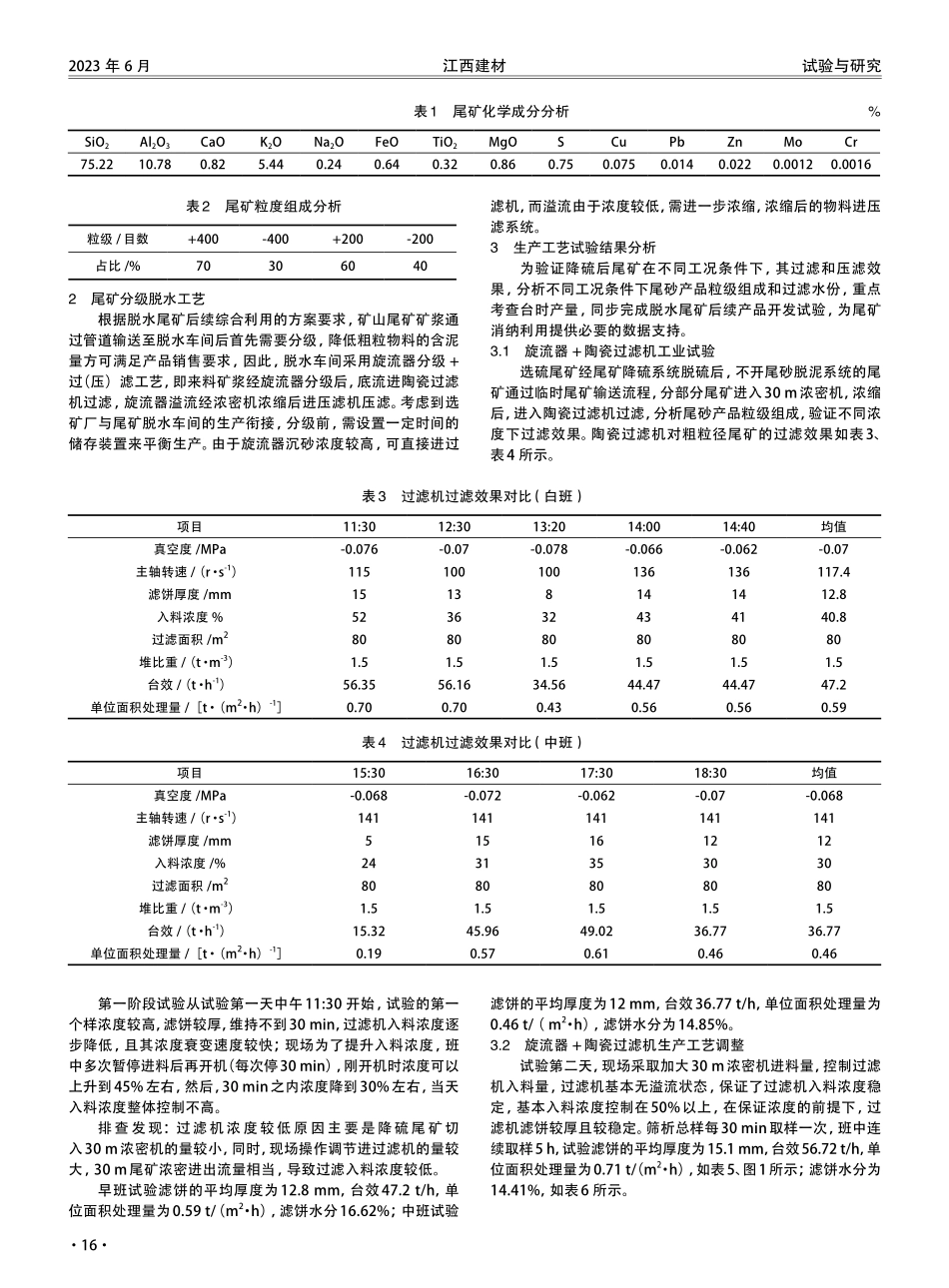

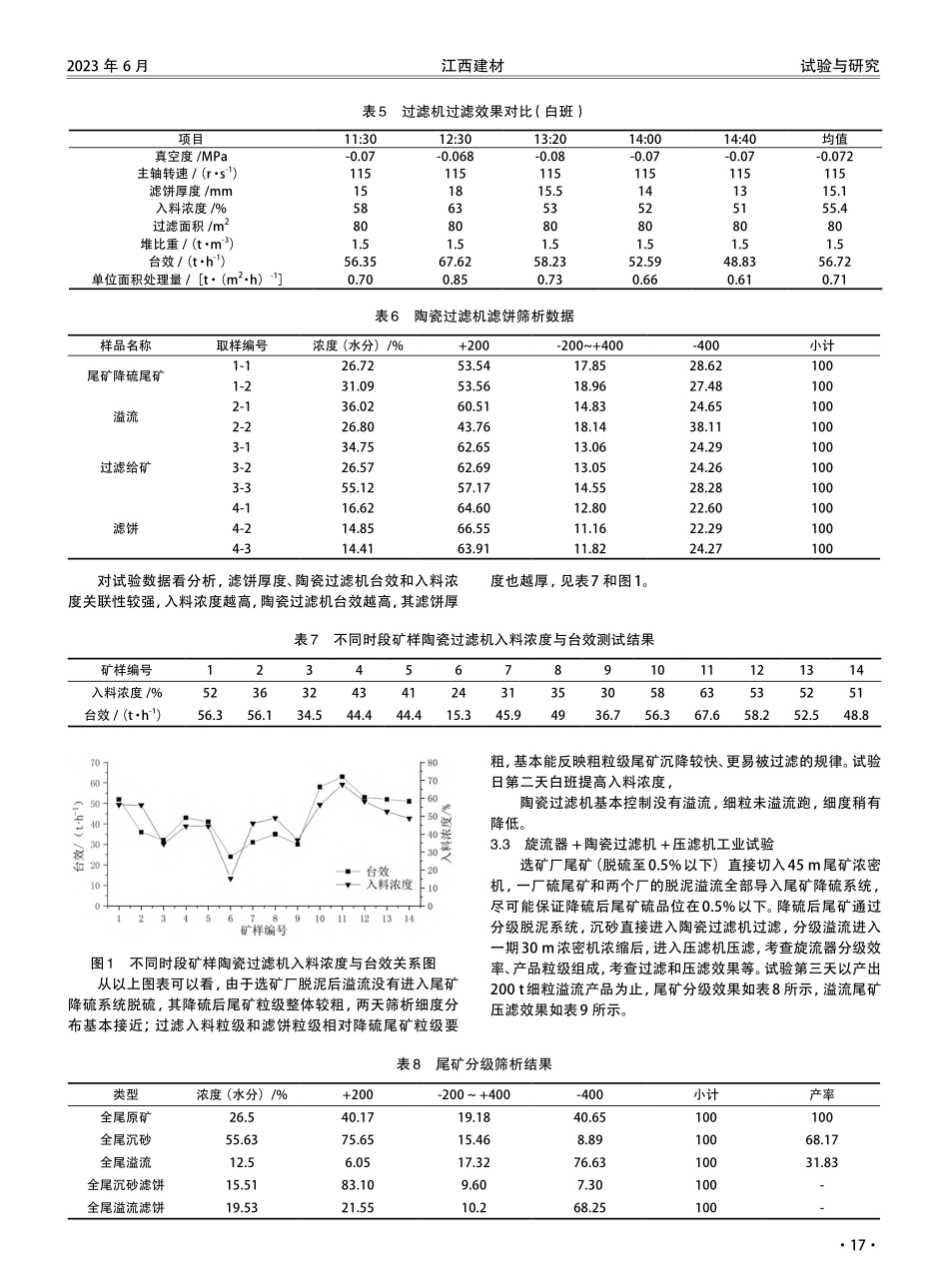

江西建材试验与研究·15·2023年6月江西某矿山尾矿分级脱水生产工艺研究胡翔1,石齐2*1.江西瑞金万年青水泥有限责任公司,江西赣州341000;2.江西省建材科研设计院有限公司,江西南昌330001摘要:文中以江西某矿山脱硫尾矿为研究对象,通过对其分级脱水生产工艺进行试验研究,结果表明,若采用“旋流分级器+陶瓷过滤机”的脱水生产工艺,入料浓度控制在50%以上,过滤机滤饼较厚且较稳定,平均厚度为15.1mm,陶瓷过滤机台效为56.72t/h,单位面积处理量为0.71t/(m2·h),滤饼水分14.41%,但细粉料颗粒含量较多。若采用“旋流分级器+陶瓷过滤机+压滤机”的脱水生产工艺,沉砂尾矿+200目占80%左右,滤饼较厚,但滤饼厚薄不均匀,平均含水率约18%;而溢流尾矿平均压滤时间大约13min/板,每板压矿量平均为2.44t,滤饼水分整体较高,对整体分级脱水工艺环节精细化控制要求较高。关键词:尾矿;分级脱水;过滤;工艺中图分类号:TD862文献标识码:B文章编号:1006-2890(2023)06-0015-04ResearchontheProductionProcessofTailingsGradedDehydrationProcessinaCertainMineinJiangxiHuXiang1,ShiQi2*1.JiangxiRuijinWannianQingCementCo.Ltd.,Ganzhou,Jiangxi341000;2.JiangxiBuildingMaterialsRearchAndInstrituteCo.Ltd.,Nanchang,Jiangxi330001Abstract:TakingaresearchtargetofaminesinJiangxiasaresearchobject,theproductiontestofitsclassificationdehydrationproductionprocessisconducted.Theresultsshowthatifthedehydrationproductionprocessofthe"spin-strickenclassifier+ceramicfilter"isusedAbove,thefilterfiltercakeisthickerandstable,withaveragethicknessof15.1mm,ceramicfiltertableefficiencyof56.72t/h,andtheunitareaprocessingvolumeis0.71t//(m2·h),andthefiltercakewateris14.41%,butfinepowdermaterials,butfinepowdermaterialsTherearemoreparticles.Ifthedehydrationproductionprocessofthe"spingrades+ceramicfilter+filtermachine",thesandtailmines+200metersaccountforabout80%.;Theaveragefiltrationtimeoftheoverflowtailmineisabout13min/board,andtheamountofcompressionperplateisanaverageof2.44t.Theoverallwaterofthefiltercakeishigh,andtherefinedcontrolrequirementsfortheoverallclassificationdehydrationprocessarehigh.Keywords:Tailings;Gradeddehydration;Filter;Process作者简介:胡翔(1989-),男...