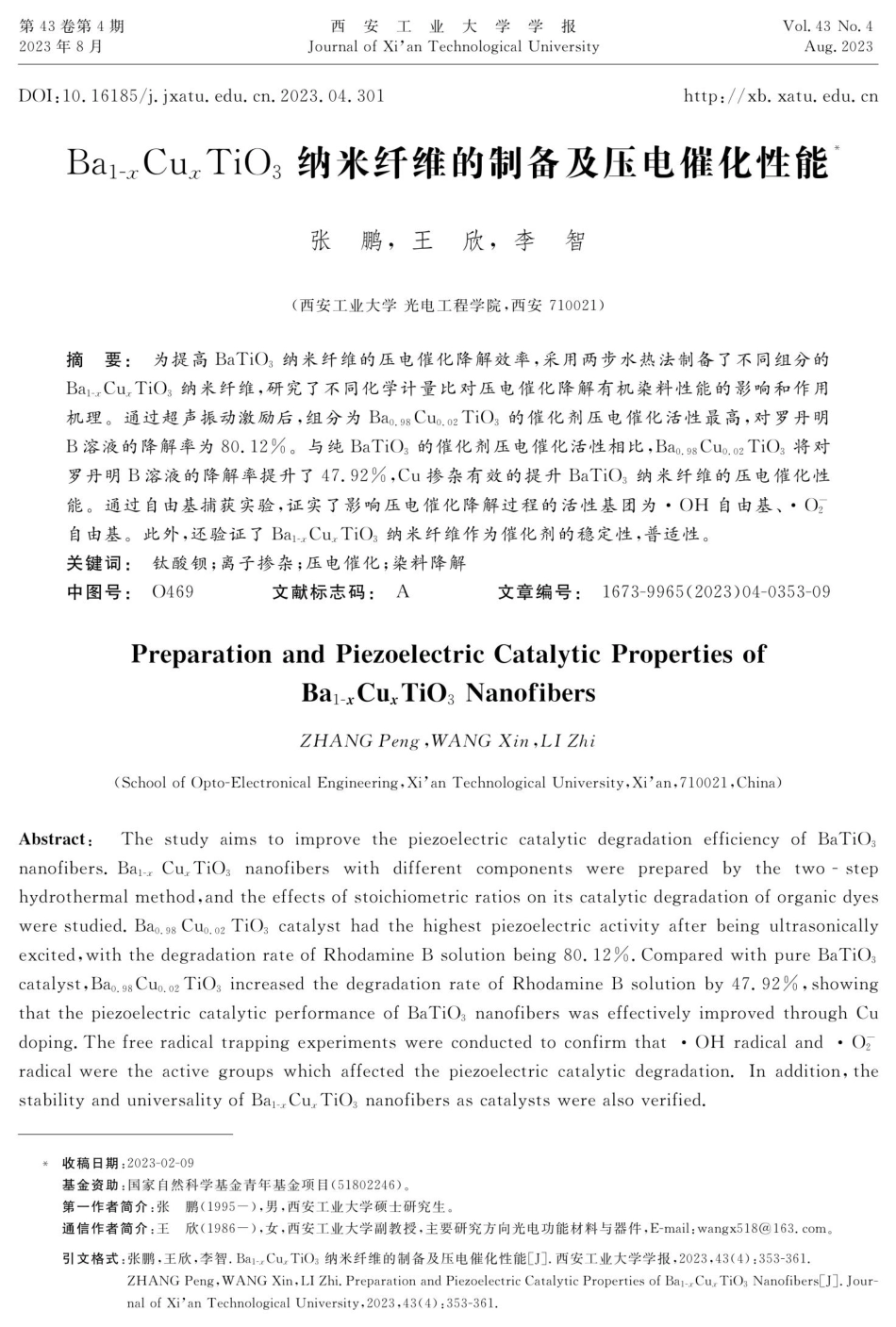

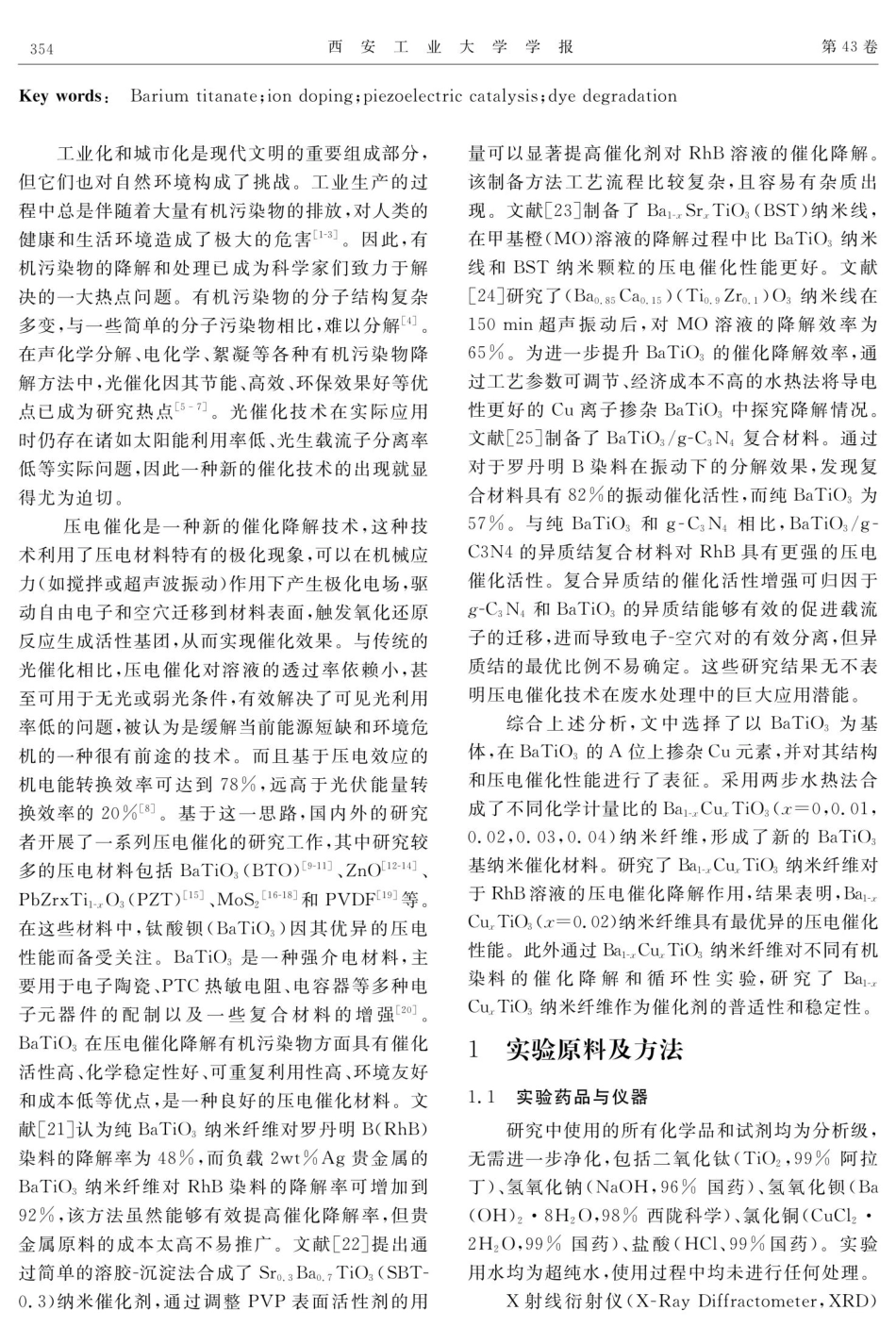

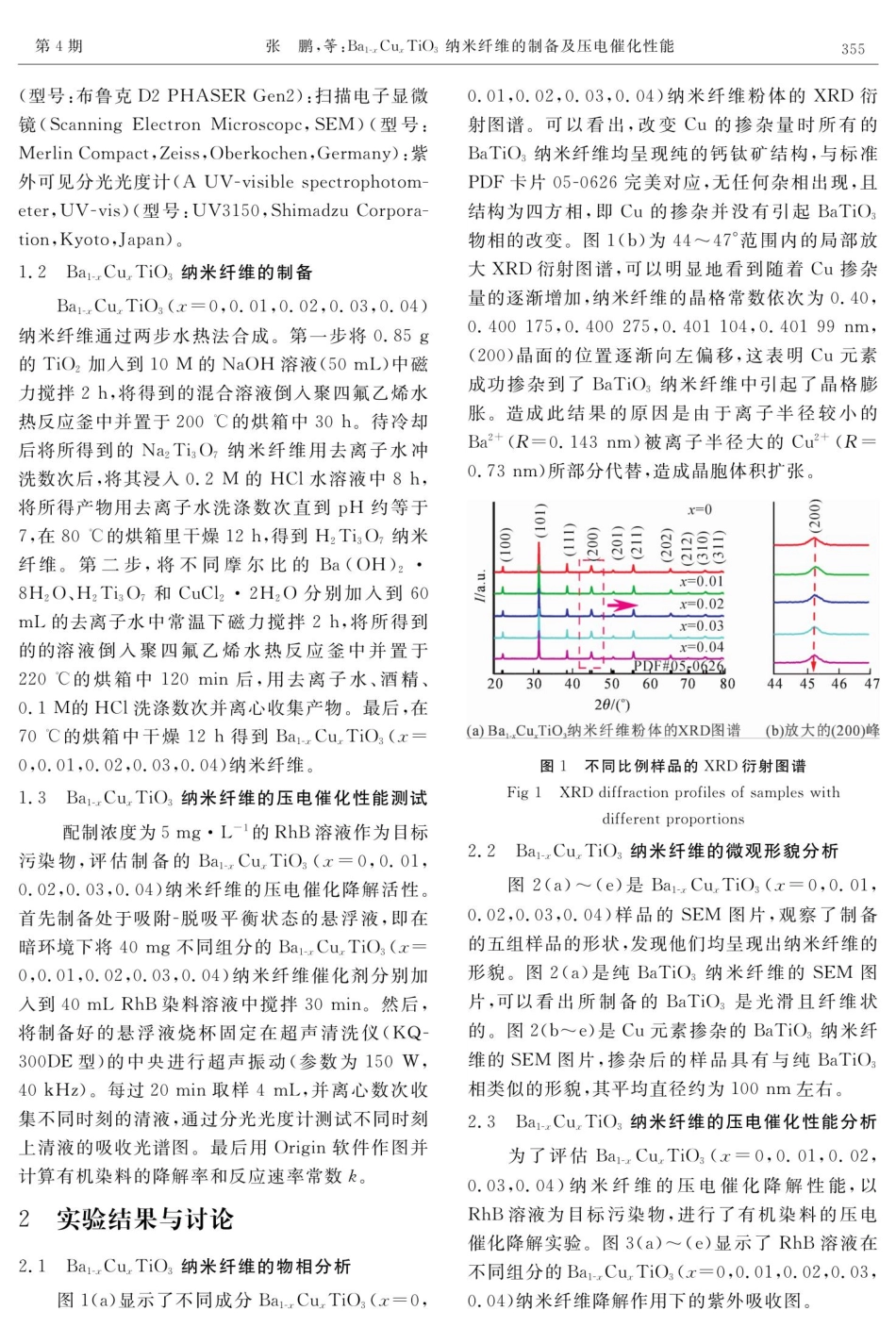

第43卷第4期2023年8月DOI:10.16185/j.jxatu.edu.cn.2023.04.301Ba1-sCu.TiO:纳米纤维的制备及压电催化性能西安工业大学学报JournalofXi'anTechnologicalUniversityVol.43No.4Aug.2023http://xb.xatu.edu.cn张鹏,王欣,李智(西安工业大学光电工程学院,西安710021)摘要:为提高BaTiO:纳米纤维的压电催化降解效率,采用两步水热法制备了不同组分的Bai-Cu,TiO:纳米纤维,研究了不同化学计量比对压电催化降解有机染料性能的影响和作用机理。通过超声振动激励后,组分为Bao.98Cuo.02TiO:的催化剂压电催化活性最高,对罗丹明B溶液的降解率为80.12%。与纯BaTiO:的催化剂压电催化活性相比,Bao.98Cuo.02TiO:将对罗丹明B溶液的降解率提升了47.92%,Cu掺杂有效的提升BaTiO:纳米纤维的压电催化性能。通过自由基捕获实验,证实了影响压电催化降解过程的活性基团为·OH自由基、·O2自由基。此外,还验证了Bal-rCu,TiO3纳米纤维作为催化剂的稳定性,普适性。关键词:钛酸钡;离子掺杂;压电催化;染料降解中图号:0469文献标志码:APreparationandPiezoelectricCatalyticPropertiesofBai-CuxTiO:NanofibersZHANGPeng,WANGXin,LIZhi(SchoolofOpto-ElectronicalEngineering,Xi'anTechnologicalUniversity,Xi'an,710021,China)Abstract:ThestudyaimstoimprovethepiezoelectriccatalyticdegradationefficiencyofBaTiO3nanofibers.Bai-Cu,TiOsnanofiberswithdifferentcomponentswerepreparedbythetwo-stephydrothermalmethod,andtheeffectsofstoichiometricratiosonitscatalyticdegradationoforganicdyeswerestudied.Bao.9sCuo.02TiO:catalysthadthehighestpiezoelectricactivityafterbeingultrasonicallyexcited,withthedegradationrateofRhodamineBsolutionbeing80.12%.ComparedwithpureBaTiO;catalyst,Bao.98Cuo.02TiO,increasedthedegradationrateofRhodamineBsolutionby47.92%,showingthatthepiezoelectriccatalyticperformanceofBaTiOsnanofiberswaseffectivelyimprovedthroughCudoping.Thefreeradicaltrappingexperimentswereconductedtoconfirmthat·OHradicaland·O2radicalweretheactivegroupswhichaffectedthepiezoelectriccatalyticdegradation.Inaddition,thestabilityanduniversalityofBai--Cu,TiO,nanofibersascatalystswerealsoverified.文章编号:1673-9965(2023)04-0353-09*收稿日期:2023-02-09基金资助:国家自然科学基金青年基金项目(51...