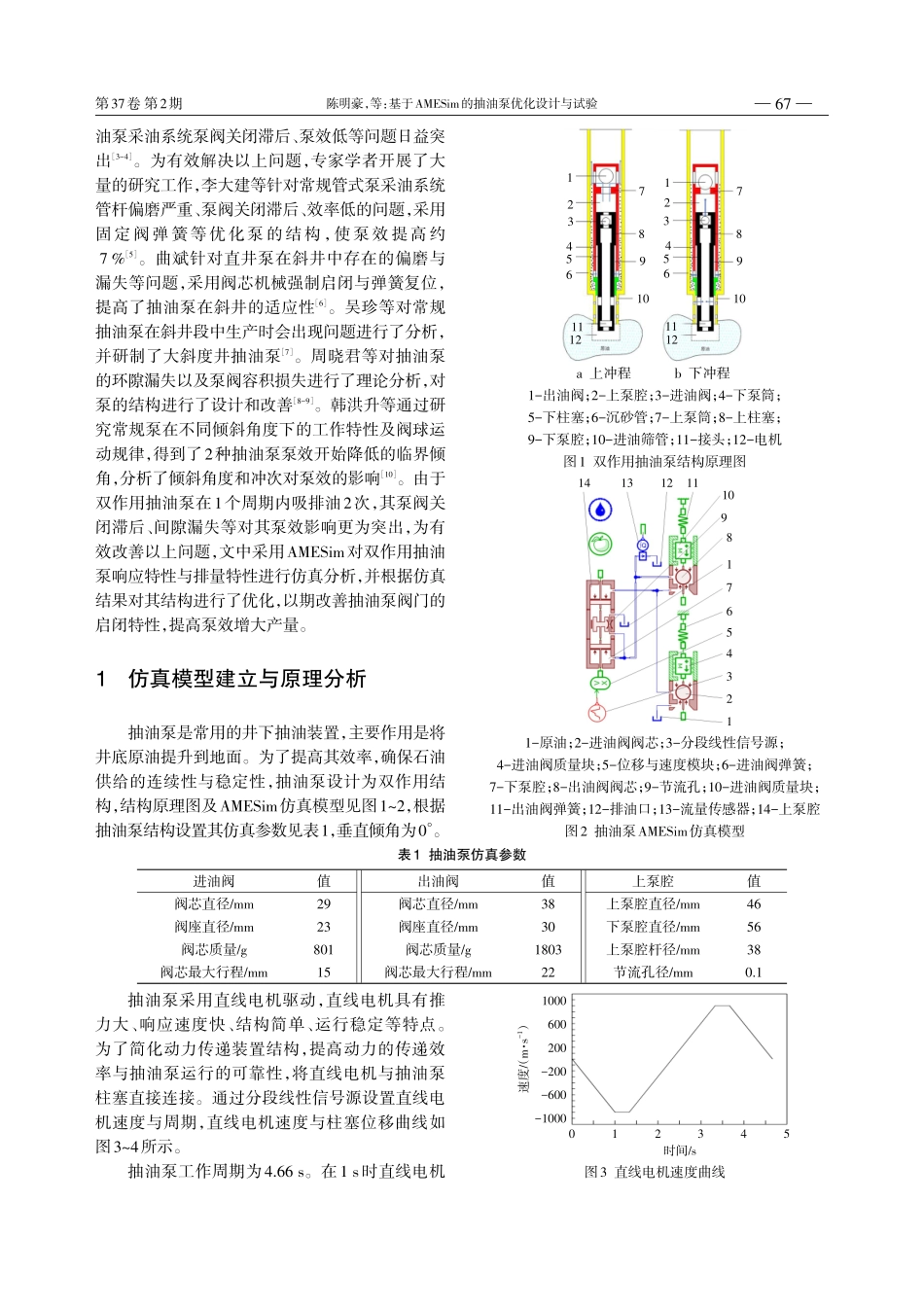

湖北汽车工业学院学报JournalofHubeiUniversityofAutomotiveTechnology第37卷第2期2023年6月Vol.37No.2Jun.2023doi:10.3969/j.issn.1008-5483.2023.02.014基于AMESim的抽油泵优化设计与试验陈明豪1,陆锦锦1,陆婕1,杨凯2,刘元1,严谨3(1.武汉第二船舶设计研究所,湖北武汉430064;2.湖北第二师范学院物理与机电工程学院,湖北武汉430205;3.广东海洋大学海洋工程与能源学院,广东湛江524029)摘要:针对常规抽油泵存在泵阀关闭滞后、泵效低等问题,采用AMESim建立了抽油泵仿真模型,并对柱塞的漏失量、出油阀阀芯位移及阀口流量等响应特性与排量特性进行了分析。对抽油泵进行了结构优化,通过在出油阀阀芯上安装弹簧与机械限位,降低了出油阀阀芯的关闭时间,减少了油液溢出对其排量产生的影响。进一步分析了不同弹簧刚度与不同垂直倾角对出油阀阀芯量位移的影响。试验结果表明:抽油泵排量具有良好的线性度与稳定性,优化后排量较优化前排量提高约15%。关键词:石油钻采;斜井;抽油泵;AMESim仿真中图分类号:TE933.3文献标识码:A文章编号:1008-5483(2023)02-0066-05OptimizationandExperimentofOilWellPumpBasedonAMESimChenMinghao1,LuJinjin1,LuJie1,YangKai2,LiuYuan1,YanJin3(1.WuhanSecondShipDesignandResearchInstitute,Wuhan430064,China;2.SchoolofPhysicsandMechanical&ElectricalEngineering,HubeiUniversityofEducation,Wuhan430205,China;3.CollegeofOceanEngineeringandEnergy,GuangdongOceanUniversity,Zhanjiang524029,China)Abstract:Inviewoftheproblemsofdelayedpumpvalveclosingandlowpumpefficiencyofconven‐tionaloilwellpumps,asimulationmodeloftheoilwellpumpwasestablishedbyusingAMESim.Theresponseanddisplacementcharacteristicsoftheplungerleakage,displacementoftheoiloutletvalve’score,andflowrateofthevalveportwereanalyzed.Thestructureoftheoilwellpumpwasoptimized.Byinstallingaspringandamechanicallimitontheoiloutletvalve’score,theclosingtimeoftheoiloutletvalve’scorewasreduced,andtheinfluenceofoiloverflowonthedisplacementwasalleviated.Thein‐fluenceofdifferentspringstiffnessandverticalinclinationonthedisplacementoftheoiloutletvalve’scorewasfurtheranalyzed.Thetestresultsshowthatthedisplacementoftheoilwellpumphasexcellentlinearityandstability,andthed...