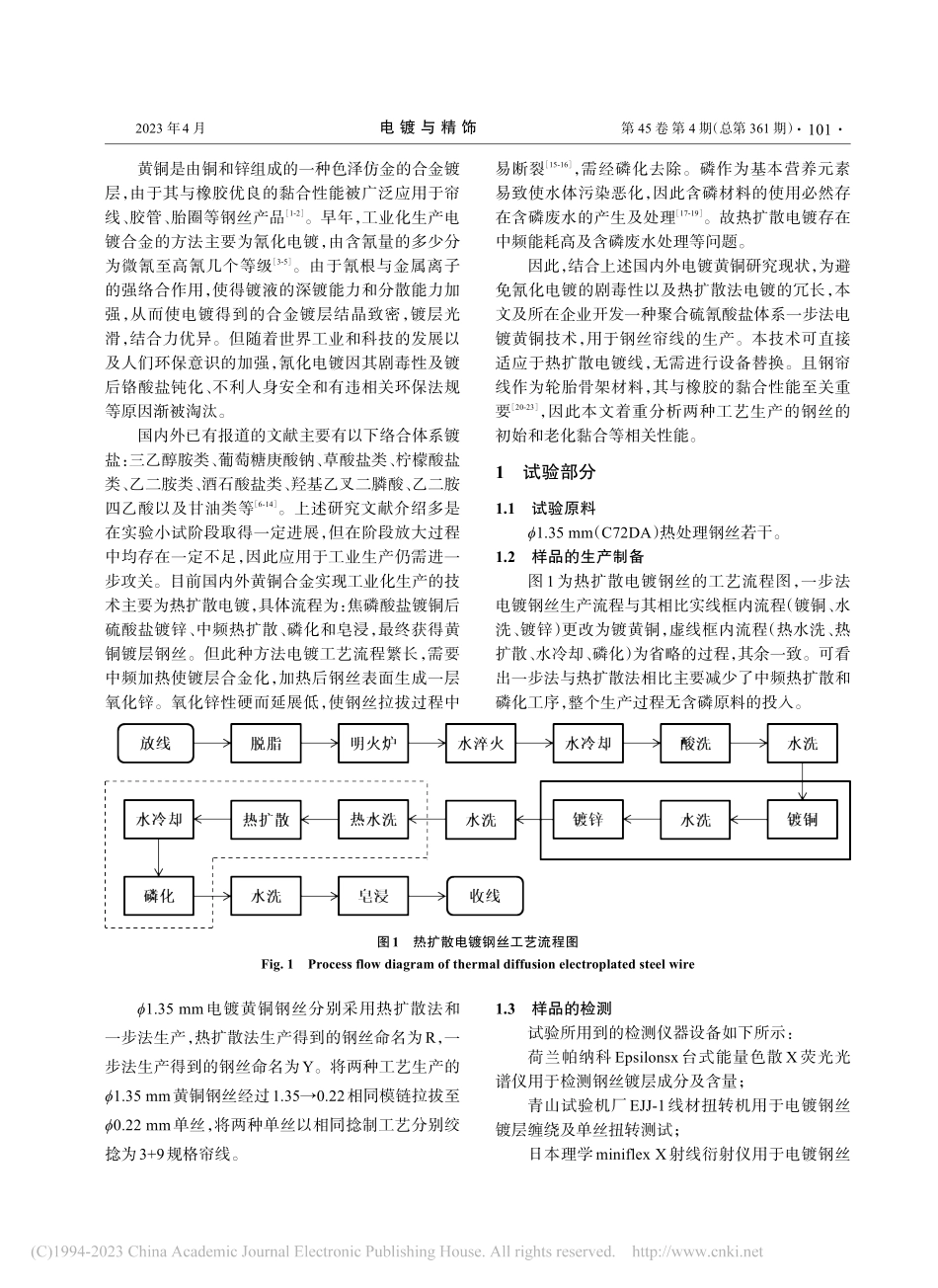

PlatingandFinishingApr.2023Vol.45No.4SerialNo.361一步法替代热扩散电镀工艺对钢帘线性能影响姚利丽1,2*,李呐1,倪自飞1,2,周志嵩1,2,魏于博1(1.江苏兴达钢帘线股份有限公司,江苏泰州225721;2.江苏省结构与功能金属复合材料重点实验室,江苏泰州225721)摘要:钢帘线生产中以一步法电镀工艺代替热扩散电镀,可节约中频热扩散损耗且无需磷化处理,进而减少工艺流程及生产成本。本文对两种工艺3+9结构帘线生产过程的相关性能进行对比分析。研究发现:一步法生产的钢丝镀层更为致密,镀层仅存在α相黄铜,与热扩散电镀的钢丝相比具有更好的延展性,进而使得拉拔过程中的镀层损耗更少,合股过程的断丝率更低,且其镀层内外组分基本均匀一致。一步法钢丝与热扩散钢丝相比具有更低的表面ZnO含量,其初始黏合力高于热扩散帘线约26.15%,3d、7d、14d的93℃/95%RH的湿热老化黏合分别高于热扩散帘线11.49%、17.11%和4.35%,两种工艺帘线初始黏合或老化黏合覆胶率基本一致。关键词:热扩散电镀;一步法电镀;钢帘线;初始黏合;老化黏合中图分类号:TQ153文献标识码:AEffectofone-stepelectroplatinginsteadofthermaldiffusionelectroplatingonpropertiesofsteeltyrecordYaoLili1,2*,LiNa1,NiZifei1,2,ZhouZhisong1,2,WeiYubo1(1.JiangsuXingdaSteelTyreCordCo.,Ltd.,Taizhou225721,China;2.JiangsuKeyLaboratoryforStructuralandFunctionalMetalMaterialsComposites,Taizhou225721,China)Abstract:Intheproductionofsteeltyrecord,one-stepplatingprocessisusedinsteadofthermaldiffu‐sionplating,whichavoidsintermediatefrequencythermaldiffusionconsumptionandphosphating,andthenreducesthetechnologicalprocessandproductioncost.Therelatedpropertiesof3+9steeltyrecordproducedbythetwoprocessesarecompared.Itisfoundthatsteelwirecoatingoftheone-stepprogressisdenser,andmadeofα-phasebrassonly.One-stepsteelwirecoatinghasbetterductility,lesscoatingsheddingduringdrawing,andlowerbreakingfrequencyintwistingthanthermaldiffusionwire.Thecompositionofone-stepsteelwirecoatingisuniform.ThesurfaceZnOcontentofone-stepsteelwireislowerthanthatofthermaldiffusionsteelwire,andtheinitialadhesionisabout26.15%higher.Theag‐ingadhesionforceofone-stepcordat93℃/95%RHconstanttemperatureaging...