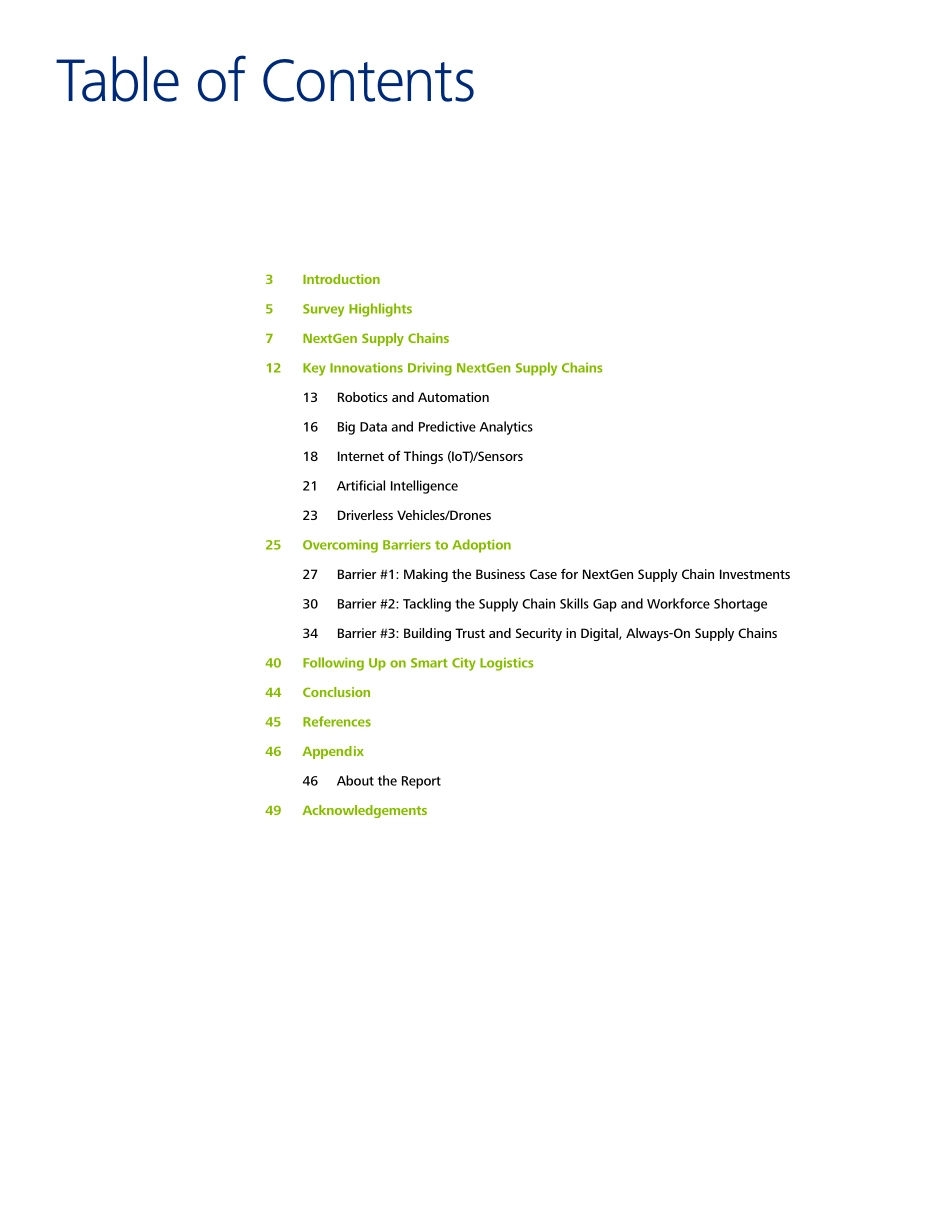

TableofContents3Introduction5SurveyHighlights7NextGenSupplyChains12KeyInnovationsDrivingNextGenSupplyChains13RoboticsandAutomation16BigDataandPredictiveAnalytics18InternetofThings(IoT)/Sensors21ArtificialIntelligence23DriverlessVehicles/Drones25OvercomingBarrierstoAdoption27Barrier#1:MakingtheBusinessCaseforNextGenSupplyChainInvestments30Barrier#2:TacklingtheSupplyChainSkillsGapandWorkforceShortage34Barrier#3:BuildingTrustandSecurityinDigital,Always-OnSupplyChains40FollowingUponSmartCityLogistics44Conclusion45References46Appendix46AbouttheReport49Acknowledgements73%RoboticsandAutomation65%TOPSUPPLYCHAININNOVATIONSTop7of11Potentialtodistruptorcreatecompetitiveadvantage.64%BARRIERSTOADOPTIONRoboticsandAutomationInternetofThingsDriverlessVehiclesandDronesArtificialIntelligence(Top3of8BarriersforEachTechnology)PredictiveAnalytics36%36%26%27%26%25%KeyLackofunderstandingoftechnologylandscapeLackofaccesstocapitaltomakeinvestmentsLackofclearbusinesscaseLackofadequatetalent28%19%17%29%26%17%25%24%15%CustomerdemandsonthesupplychainHiringqualifiedworkersPREPARATIONSActionsbeingtakentopreparefornextgenerationsupplychain.48%46%46%44%PartneringwithvendorstounderstandbenefitsIncreasedinvestment/budgetforemergingtechnologiesRecruitingfordifferentskillsetstoalignwithfutureneeds.TrainingworkforcetousenewtechnologiesOvercomingBarrierstoNextGenSupplyChainInnovation2018MHIAnnualIndustryReportKeySurveyFindingsTOPCHALLENGESWearableandMobileTechnology45%PredictiveAnalytics62%InternetofThings(IoT)59%ArtificialIntelligence53%InventoryandNetworkOptimization53%DriverlessVehiclesandDrones52%SUPPLYCHAINCYBERSECURITYRISKS40%44%37%Top3Sophisticationofhackersand“threatactors”LackofawarenesswithinorganizationPoorcybersecuritypracticesamongsuppliersCybersecuritytechnologycapitalbusinesscasetalentcybersecuritybusinesscasebusinesscasebusinesscasebusinesscasetalenttechnologytechnologytechnologytechnologycapitalADOPTIONRATE50%40%30%20%10%Sensors&AutomaticIdentificationRobotics&AutomationPredictiveAn...