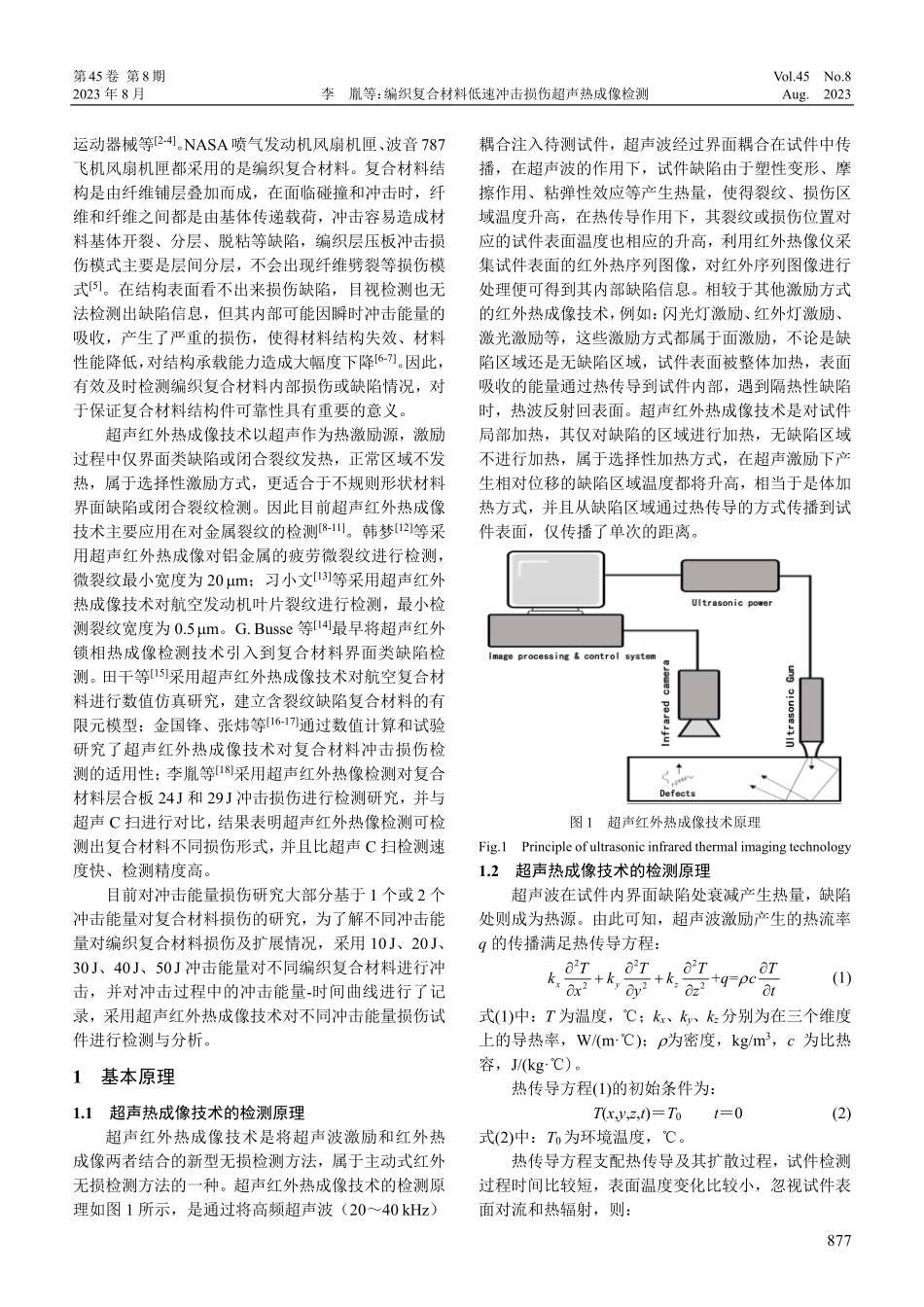

第45卷第8期红外技术Vol.45No.82023年8月InfraredTechnologyAug.2023876〈无损检测〉编织复合材料低速冲击损伤超声热成像检测李胤1,宋远佳1,江海军2,陈飞2,张凯2(1.中国空气动力研究与发展中心,四川绵阳621000;2.南京诺威尔光电系统有限公司,江苏南京210014)摘要:编织复合材料低速冲击损伤主要为内部的分层损伤,采用目视检测无法有效检测损伤,损伤使得结构承载能力严重降低,威胁编织复合材料构件的安全使用。本文使用超声红外热成像技术对编织复合材料低速冲击损伤进行无损检测研究,使用10J、20J、30J、40J、50J的冲击能量制作了5个试件。对超声激励过程的温升曲线、空间温度曲线进行了详细分析;对比不同冲击能量试件发现,低速冲击下损伤主要是内部损伤,冲击能量越大,损伤区域越大,且损伤具有延展性。采用曲线分类算法对损伤区域进行了定量识别,发现编织复合材料损伤面积和冲击能量成线性关系。关键词:超声红外热成像;编织复合材料;低速冲击损伤;无损检测中图分类号:V45文献标志码:A文章编号:1001-8891(2023)08-0876-08Low-velocityImpactDamageDetectionofWovenCompositesBasedonUltrasonicInfraredThermographyLIYin1,SONGYuanjia1,JIANGHaijun2,CHENFei2,ZHANGKai2(1.ChinaAerodynamicsResearchandDevelopmentCenter,Mianyang621000,China;2.NovelteqLtd.,Nanjing210014,China)Abstract:Low-velocityimpactdamageofwovencompositesismainlycausedbyinternaldelaminationdamage,whichcannotbeeffectivelydetectedbyvisualinspection;thisseriouslyreducesthestructuralload-bearingcapacityandthreatensthesafeuseofthecompiledcompositecomponents.Inthisstudy,ultrasonicinfraredthermographywasusedtoperformnondestructivetestingofthelow-velocityimpactdamageofwovencomposites,andfivespecimenswereproducedusingimpactenergiesof10,20,30,40,and50J.Thetemperatureincreaseandspacetemperaturecurvesoftheultrasonicexcitationprocesswereanalyzed.Bycomparingdifferentimpactenergyspecimens,itwasfoundthatthedamageunderlow-speedimpactwasmainlyinternal,andthelargertheimpactenergy,thelargerthedamagearea.Moreover,thedamagewasductile.Thedamageareawasidentifiedquantitativelyusingacurveclassificationalgorithm.Itwasfoundthatthedamageareaofwovencompositesandtheimpactenergywerelinearl...