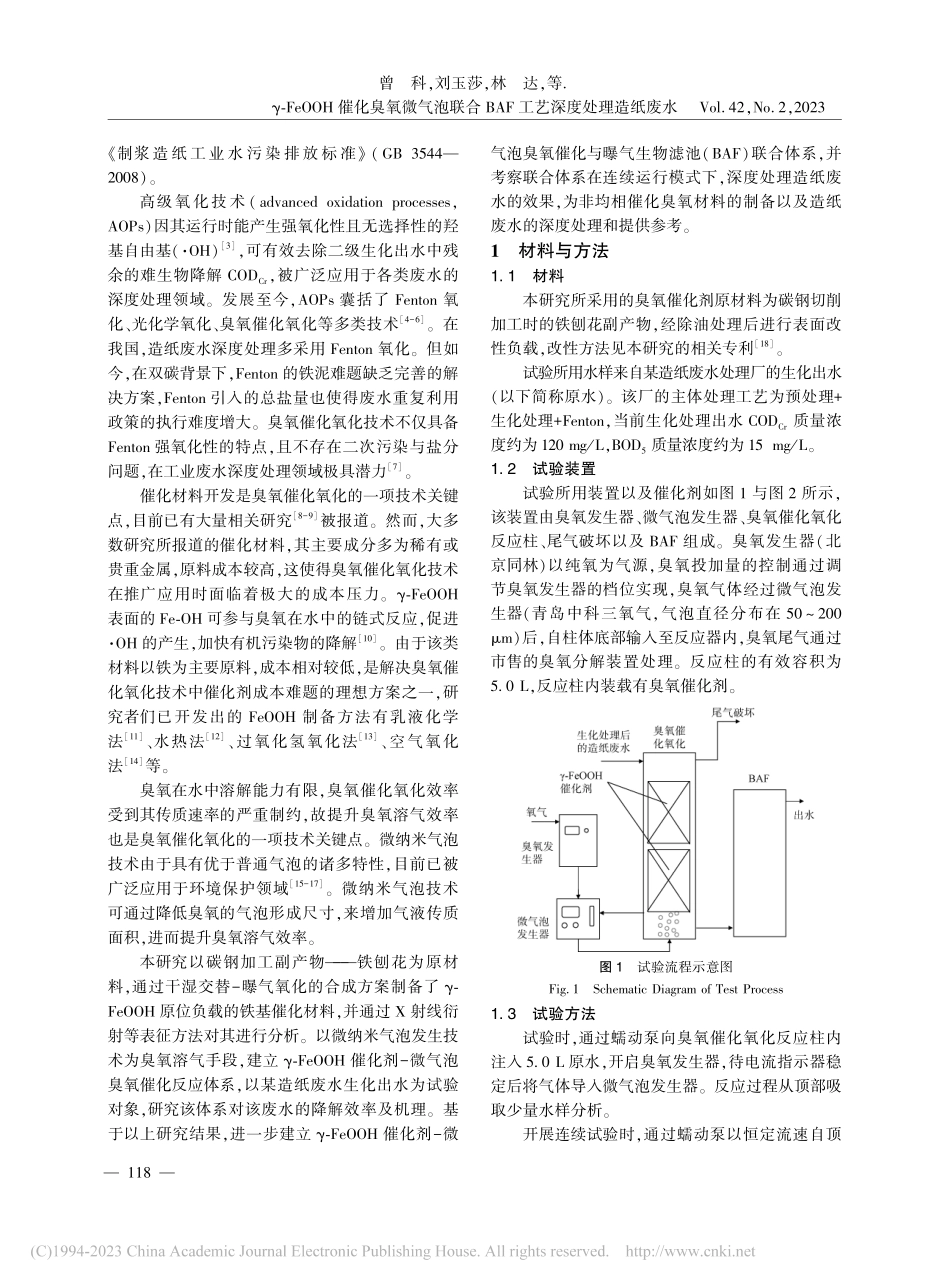

净水技术2023,42(2):117-124WaterPurificationTechnology曾科,刘玉莎,林达,等.γ-FeOOH催化臭氧微气泡联合BAF工艺深度处理造纸废水[J].净水技术,2023,42(2):117-124.ZENGK,LIUYS,LIND,etal.Advancedtreatmentofpapermakingwastewaterbycombinedprocessofγ-FeOOHcatalyzedozonemicrobubbleandBAF[J].WastewaterPurificationTechnology,2023,42(2):117-124.γ-FeOOH催化臭氧微气泡联合BAF工艺深度处理造纸废水曾科∗,刘玉莎,林达,陈文韬,黄成涛,陈剑(湖南博世科环保科技有限公司,湖南长沙410000)摘要随着“双碳”目标的制定以及造纸废水重复利用政策的颁布,开发清洁高效、无二次污染的造纸废水深度处理技术意义重大。研究通过干湿交替-曝气氧化的技术方案制备了铁基催化剂,XRD、XPS等表征结果显示该催化剂的表层负载物为纤铁矿(γ-FeOOH)。建立了γ-FeOOH催化臭氧微气泡的反应体系,并系统研究了该体系对造纸废水生化出水中CODCr的去除效果。试验结果显示,当pH值为7、催化剂投加量为300g/L、臭氧投加量为9.9mg/min时,该体系对CODCr的去除率约为58%。基于上述结果,进一步建立γ-FeOOH催化剂-臭氧微气泡催化与曝气生物滤池(BAF)的联合降解体系,该联合体系连续运行时,对造纸废水生化出水中CODCr去除率为60%~70%。该联合体系在有效降解有机污染物的同时,无二次污染产生,无总盐引入,有利于造纸废水的循环利用,践行了“双碳”理念。关键词纤铁矿(γ-FeOOH)微气泡催化臭氧造纸废水曝气生物滤池深度处理中图分类号:TQ09文献标识码:A文章编号:1009-0177(2023)02-0117-08DOI:10.15890/j.cnki.jsjs.2023.02.015AdvancedTreatmentofPapermakingWastewaterbyCombinedProcessofγ-FeOOHCata-lyzedOzoneMicrobubbleandBAFZENGKe∗,LIUYusha,LINDa,CHENWentao,HUANGChengtao,CHENJian(HunanBosscoEnvironmentalProtectionTechnologyCo.,Ltd.,Changsha410000,China)AbstractWiththeformulationofthe"double-carbon"goalandthepromulgationofthepapermakingwastewaterreusepolicy,itisgreatsignificancetodevelopaclean,efficient,andnon-secondarypollutionadvancedtreatmenttechnologyforpapermakingwastewater.Iron-basedcatalystwaspreparedbythetechnicalschemeofalternatingdryandwet-aerationoxidationinthestudy.ThecharacterizationofXRD、XPSandothermehodsshowedthatthesurfacematerialofthecatalystwaslepidocrocite(γ-FeOOH).Thesystemofcatalyticmicrobu...