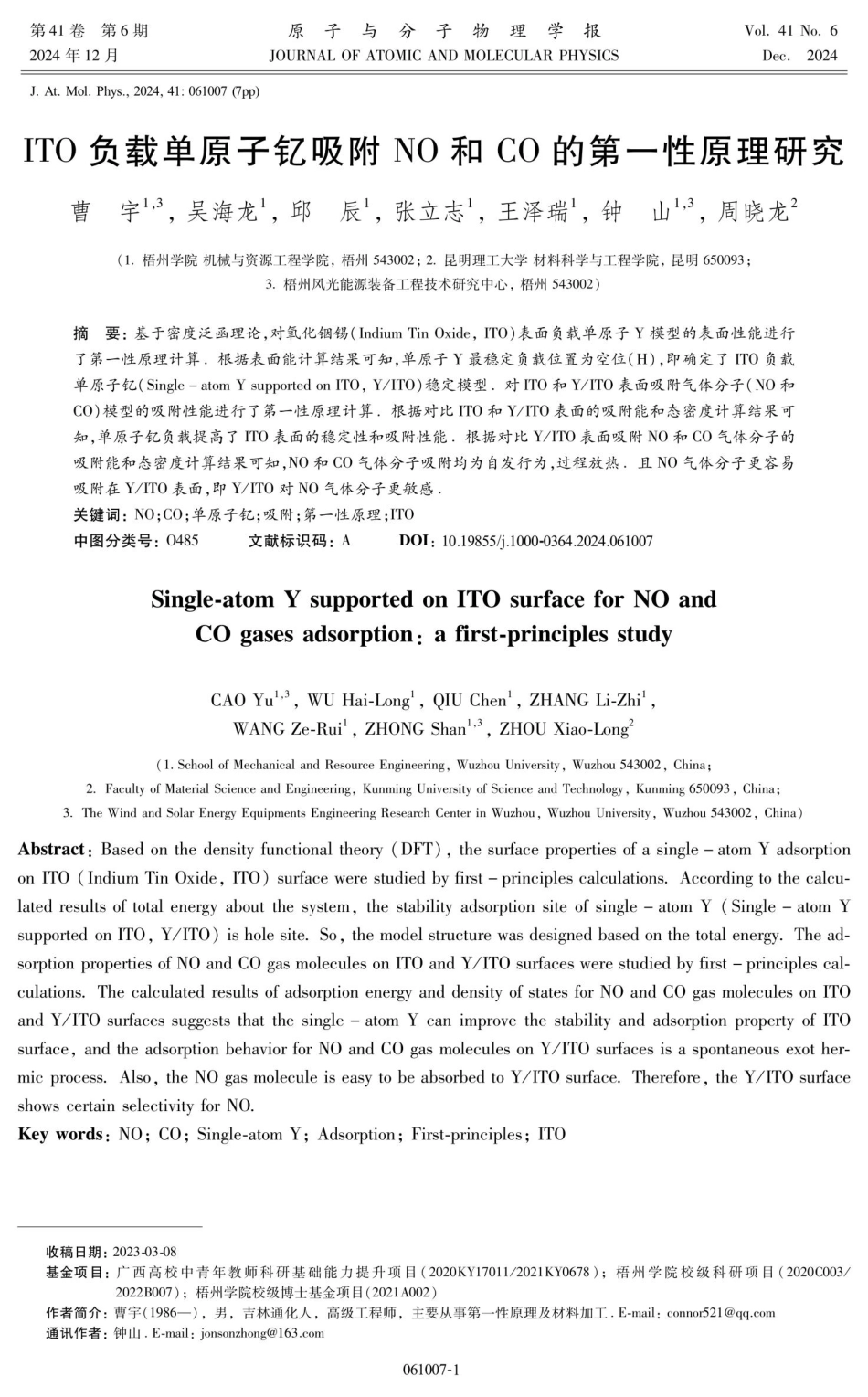

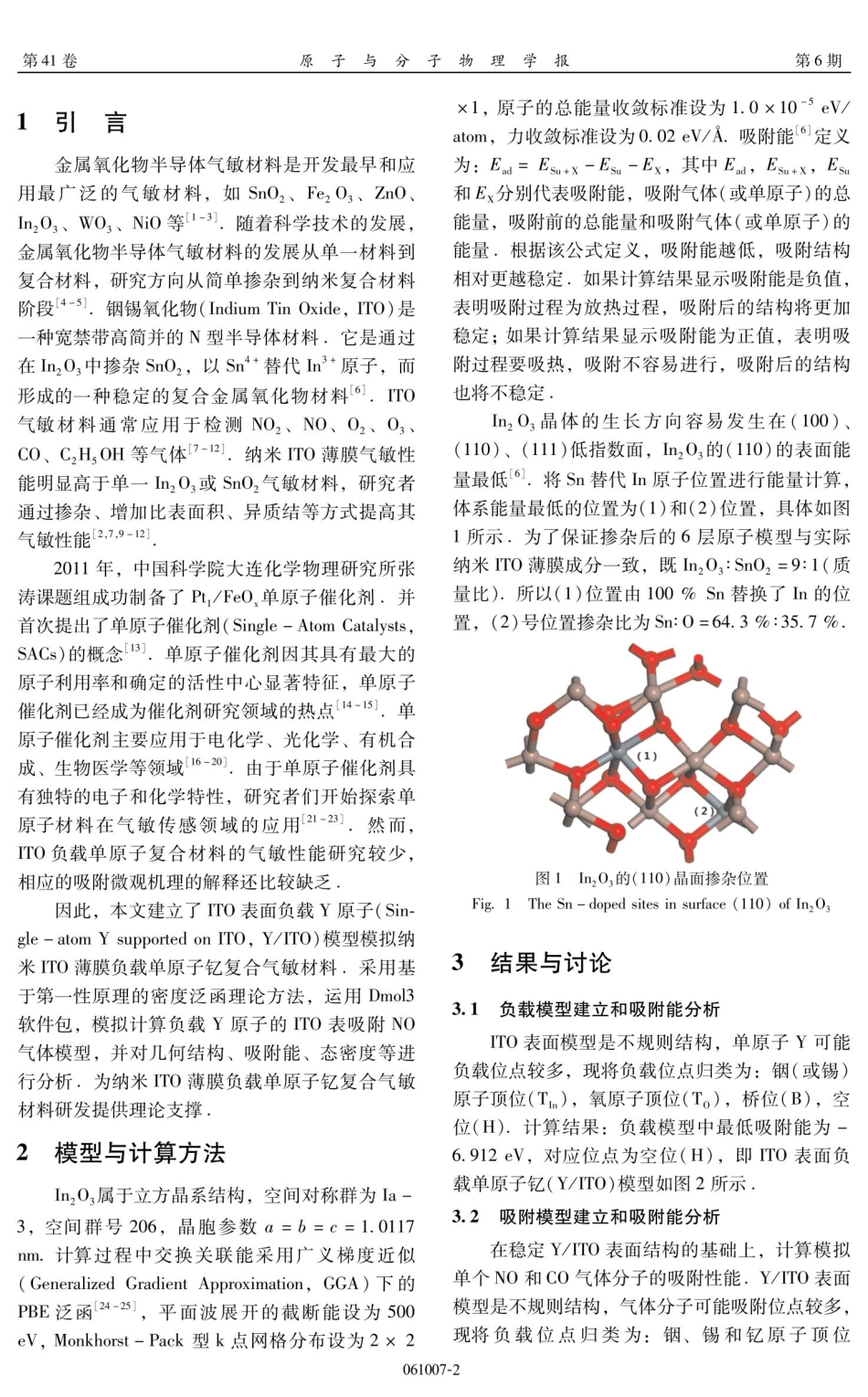

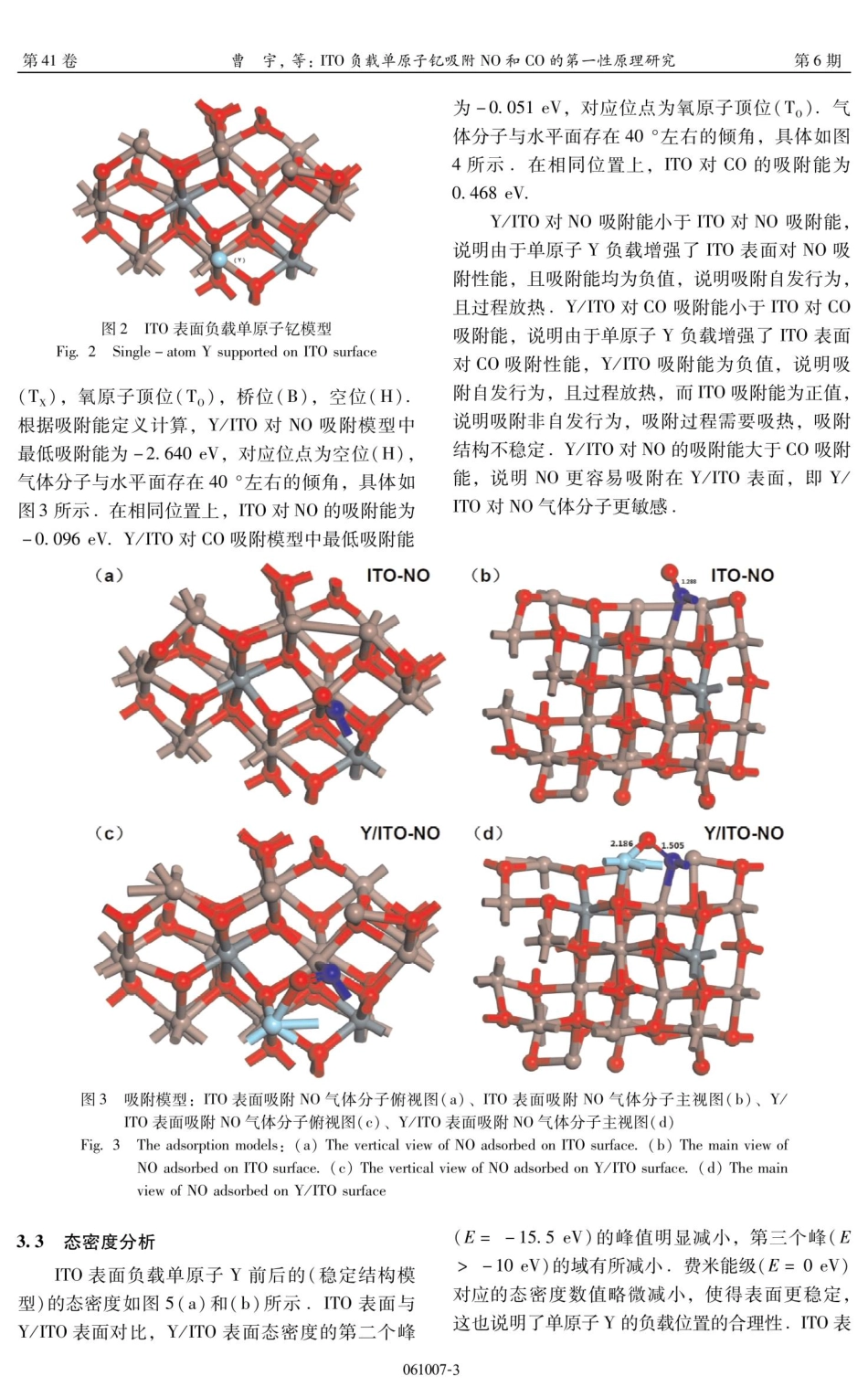

第41卷第6期2024年12月J.At.Mol.Phys.,2024,41:061007(7pp)ITO负载单原子钇吸附NO和CO的第一性原理研究原子与分子物理学报JOURNALOFATOMICANDMOLECULARPHYSICSVol.41No.6Dec.2024曹宇13,吴海龙,邱辰",张立志",王泽瑞",钟(1.梧州学院机械与资源工程学院,梧州543002;2.昆明理工大学材料科学与工程学院,昆明650093;3.梧州风光能源装备工程技术研究中心,梧州543002)摘要:基于密度泛函理论,对氧化铟锡(IndiumTinOxide,ITO)表面负载单原子Y模型的表面性能进行了第一性原理计算:根据表面能计算结果可知,单原子Y最稳定负载位置为空位(H),即确定了ITO负载单原子(Single-atomYsupportedonITO,Y/ITO)稳定模型.对ITO和Y/ITO表面吸附气体分子(NO和CO)模型的吸附性能进行了第一性原理计算:根据对比ITO和Y/ITO表面的吸附能和态密度计算结果可知,单原子钇负载提高了ITO表面的稳定性和吸附性能.根据对比Y/ITO表面吸附NO和CO气体分子的吸附能和态密度计算结果可知,NO和CO气体分子吸附均为自发行为,过程放热:且NO气体分子更容易吸附在Y/ITO表面,即Y/ITO对NO气体分子更敏感.关键词:NO;CO;单原子钇;吸附;第一性原理;ITO中图分类号:0485Single-atomYsupportedonITOsurfaceforNOandCOgasesadsorption:afirst-principlesstudy钟山13,周晓龙2文献标识码:AD0I:10.19855/j.1000-0364.2024.061007CAOYu'",WUHai-Long",QIUChen',ZHANGLi-Zhi',WANGZe-Rui',ZHONGShan'-,ZHOUXiao-Long(1.SchoolofMechanicalandResourceEngineering,WuzhouUniversity,Wuzhou543002,China;2.FacultyofMaterialScienceandEngineering,KunmingUniversityofScienceandTechnology,Kunming650093,China;3.TheWindandSolarEnergyEquipmentsEngineeringResearchCenterinWuzhou,WuzhouUniversity,Wuzhou543002,China)Abstract:Basedonthedensityfunctionaltheory(DFT),thesurfacepropertiesofasingle-atomYadsorptiononITO(IndiumTinOxide,ITO)surfacewerestudiedbyfirst-principlescalculations.Accordingtothecalcu-latedresultsoftotalenergyaboutthesystem,thestabilityadsorptionsiteofsingle-atomY(Single-atomYsupportedonITO,Y/ITO)isholesite.So,themodelstructurewasdesignedbasedonthetotalenergy.Thead-sorptionpropertiesofNOandCOgasmoleculesonITOandY/ITOsurfaceswerestudiedbyfirst-principlescal-culations.Thecalculatedresultsofadsorptionenergy...