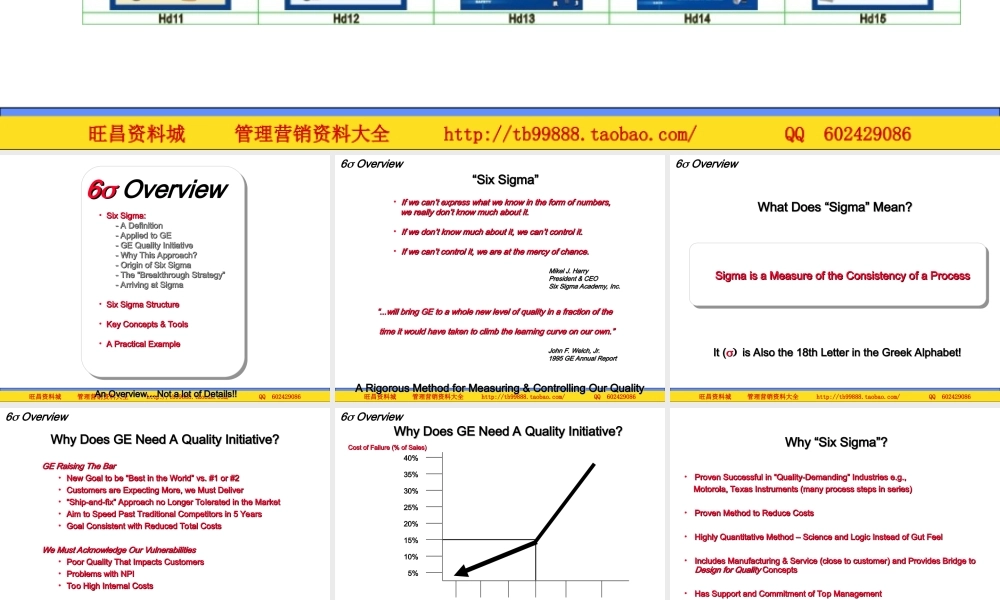

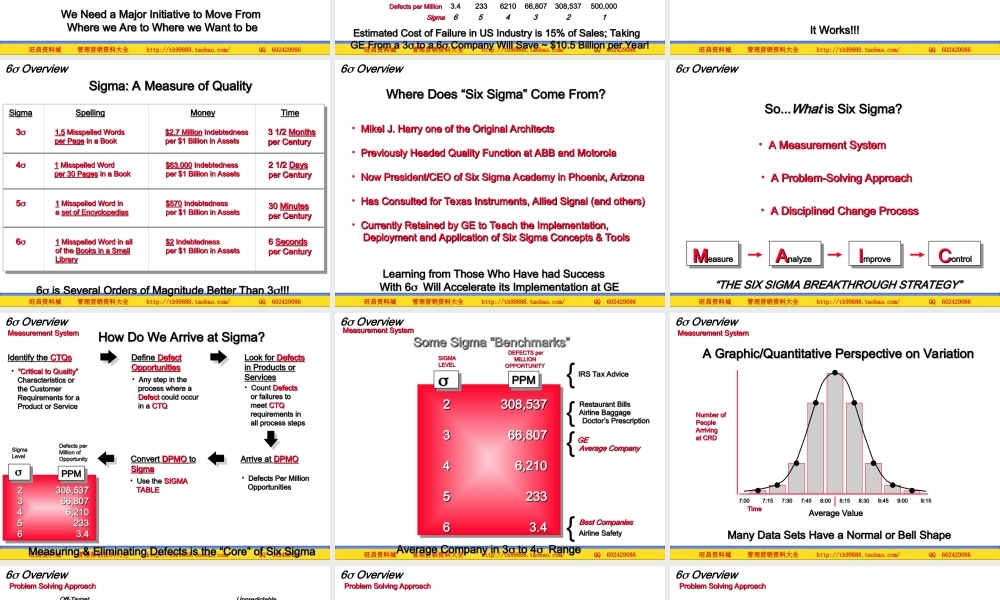

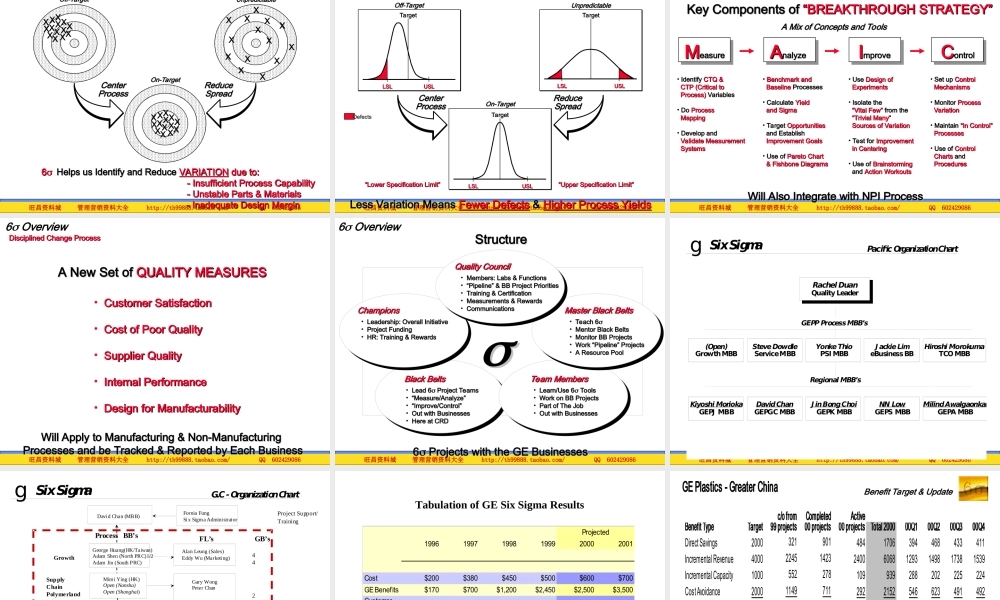

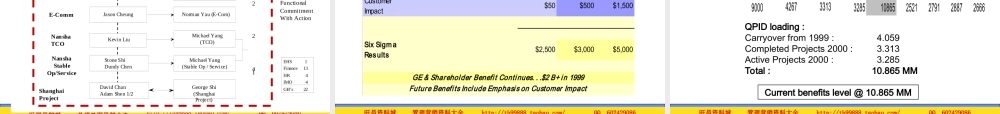

免费注册商,每天三小时推广,每月收入高达3000以上:注册网站:http://goodword.teasm.cn/旺昌资料城管理营销资料大全http://tb99888.taobao.com/QQ602429086免费注册商,每天三小时推广,每月收入高达3000以上:注册网站:http://goodword.teasm.cn/旺昌资料城管理营销资料大全http://tb99888.taobao.com/QQ60242908666Overview•SixSigma:SixSigma:-ADefinition-ADefinition-AppliedtoGE-AppliedtoGE-GEQualityInitiative-GEQualityInitiative-WhyThisApproach?-WhyThisApproach?-OriginofSixSigma-OriginofSixSigma-The“BreakthroughStrategy”-The“BreakthroughStrategy”-ArrivingatSigma-ArrivingatSigma•SixSigmaStructureSixSigmaStructure•KeyConcepts&ToolsKeyConcepts&Tools•APracticalExampleAPracticalExampleAnOverview....NotalotofDetails!!AnOverview....NotalotofDetails!!免费注册商,每天三小时推广,每月收入高达3000以上:注册网站:http://goodword.teasm.cn/旺昌资料城管理营销资料大全http://tb99888.taobao.com/QQ6024290866Overview““SixSigma”SixSigma”•Ifwecan’texpresswhatweknowintheformofnumbers,Ifwecan’texpresswhatweknowintheformofnumbers,wereallydon’tknowmuchaboutit.wereallydon’tknowmuchaboutit.•Ifwedon’tknowmuchaboutit,wecan’tcontrolit.Ifwedon’tknowmuchaboutit,wecan’tcontrolit.•Ifwecan’tcontrolit,weareatthemercyofchance.Ifwecan’tcontrolit,weareatthemercyofchance.MikelJ.HarryMikelJ.HarryPresident&CEOPresident&CEOSixSigmaAcademy,Inc.SixSigmaAcademy,Inc.ARigorousMethodforMeasuring&ControllingOurQualityARigorousMethodforMeasuring&ControllingOurQuality““......willbringGEtoawholenewlevelofqualityinafractionofthewillbringGEtoawholenewlevelofqualityinafractionofthetimeitwouldhavetakentoclimbthelearningcurveonourown.”timeitwouldhavetakentoclimbthelearningcurveonourown.”JohnF.Welch,Jr.JohnF.Welch,Jr.1995GEAnnualReport1995GEAnnualReport免费注册商,每天三小时推广,每月收入高达3000以上:注册网站:http://goodword.teasm.cn/旺昌资料城管理营销资料大全http://tb99888.taobao.com/QQ6024290866OverviewWhatDoes“Sigma”Mean?WhatDoes“Sigma”Mean?SigmaisaMeasureoftheConsistencyofaProcessSigmaisaMeasur...