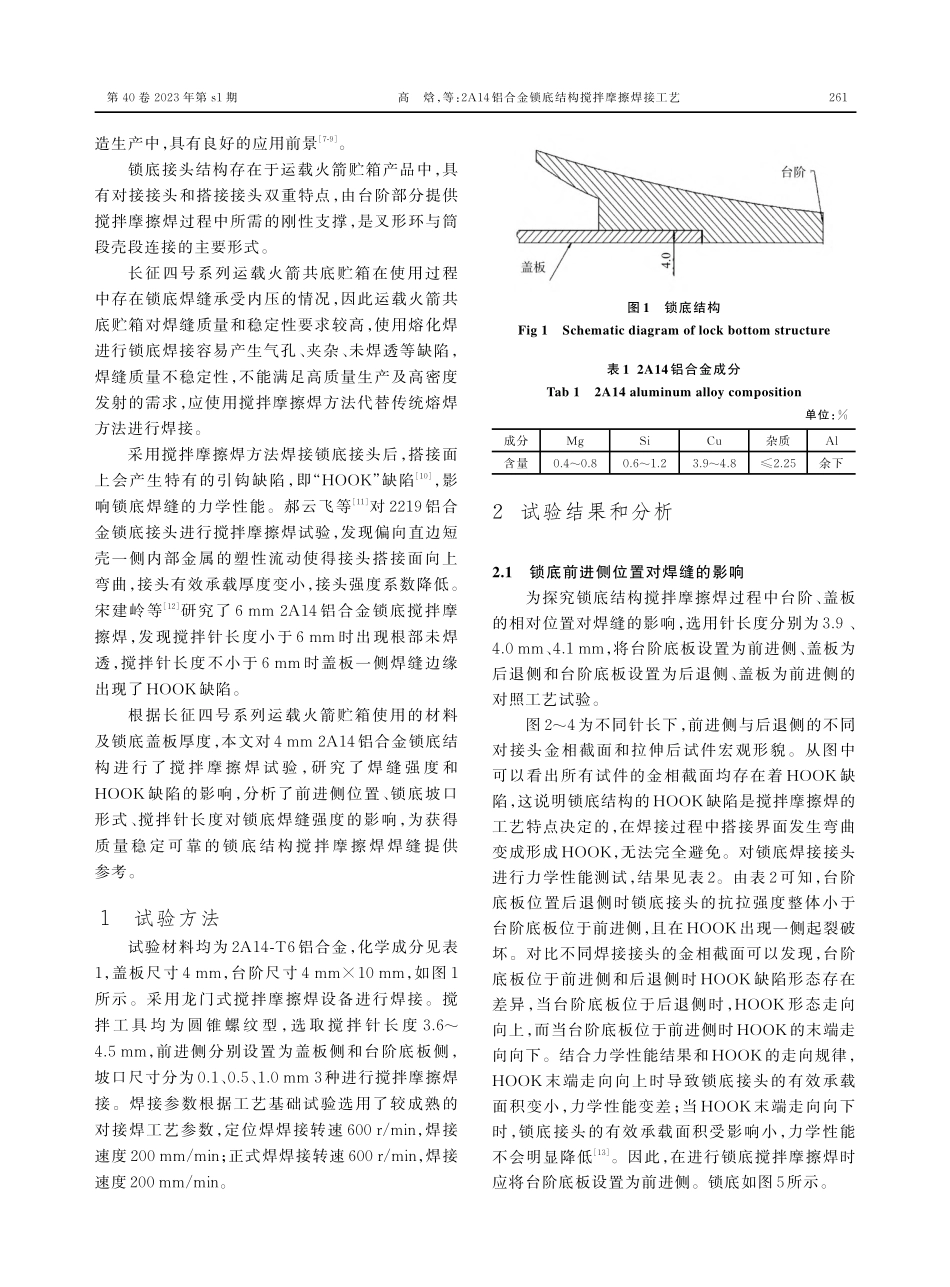

第40卷2023年第s1期上海航天(中英文)AEROSPACESHANGHAI(CHINESE&ENGLISH)2A14铝合金锁底结构搅拌摩擦焊接工艺高焓,张聃,周佳芬,赵慧慧,何健利,尹玉环(上海市航天设备制造总厂有限公司,上海,200245)摘要:针对运载火箭共底贮箱独特的密封锁底焊缝承压结构开展搅拌摩擦焊工艺技术研究,采用基于锁底结构搅拌工具设计的无匙孔回抽全焊透工艺技术,探究搅拌针长度、前进侧位置、坡口尺寸对4mm2A14铝合金锁底焊缝强度的影响。经过焊接试验验证,针长度为−0.1~0.3mm,前进侧位于锁底侧,焊接坡口设为0.5mm时为最优焊接工艺参数,焊缝强度高于熔焊焊缝强度。对锁底焊缝引钩(HOOK)缺陷进行研究,抑制了HOOK的产生,实现了搅拌摩擦焊方法在运载火箭承压锁底结构的首次应用与飞行验证,提高了焊接效率和质量,并实现整箱减重。关键词:共底贮箱;搅拌摩擦焊;锁底焊缝中图分类号:TG453.9文献标志码:ADOI:10.19328/j.cnki.2096⁃8655.2023.s1.0382A14AluminumAlloyBottomLockStructureFrictionStirWeldingProcessGAOHan,ZHANGDan,ZHOUJiafen,ZHAOHuihui,HEJianli,YINYuhuan(ShanghaiAerospaceEquipmentManufacturingGeneralFactoryCo.,Ltd.,Shanghai,200245)Abstract:Aimingattheuniquesealedbottom-lockweldpressure-bearingstructureofalaunchvehicle'scommonbottomstoragetank,thefrictionstirweldingtechnologywasstudied.Thekeylessholeretractionfullweldingpenetrationprocesstechnologywhichwasdesignedbasedonthelock-bottomstructurestirringtoolwasappliedtostudytheeffectsofstirringneedlelength,forwardsidepositionandgroovesizeonthestrengthofa4mm2A14aluminumalloylock-bottomweld.Accordingtotheweldingverificationtests,underthescenariothattheforwardsidewaslocatedonthebottomsideofthelockwhenthelengthoftheelectedneedlewassetbetween-0.1mm~+0.3mmandtheweldinggroovewassetto0.5mm,theoptimalweldingprocesscanbeachievedandtheweldstrengthwashigherthanthefusionweldstrength.FurtherstudyonthehookofthelockbottomweldinhibitsthegenerationofHOOKhasrealizedthefirstapplicationandflightverificationoffrictionstirweldingmethodinthepressure-bearingbottomlockstructureofthelaunchvehicle,thusimprovingtheweldingefficiency,quality,andtheheavyweightofthewholecontainer.Keywords:tan...