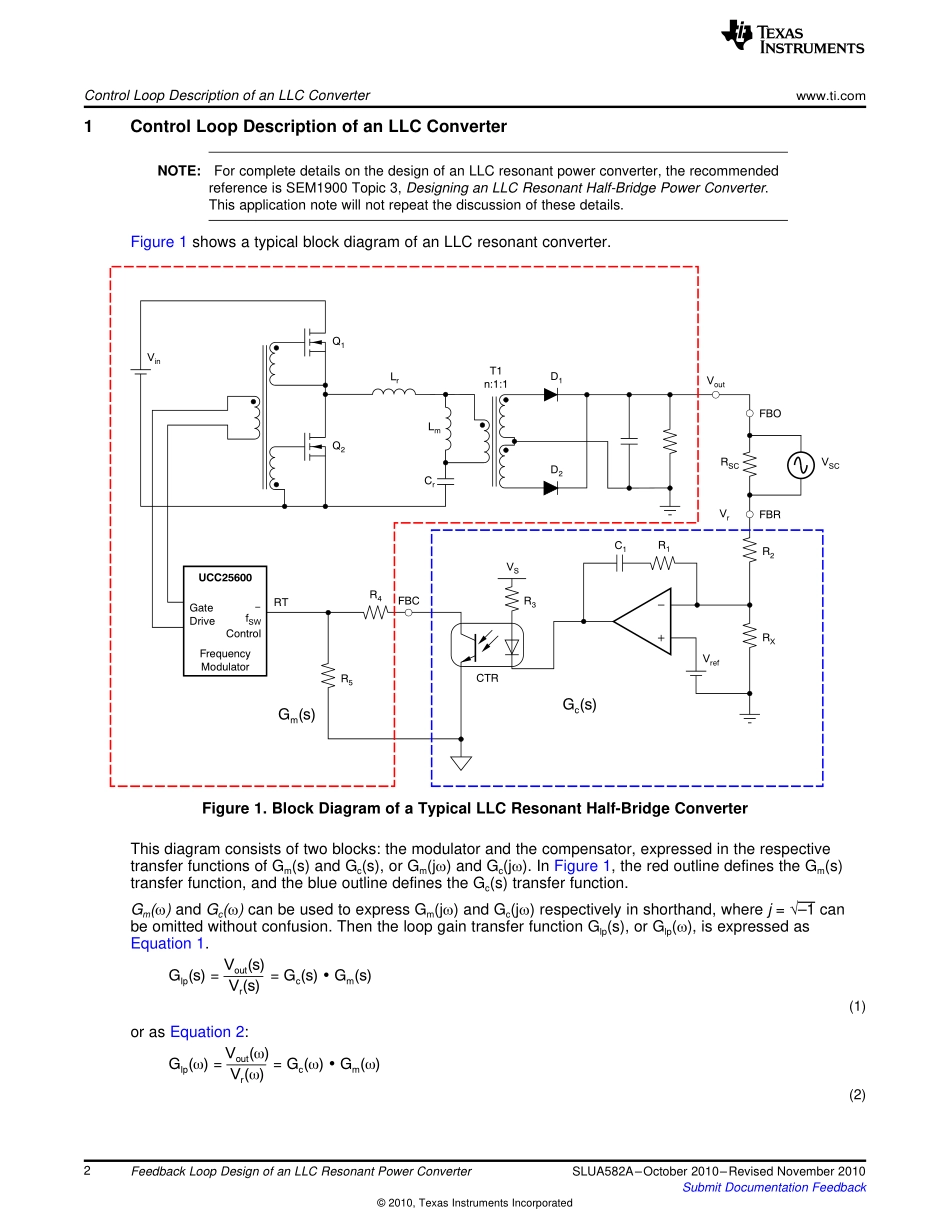

ApplicationReportSLUA582A–October2010–RevisedNovember2010FeedbackLoopDesignofanLLCResonantPowerConverterHongHuang.........................................................................................Power-SupplyControlProductsABSTRACTThisapplicationnotedescribesanapproachtodesignfeedbackloopcompensationforanLLCresonanthalf-bridgepowerconverter.TheapproachdescribedhereisbasedonthemeasuredBodeplotsofthemodulatorgeneratedbyanetworkanalyzer.Asweknow,aslongasthemodulatorBodeplotsareobtained,thefrequencydomainpolesandzerosinthefeedbackloopcompensationcanbeanalyticallydetermined,thenfine-tunedwithabenchtest.Thismeasurementisnecessaryaspartoffeedbackloopdesignbecauseapracticalsmall-signalmodelisnotavailableforLLCresonantconverters.ThisdocumentusestheTexasInstruments'UCC25600asthefrequencycontroller.AdetaileddescriptionoftheUCC25600anditsassociatedexampledesignfixture,theUCC25600EVM-341,canbefoundintheproductdatasheetandtheevaluationmoduleuser’sguide,respectively;bothadditionaldocumentsareavailablefordownloadatwww.ti.com.Contents1ControlLoopDescriptionofanLLCConverter.........................................................................22LoopCompensationDesignApproach...................................................................................43Methodology.................................................................................................................54References...................................................................................................................8ListofFigures1BlockDiagramofaTypicalLLCResonantHalf-BridgeConverter...................................................22AnotherWaytoDefineGm(w)andGc(w).................................................................................33InitialGm(w)Measurement.................................................................................................64Re-MeasurementofGm(w)....................................................................................................