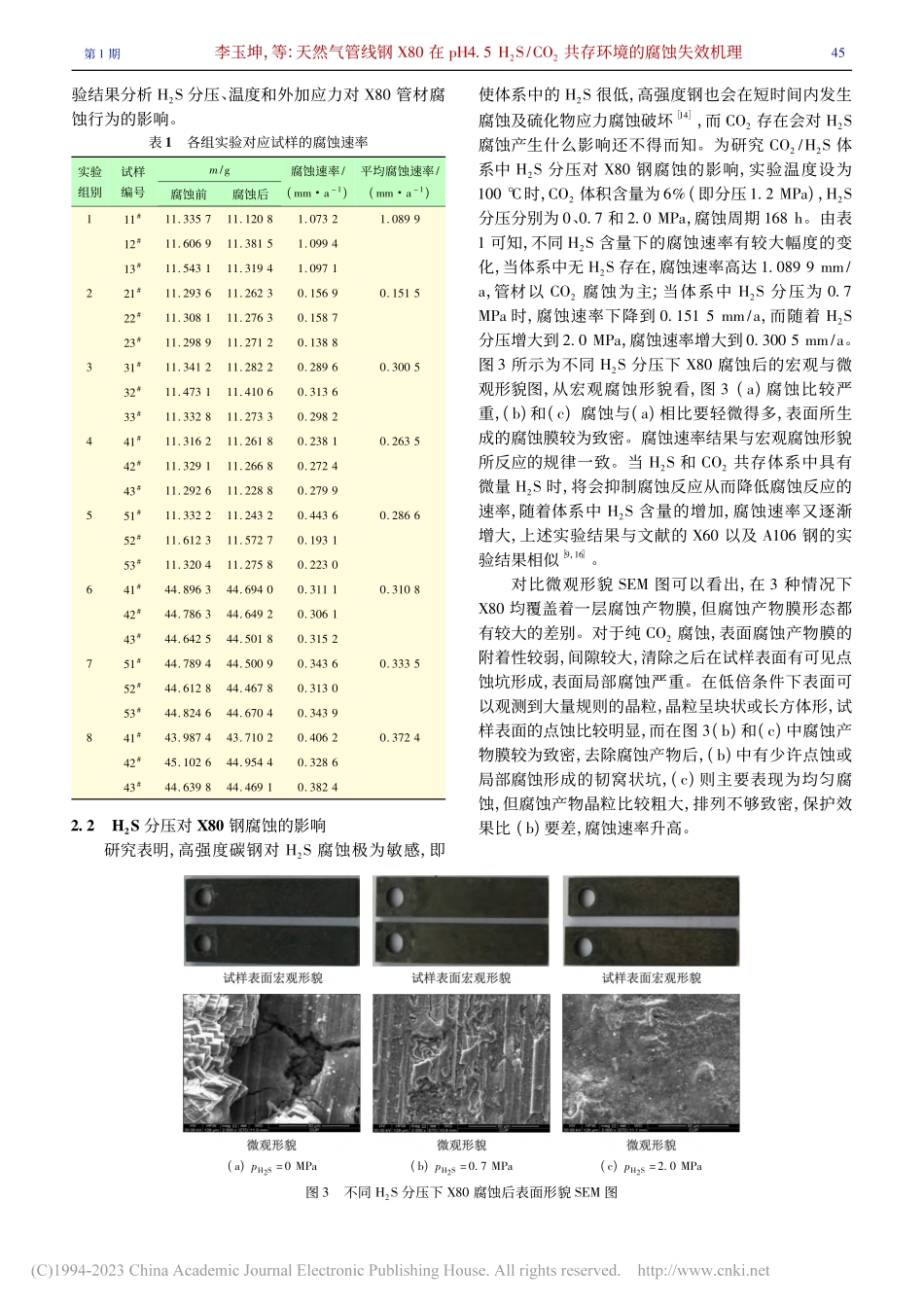

ISSN1006-7167CN31-1707/TRESEARCHANDEXPLORATIONINLABORATORY第42卷第1期Vol.42No.12023年1月Jan.2023DOI:10.19927/j.cnki.syyt.2023.01.009天然气管线钢X80在pH4.5H2S/CO2共存环境的腐蚀失效机理李玉坤,黄小光,周龙池,彭启凤(中国石油大学(华东)储运与建筑工程学院,山东青岛266580)摘要:针对天然气管道的内腐蚀问题,利用高温高压反应釜模拟了低pH值及H2S/CO2共存环境,结合SEM、EDS以及XRD技术探讨了H2S分压、实验温度以及外加应力对X80管线钢的腐蚀速率与腐蚀机理的影响。结果表明,纯CO2腐蚀远较H2S/CO2共存时严重;含H2S条件下,腐蚀产物膜中非晶态Cr(OH)3能提升FeS膜的稳定性,起到表面保护和降低腐蚀速率作用。H2S/CO2共存时,X80管材发生H2S腐蚀反应为主的均匀腐蚀,腐蚀速率随H2S分压增大而升高;腐蚀速率随着环境温度的增加先增后减,在设定的实验条件下,最高的腐蚀速率发生在100℃附近;外加应力对腐蚀速率影响显著,腐蚀速率随应力增加快速升高。关键词:天然气管线;X80钢;腐蚀速率;温度;应力中图分类号:TG172.3文献标志码:A文章编号:1006-7167(2023)01-0043-06CorrosionFailureMechanismofNaturalGasPipelineSteelX80inapH4.5H2S/CO2CoexistenceEnvironmentLIYukun,HUANGXiaoguang,ZHOULongchi,PENGQifeng(CollegeofPipelineandCivilEngineering,ChinaUniversityofPetroleum,Qingdao266580,Shandong,China)Abstract:Internalcorrosionofpipelineisanimportantfactoraffectingthesafetyofnaturalgastransmission.Ahightemperature-pressurereactorisusedtosimulatethelowpHH2S/CO2coexistenceenvironment,andtheeffectsofH2Spartialpressure,experimentaltemperatureandappliedstressonthecorrosionrateandcorrosionmechanismofAPIX80steelarediscussed,combinedwithSEM,EDSandXRDtechniques.TheresultsshowthatthecorrosionofthesamplesunderpureCO2conditionismuchseriousthanthatunderH2S/CO2coexistence.ThecorrosionstabilityofamorphousfilmunderH2S-containingenvironmentcanbeimprovedtobytheformationofamorphousCr(OH)3,thereforethesurfaceprotectionismoreobviousthanthatinpureCO2condition.TheX80steelissubjecttouniformcorrosiondominatedbyH2Scorrosion,andthecorrosionrateincreaseswiththeincreaseofH2Spartialpressure.Thecorrosionratefirstlyincreasesandthendecrease...