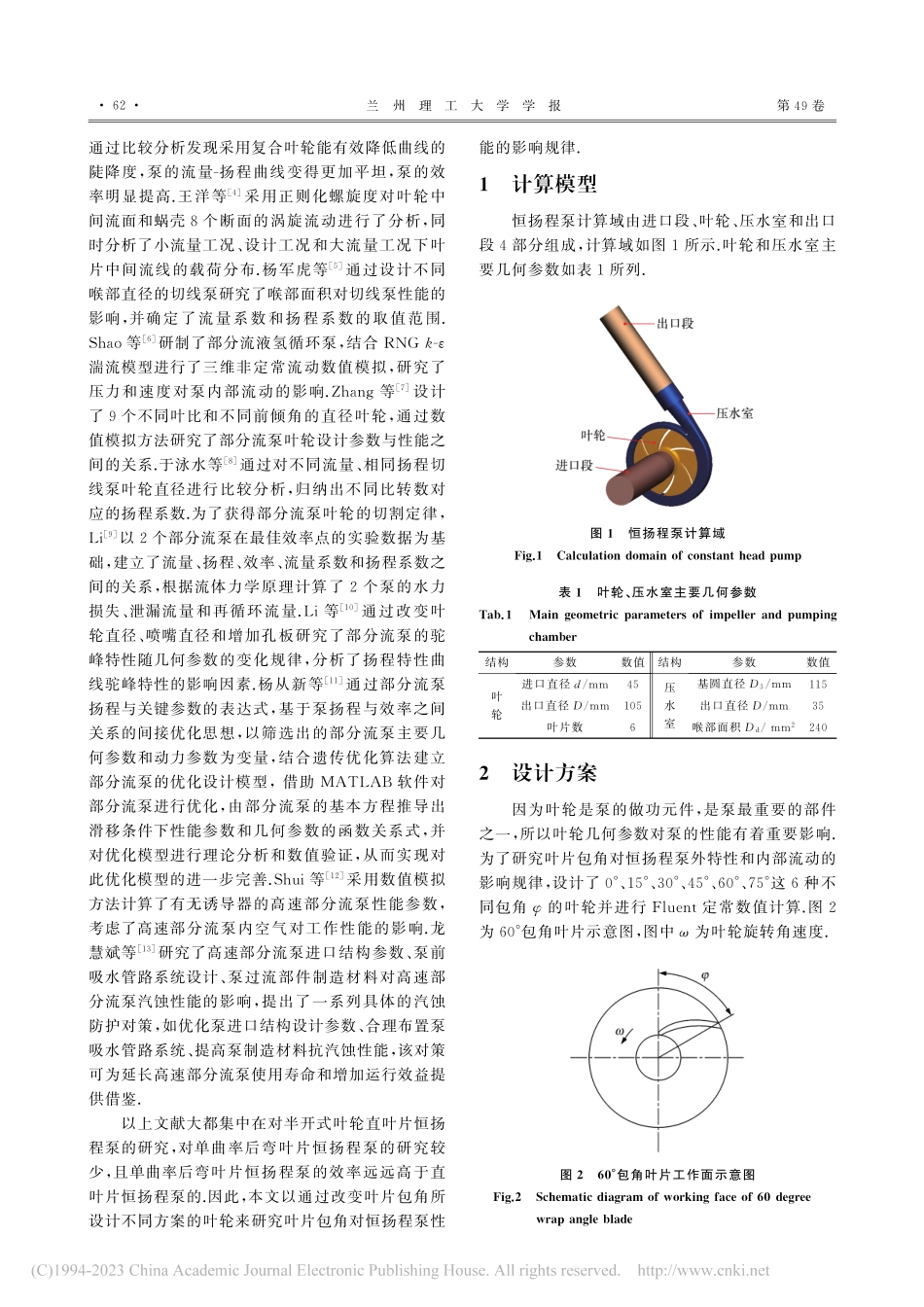

文章编号:1673-5196(2023)01-0061-08叶片包角对恒扬程泵性能的影响程效锐1,2,田龙*1,李天鹏3,杨登峰4(1.兰州理工大学能源与动力工程学院,甘肃兰州730050;2.兰州理工大学甘肃省流体机械及系统重点实验室,甘肃兰州730050;3.武汉航达航空科技发展有限公司,湖北武汉430010;4.上海大学力学与工程科学学院,上海200072)摘要:为了研究叶片包角对恒扬程泵性能的影响规律,设计了6种不同包角叶片的叶轮,基于雷诺时均N-S方程、RNGk-ε湍流模型进行了定常数值计算,并对计算结果进行了实验验证.结果表明,在切断流量之前泵的扬程随包角的增大而减小,0°包角时泵的扬程最大,15°、30°、45°包角时泵的扬程基本相等,60°包角时泵的扬程最小,75°包角时泵的扬程随流量的增大线性减小.叶片包角对泵的效率具有较大影响,泵的效率在任一包角随着流量的增大先增大后减小.在切断流量附近,效率达到最大值;切断流量之前,效率随包角的增大而增大;切断流量之后,包角越大,效率随流量增大而减小得越快.关键词:恒扬程;包角;压水室;切断流量;数值计算中图分类号:TH313文献标志码:AInfluenceofbladewrapangleonperformanceofconstantheadpumpCHENGXiao-rui1,2,TIANLong1,LITian-peng3,YANGDeng-feng4(1.SchoolofEnergyandPowerEngineering,LanzhouUniv.ofTech.,Lanzhou730050,China;2.KeyLaboratoryofFluidMachineryandSystemofGansuProvince,LanzhouUniv.ofTech.,Lanzhou730050,China;3.WuhanHangdaAviationTechnologyDevelopmentCo.Ltd.,Wuhan430010,China;4.CollegeofMechanicsandEngineeringScience,ShanghaiUniv.,Shanghai200072,China)Abstract:Inordertostudytheinfluenceofbladewrapangleontheperformanceofconstantheadpump,siximpellerschemeswithdifferentbladewrapanglehadbeendesigned.BasedontheReynoldstime-aver-ageN-SequationandtheRNGk-εturbulencemodel,thesteadynumericalcalculationhadbeencarriedout,followingthecalculatedresultsverifiedbyexperiments.Theresultsshowthatbeforethecut-offflow,pumpheaddecreaseswiththeincreaseofthewrapangle.Whenthewrapangleofpumpis0degree,thepumpheadisthelargest.Undertheschemesof15degrees,30degrees,and45degrees,theheadofthepumpisalmostequal.Whenthewrapangleofpumpis60degrees,pumphasthesmallesthead,andthepumpheaddecreaseslinearlywiththeincreaseofflowwhenthewrapangleis75degrees.Thebladewrapan...