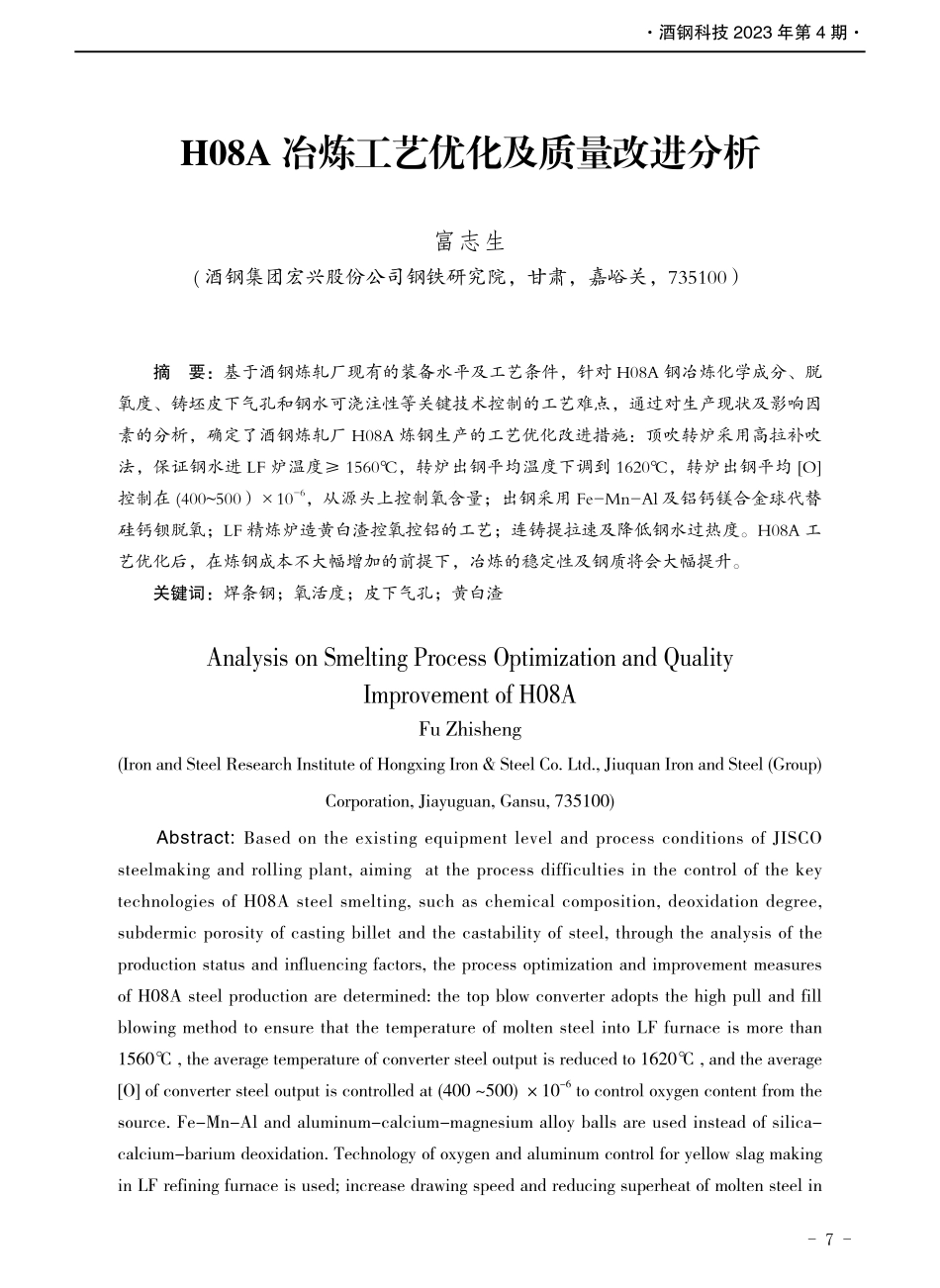

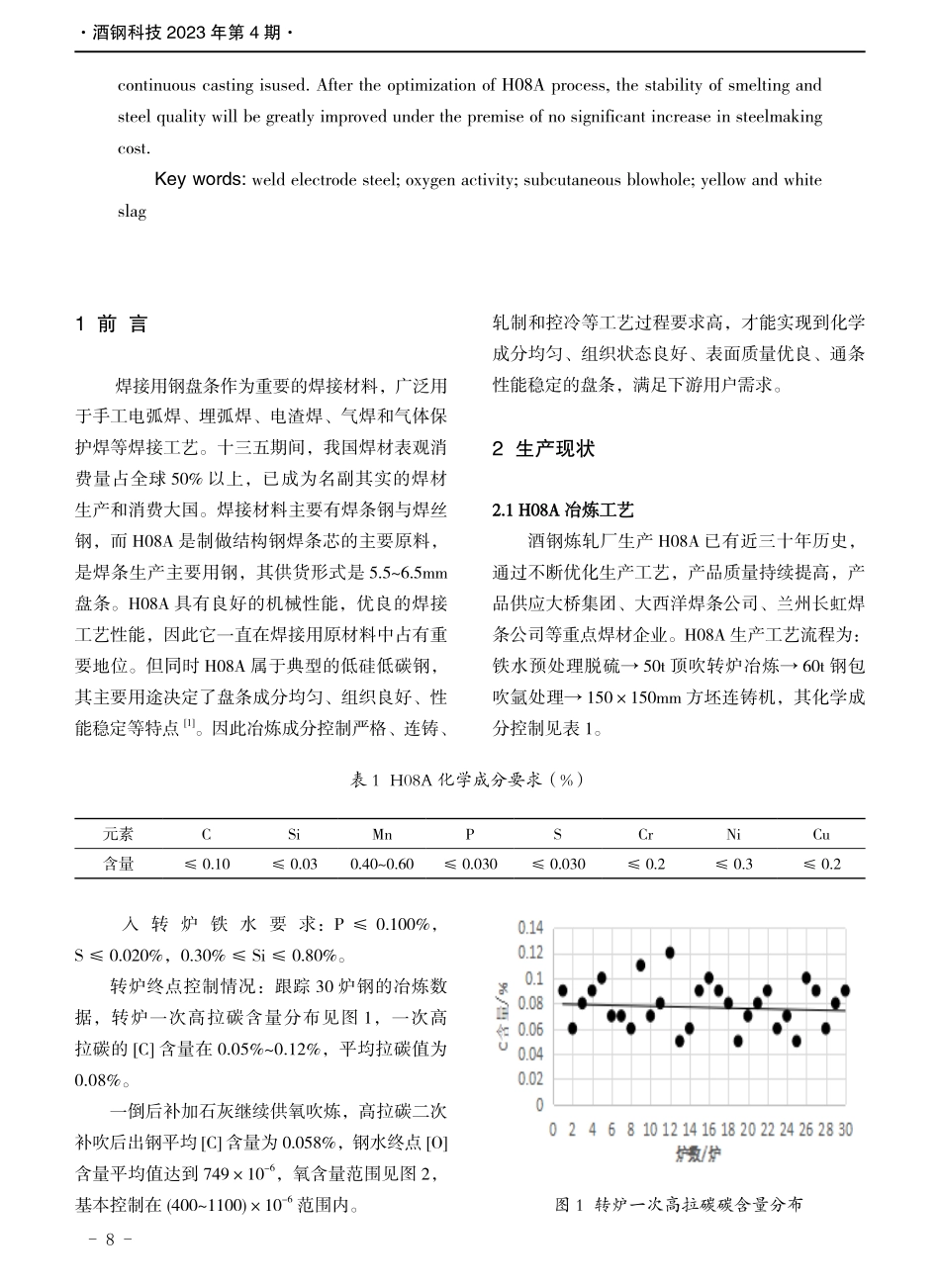

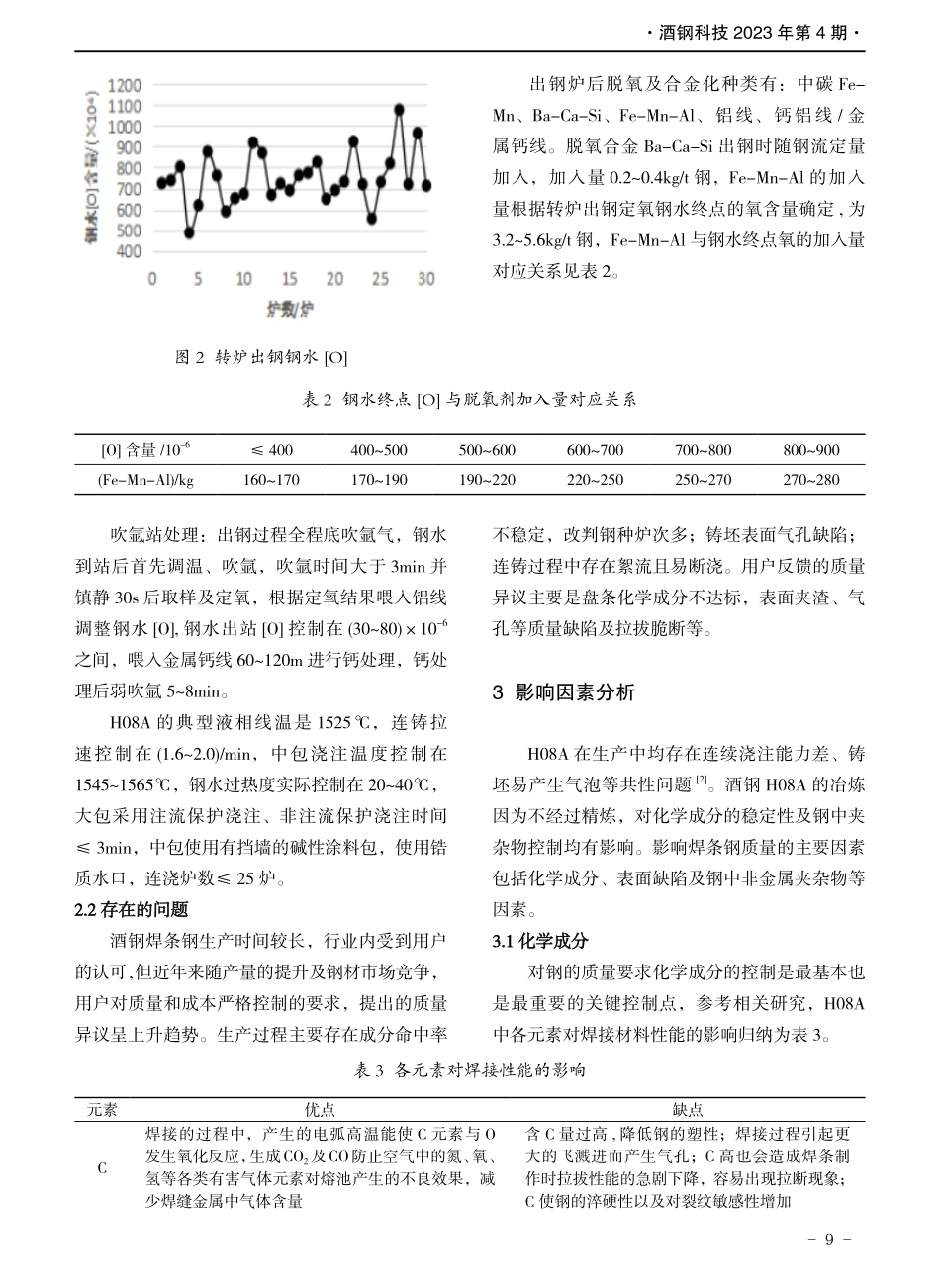

·酒钢科技2023年第4期·-7-H08A冶炼工艺优化及质量改进分析富志生(酒钢集团宏兴股份公司钢铁研究院,甘肃,嘉峪关,735100)摘要:基于酒钢炼轧厂现有的装备水平及工艺条件,针对H08A钢冶炼化学成分、脱氧度、铸坯皮下气孔和钢水可浇注性等关键技术控制的工艺难点,通过对生产现状及影响因素的分析,确定了酒钢炼轧厂H08A炼钢生产的工艺优化改进措施:顶吹转炉采用高拉补吹法,保证钢水进LF炉温度≥1560℃,转炉出钢平均温度下调到1620℃,转炉出钢平均[O]控制在(400~500)×10-6,从源头上控制氧含量;出钢采用Fe-Mn-Al及铝钙镁合金球代替硅钙钡脱氧;LF精炼炉造黄白渣控氧控铝的工艺;连铸提拉速及降低钢水过热度。H08A工艺优化后,在炼钢成本不大幅增加的前提下,冶炼的稳定性及钢质将会大幅提升。关键词:焊条钢;氧活度;皮下气孔;黄白渣AnalysisonSmeltingProcessOptimizationandQualityImprovementofH08AFuZhisheng(IronandSteelResearchInstituteofHongxingIron&SteelCo.Ltd.,JiuquanIronandSteel(Group)Corporation,Jiayuguan,Gansu,735100)Abstract:BasedontheexistingequipmentlevelandprocessconditionsofJISCOsteelmakingandrollingplant,aimingattheprocessdifficultiesinthecontrolofthekeytechnologiesofH08Asteelsmelting,suchaschemicalcomposition,deoxidationdegree,subdermicporosityofcastingbilletandthecastabilityofsteel,throughtheanalysisoftheproductionstatusandinfluencingfactors,theprocessoptimizationandimprovementmeasuresofH08Asteelproductionaredetermined:thetopblowconverteradoptsthehighpullandfillblowingmethodtoensurethatthetemperatureofmoltensteelintoLFfurnaceismorethan1560℃,theaveragetemperatureofconvertersteeloutputisreducedto1620℃,andtheaverage[O]ofconvertersteeloutputiscontrolledat(400~500)×10-6tocontroloxygencontentfromthesource.Fe-Mn-Alandaluminum-calcium-magnesiumalloyballsareusedinsteadofsilica-calcium-bariumdeoxidation.TechnologyofoxygenandaluminumcontrolforyellowslagmakinginLFrefiningfurnaceisused;increasedrawingspeedandreducingsuperheatofmoltensteelin·酒钢科技2023年第4期·-8-表1H08A化学成分要求(%)图1转炉一次高拉碳碳含量分布continuouscastingisused.AftertheoptimizationofH08Aprocess,thestabilityofsmeltingandsteelqualityw...