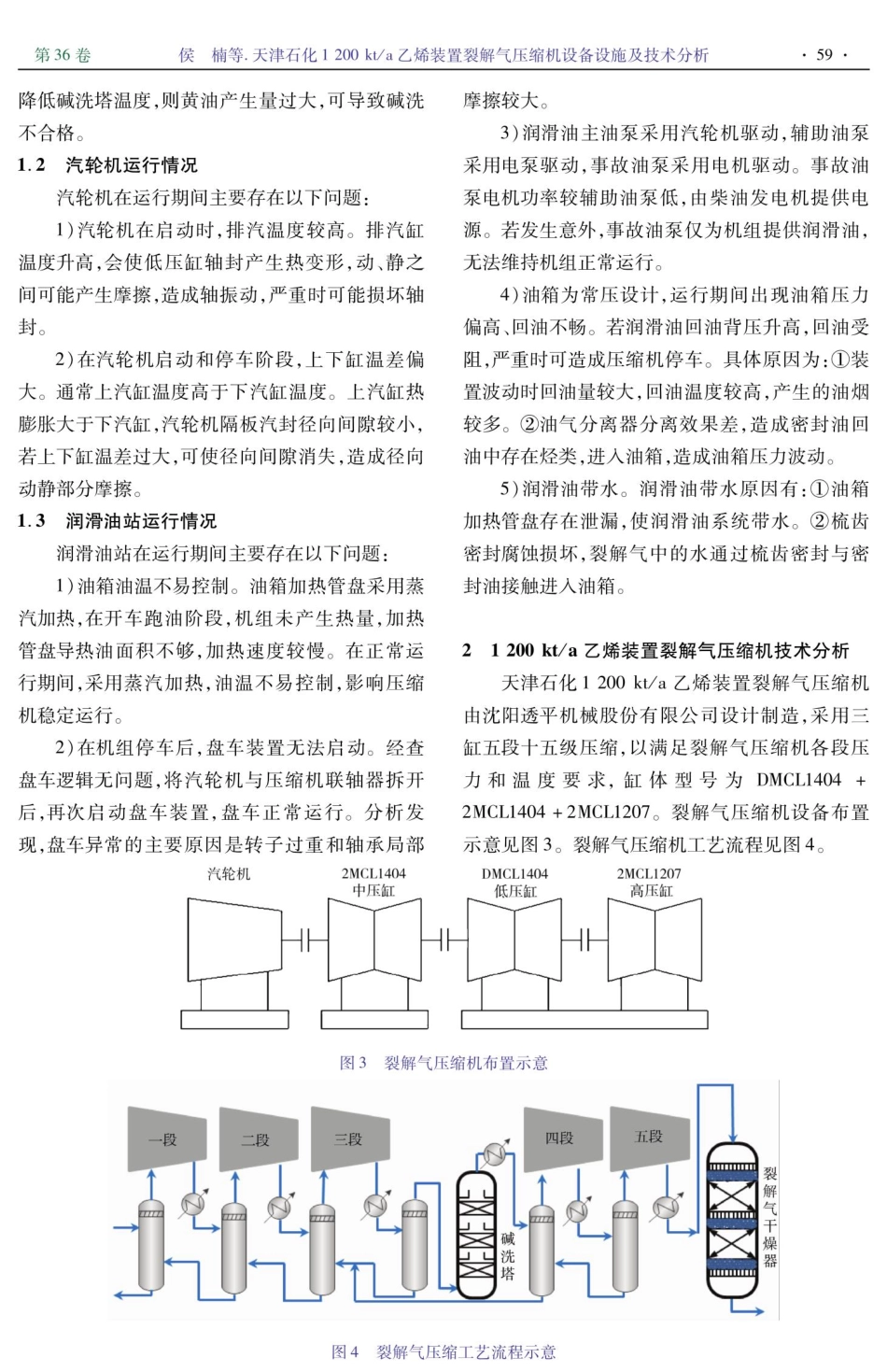

压缩机乙烯工业2024,36(1)58~61ETHYLENEINDUSTRY天津石化1200kt/a乙烯装置裂解气压缩机设备设施及技术分析侯楠,陈德明,吕家胜(中国石油化工股份有限公司天津分公司,天津300271)摘要:近年来,随着乙烯装置规模不断扩大,裂解气压缩机组也向大型化发展。同时,对压缩机组的设计、性能等方面要求更高。基于某200kt/a乙烯装置裂解气压缩机组在运行中出现的问题,介绍了天津石化1200kt/a乙烯装置裂解气压缩机及驱动汽轮机的设备设施和相关技术,其中多项技术的创新应用,解决了乙烯装置中部分关键问题,为后续更大规模乙烯装置的设计及建设提供有力的保障。关键词:裂解气压缩机汽轮机润滑油系统裂解气压缩机作为乙烯装置的关键设备,如果意外停车,将影响乙烯装置及其下游装置的平稳运行,造成严重的安全风险和经济损失["]。随着科技的发展,机组的设计及配套设施不断完善创新。本文基于某200kt/a乙烯装置裂解气压缩机组的运行情况,对中国石油化工股份有限公司天津分公司1200kt/a乙烯装置裂解气压缩机及驱动汽轮机的设备设施和采用的技术进行介绍。1某200kt/a乙烯装置裂解气压缩机技术分析1.1裂解气压缩机运行情况某200kt/a乙烯装置裂解气压缩机为三缸五段十九级压缩,在运行过程中存在以下问题:1)在停车检修时,发现裂解气压缩机流道和转子表面有结焦现象(见图1)。此外,附着在流道上的焦垢在离心力的作用下可能部分脱落,使转子的动平衡遭到破坏,造成轴振动和轴位移升高,严重时可造成机组损坏。通过分析,结焦原因是裂解气中含有的丁二烯、苯乙烯等不饱和烃和金属氧化物,在压缩过程中温度升高,不饱和烃在压缩机流道发生聚合反应形成焦垢。2)在一个检修周期后,发现压缩机段间换热器局部腐蚀结垢严重(见图2),影响换热效率,若发生内漏将严重影响装置安全稳定运行。图1叶轮结焦情况图2段间换热器腐蚀情况3)裂解气压缩机四段排出温度偏高,长期在90℃左右,最高达94℃,影响裂解气压缩机长周期稳定运行。分析原因发现:为四段吸入温度偏高导致。四段吸人温度由碱洗塔顶温度决定,若收稿日期:2022-09-20;修改稿收到日期:2023-08-13。作者简介:侯楠,男,2020年毕业于燕山大学化学工程专业,硕士,主要从事乙烯生产工作,助理工程师。第36卷降低碱洗塔温度,则黄油产生量过大,可导致碱洗不合格。1.2汽轮机运行情况汽轮机在运行期间主要存在以下问题:1)汽轮机在启动时,排汽温度较高。排汽缸温度升高,会使低压缸轴封产生热变形,动、静之...