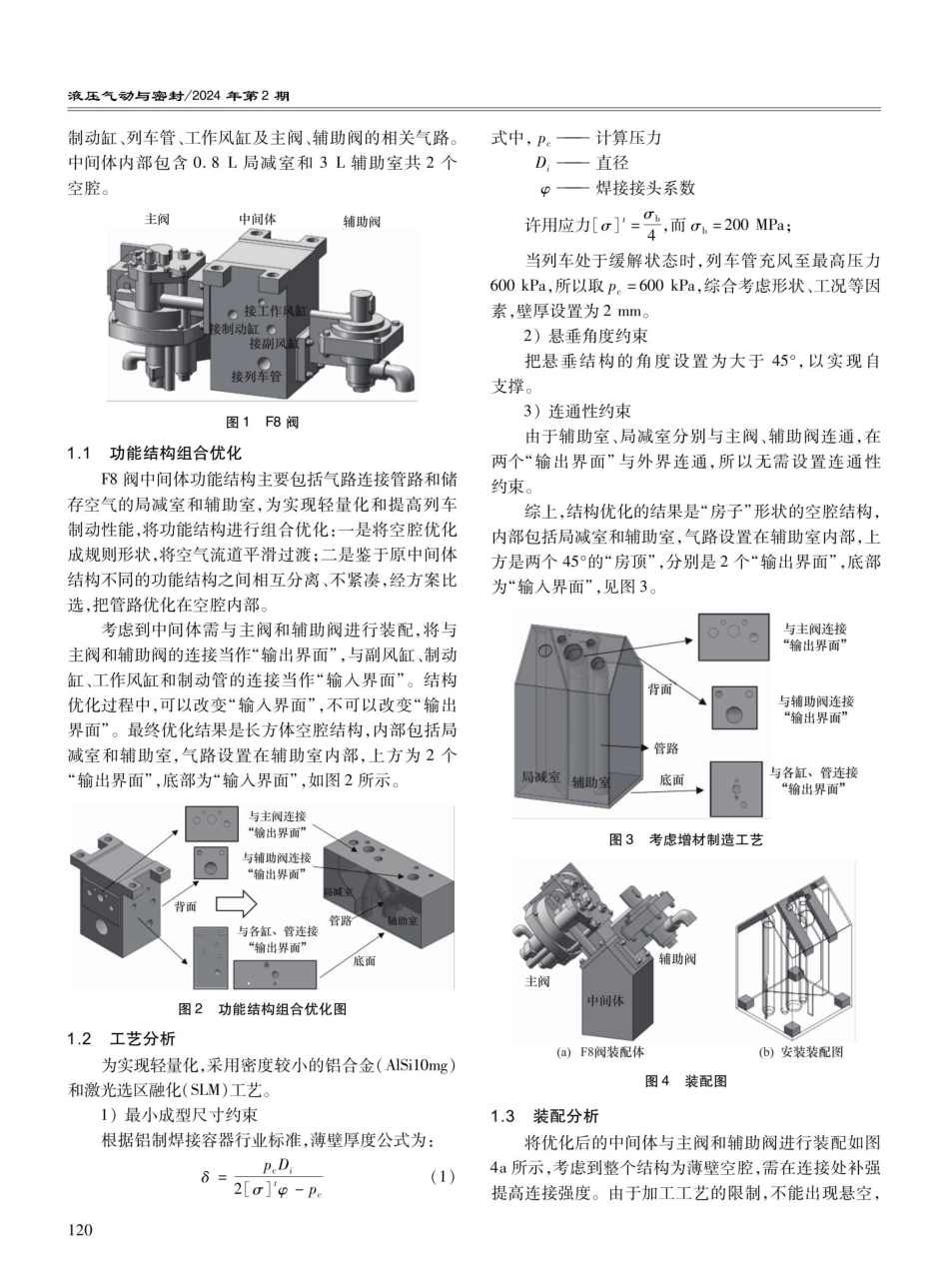

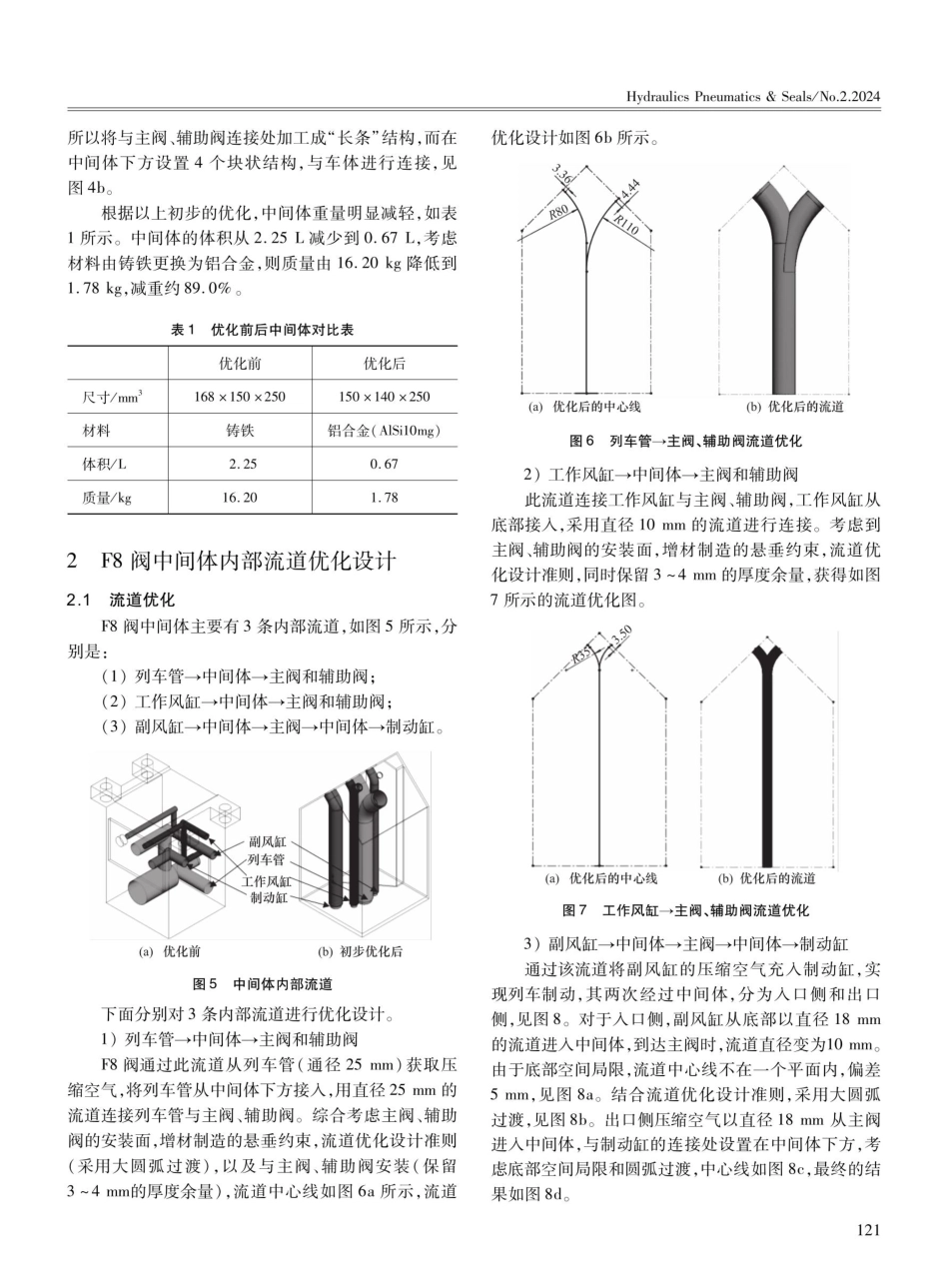

HydraulicsPneumatics&Seals/No.2.2024doi:10.3969/j.issn.1008-0813.2024.02.022基于增材制造技术的F8型分配阀结构优化设计王拥军,吴修彬(莱芜职业技术学院,山东济南271100)摘要:基于增材制造技术思路构建了F8型空气分配阀结构模型,利用Fluent软件对F8型空气分配阀内部流道进行仿真优化,利用ANSYS进行有限元仿真进行残余应力和变形量分析,采用试验手段对仿真结果进行验证。结果表明:基于增材制造技术制造的F8型空气分配阀可以实现部件轻量化和提高列车制动性能,中间体相比于原设计可减重89.0%,最小级位常用制动和大级位制动时制动缸充风速率可分别提升13.5%和21.6%,部件残余应力和变形量可满足使用要求。提供了基于增材制造技术的F8型分配阀结构优化设计的新思路,也对其他结构复杂产品的智能制造提供了重要参考。关键词:增材制造技术;F8型空气分配阀;建模;ANSYS;优化设计中图分类号:TH137Abstract:Inthispaper,thestructuralmodelofF8airdistributorvalveisbuiltbasedontheideaofadditivemanufacturingtechnology,andthentheinternalflowchannelofF8airdistributorvalveissimulatedandoptimizedbyFluentsoftware,andtheresidualstressanddeformationareanalyzedbyfiniteelementsimulationusingANSYS.Finally,thesimulationresultsareverifiedbyexperimentalmeans.TheresultsshowthattheF8airdistributionvalvemanufacturedonthebasisofadditivemanufacturingtechnologycanrealizetheweightreductionofcomponentsandimprovethebrakingperformanceofthetrain.Comparedwiththeoriginaldesign,theweightoftheintermediatecanbereducedby89.0%.Theairchargingrateofthebrakecylindercanbeincreasedby13.5%and21.6%respectivelywhentheminimumlevelservicebrakeandthelargelevelbrakeareapplied.Theresidualstressanddeformationofthecomponentscanmeettheuserequirements.ThispaperprovidesanewideaforstructuraloptimizationdesignofF8distributorvalvebasedonadditivemanufacturingtechnology,andalsoprovidesanimportantreferenceforintelligentmanufacturingofotherproductswithcomplexstructure.Keywords:additivemanufacturingtechnology;F8airdistributorvalve;modeling;ANSYS;optimizeddesign0引言制动系统是列车安全运行的保障,主要分为直通式制动系统和自动式制动系统,其中自动式制动系统具有可以实现灵活编组、运用和检...