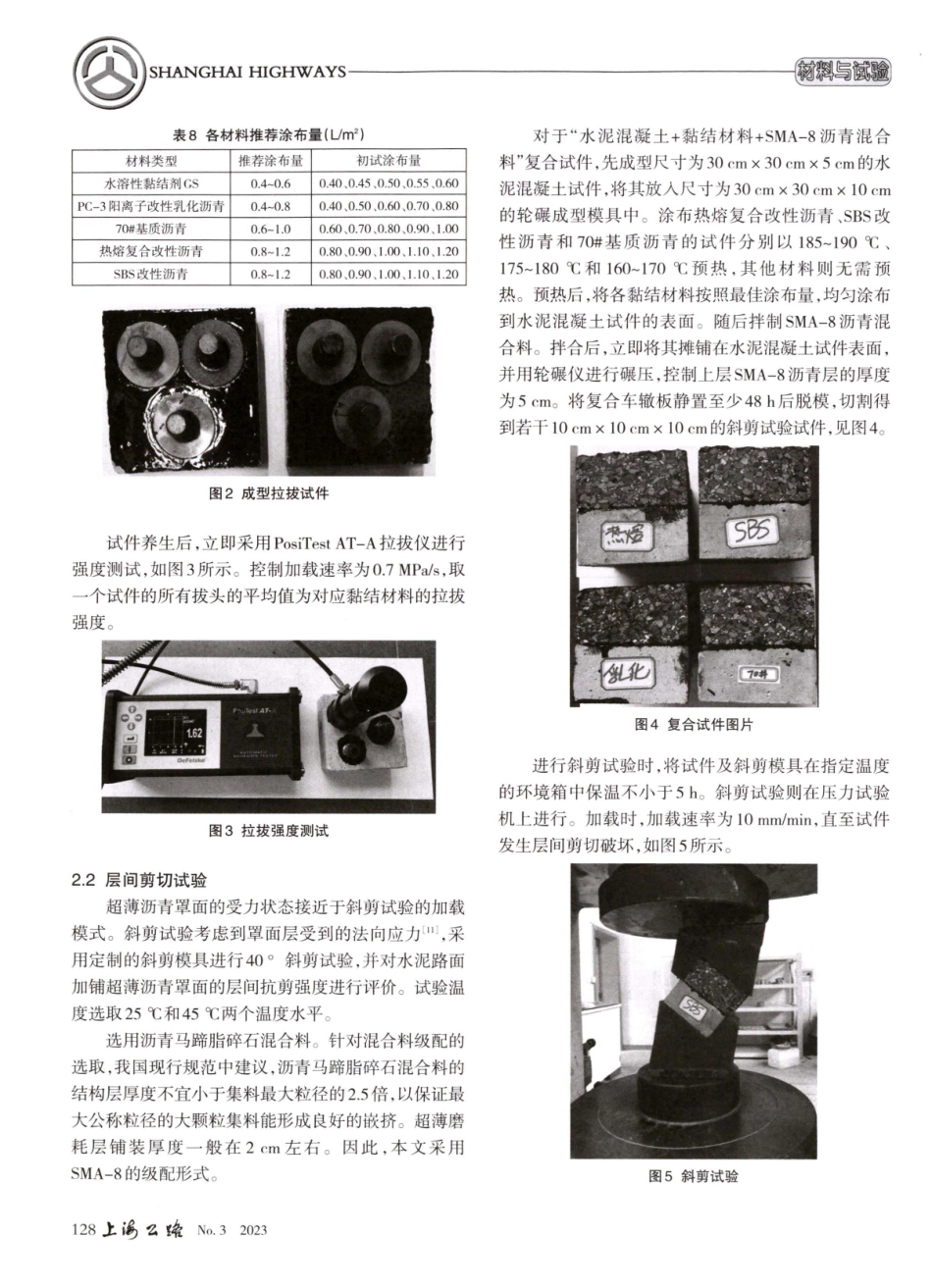

2023No.3126上海么路材料与试验SHANGHAIHIGHWAYS旧水泥路面加铺沥青超薄磨耗层层间黏结性能研究肖梅强,叶奋,胡诗园(1.同济大学道路与交通工程教育部重点实验室,上海201804;2.辽宁省交通规划设计院有限责任公司,辽宁沈阳110166)摘要:旧水泥路面加铺超薄磨耗层的层间黏结性能直接影响到加铺结构的使用寿命。通过成型的复合结构试件,结合层间拉拔试验和斜剪试验,对几种典型防水黏结材料和一种渗透封闭材料的层间黏结性能进行了研究。试验结果表明:各防水黏结材料在最佳涂布量下,拉拔强度排序为热熔复合改性沥青>SBS改性沥青>70#基质沥青>GS>改性乳化沥青。涂布速干型渗透剂F,可提高防水黏结材料的拉拔强度和层间剪切强度,且不改变其最佳涂布量。关键词:旧水泥路面;超薄磨耗层;层间黏结;防水黏结层;渗透封闭层0引言在旧水泥路面的养护中,加铺沥青层是一种常见的方法。其中,超薄磨耗层加铺技术因其施工速度快、原材料消耗少,以及对环境影响小的优势,在近年来得到了更多的关注[1-4]。水泥路面加铺超薄沥青磨耗层的层间黏结性能是直接影响加铺结构使用寿命的关键因素之一[5-6]。由于厚度薄至15~25mm,加铺层在车辆荷载的作用下,会与旧水泥路面间产生较大的法向拉应力和水平向剪应力,使其出现脱层和层间滑移的趋势。因此,对层间黏结材料的拉拔强度和抗剪切强度提出了更高的要求[7]。目前,针对旧水泥路面加铺沥青超薄磨耗层层间黏结性能的研究尚有空白。在水泥路面加铺沥青层之前,需洒布一层防水黏结层材料,用于加铺结构与旧水泥路面板块之间的黏结。在某些工艺中,会在洒布黏层材料前,往旧水泥路面上涂布一种速干型渗透剂,作为渗透封闭层。通过对旧水泥路面板块的有效渗透,提高防水黏结层与旧水泥混凝土板块之间的黏结强度[8],如图1所示。,防水粘结层渗透封闭层旧水泥路面板块图1渗透封闭层示意图本文以几种代表性的热沥青、乳化沥青和水溶性黏结剂GS作为防水黏结层材料的研究对象,以某种速干型渗透剂材料F作为渗透封闭层材料的研究对象,通过拉拔试验和不同温度下的斜剪试验,来评价不同材料组合形式下的黏结性能,为旧水泥路面加铺沥青超薄磨耗层提供最优的层间黏结方案1原材料及性能本文选用的防水黏结材料为70#基质沥青、SBS改性沥青、热熔复合改性沥青、水溶性黏结剂GS和PC-3阳离子改性乳化沥青,相应的技术指标分别如表1~5所示。本文选用的速干型渗透剂材料F技术指标见表6。表170#基质沥青技术指标项目单位指标试验方...