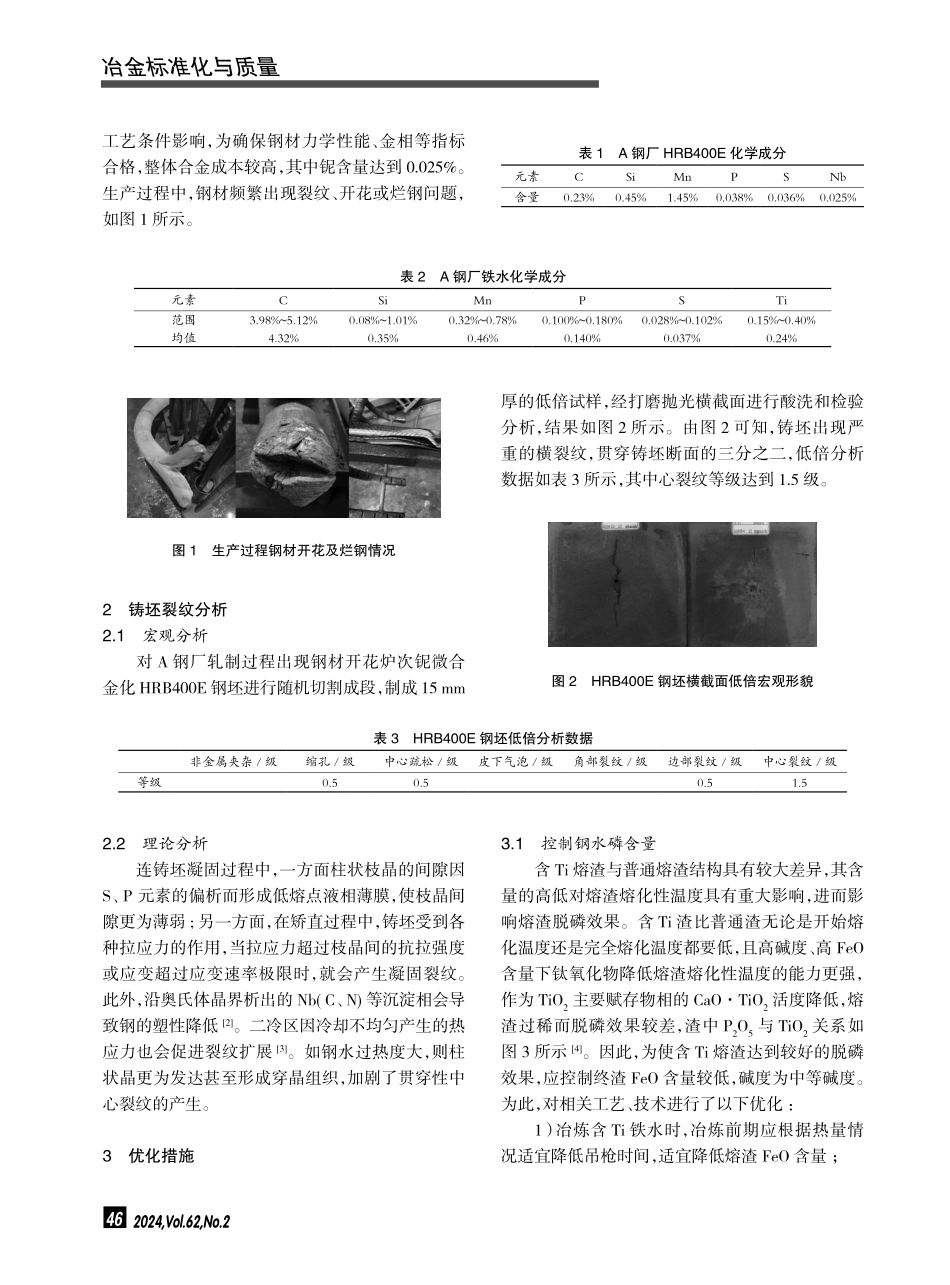

技术应用452024,Vol.62,No.2452024,Vol.62,No.2收稿日期:2023-11-08作者简介:华福波(1992~),男,工程师。E-mail:1527324162@qq.com铌微合金化HRB400E钢铸坯裂纹研究与控制华福波,王劼,周玉杭,魏福龙,谢祥(首钢水城钢铁集团公司贵州六盘水553028)摘要:铌是热轧带肋钢筋常用微合金化元素,具有细化奥氏体晶粒、沉淀硬化作用,且与钒相比价格较低具有较好的性价比。但因其元素特性,在铸坯冷却过程中易形成贯穿性裂纹,轧制时钢材开裂而导致堆钢。本文通过研究铌微合金化铸坯裂纹形成机理,采取优化钢水成分、低过热度浇注、二次冷却工艺优化等措施,有效解决了铸坯裂纹问题,轧制过程因铸坯裂纹导致的万吨堆钢率由1.32支降低至0.04支。关键词:铌微合金化;裂纹;机理;堆钢中图分类号:TF704文献标识码:B文章编号:1003-0514(2024)02-0045-04StudyandpracticeofBOFless-slagsteelmakingtechnologywithhigh-titaniumhotmetalHuaFubo,WangJie,ZhouYuhang,WeiFulong,XieXiang(ShougangShuichengIron&Steel(Group)Co.,Ltd.,Liupanshui553028,China)Abstract:Niobiumisacommonlyusedmicroalloyingelementforhot-rolledridgedsteelbars,whichhastheeffectofrefiningaustenitegrainsandprecipitationhardening.Comparedwithvanadium,niobiumhasalowerpriceandabettercostperformance.However,duetoitselementcharacteristics,itiseasytoformpenetratingcracksinthecoolingprocessofthebillet,andthesteelcrackingduringrollingleadstothepiling-upofsteel.Inthispaper,thecrackformationmechanismofniobiummicroalloyingcastingbilletisstudied,andthecrackproblemofcastingbilletiseffectivelysolvedduetotheresultsofoptimizingthecompositionofmoltensteel,lowsuperheatcasting,secondarycoolingprocessoptimization,etc.Therateof10thousandtonsofpilesteelcausedbythecrackofcastingbilletisreducedfrom1.32to0.Keywords:minorNballoying;crack;mechanism;piling-upofsteel铌和钒的物理特性相近,作为微合金化元素具有沉淀硬化作用,并在一定程度上可细化奥氏体晶粒,改善钢的韧性和抗疲劳性能。且对应原料铌铁供应量充足、价格稳定,与使用钒相比合金成本较低。因此被多家钢厂作为替代钒强化的首选元素。但A钢厂160mm×160mm小方坯连铸机在使用铌铁配铌生产HRB400E钢筋时,连铸坯频繁出现横裂纹,轧制过程钢材开裂导致堆...