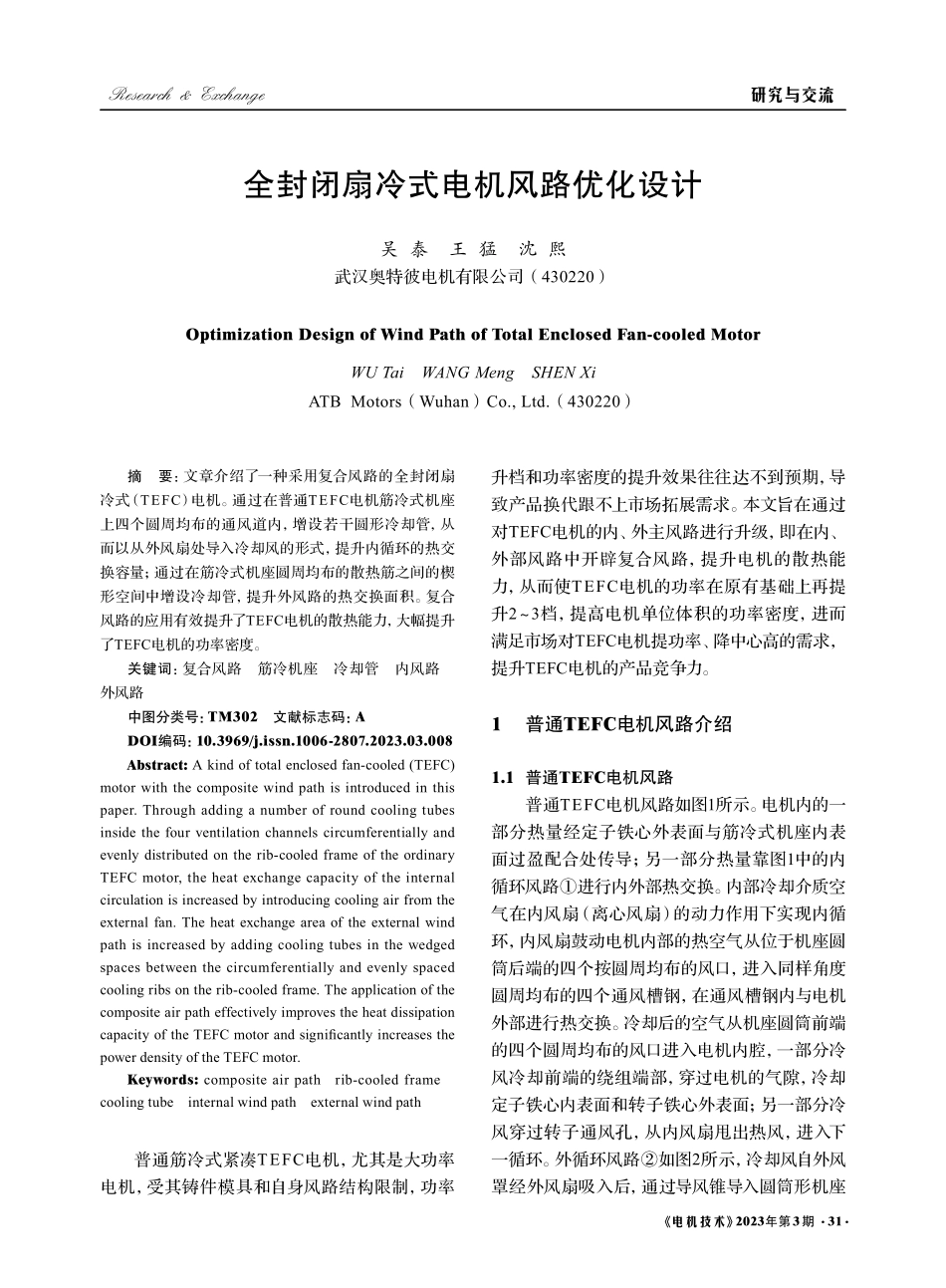

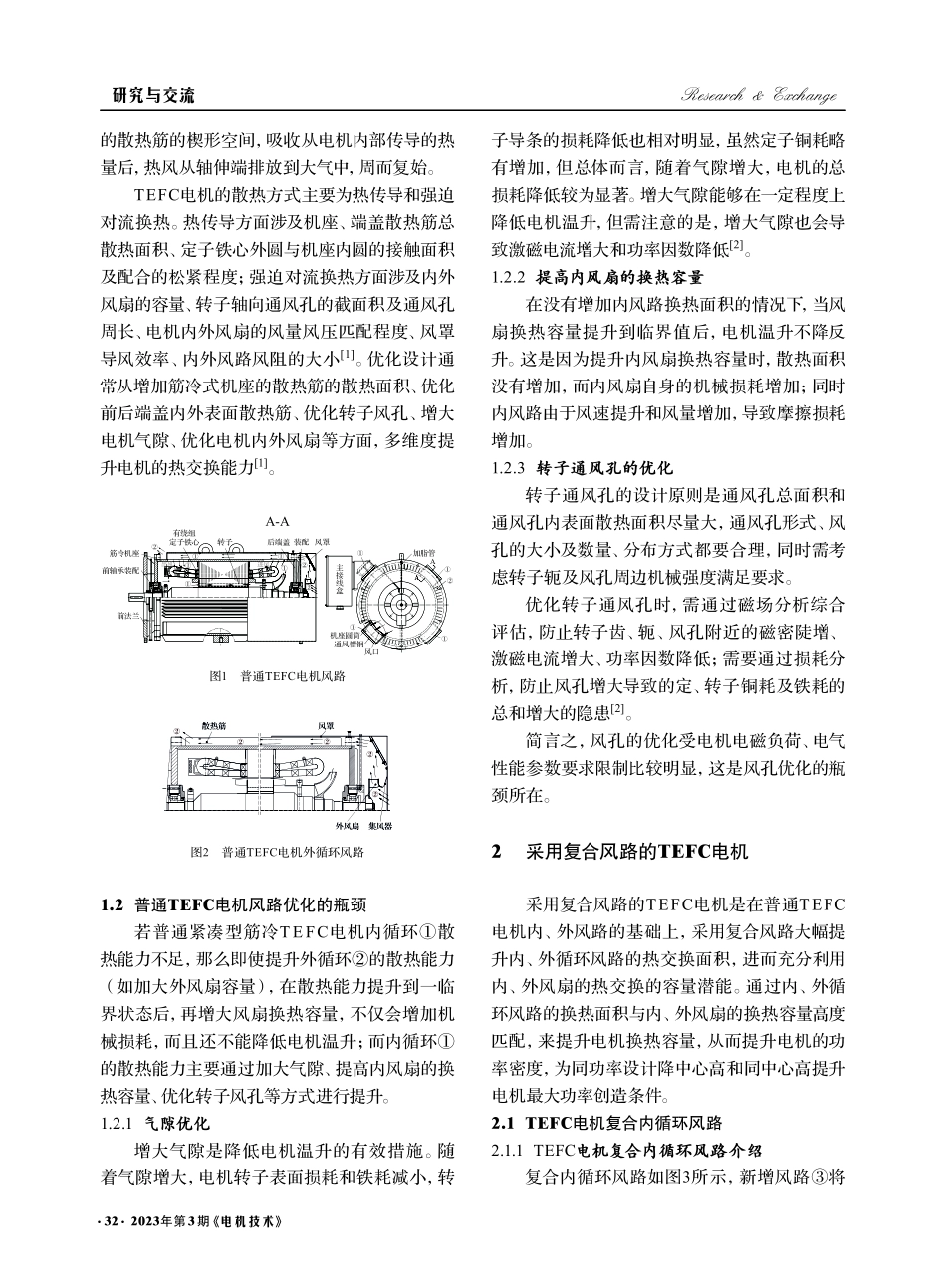

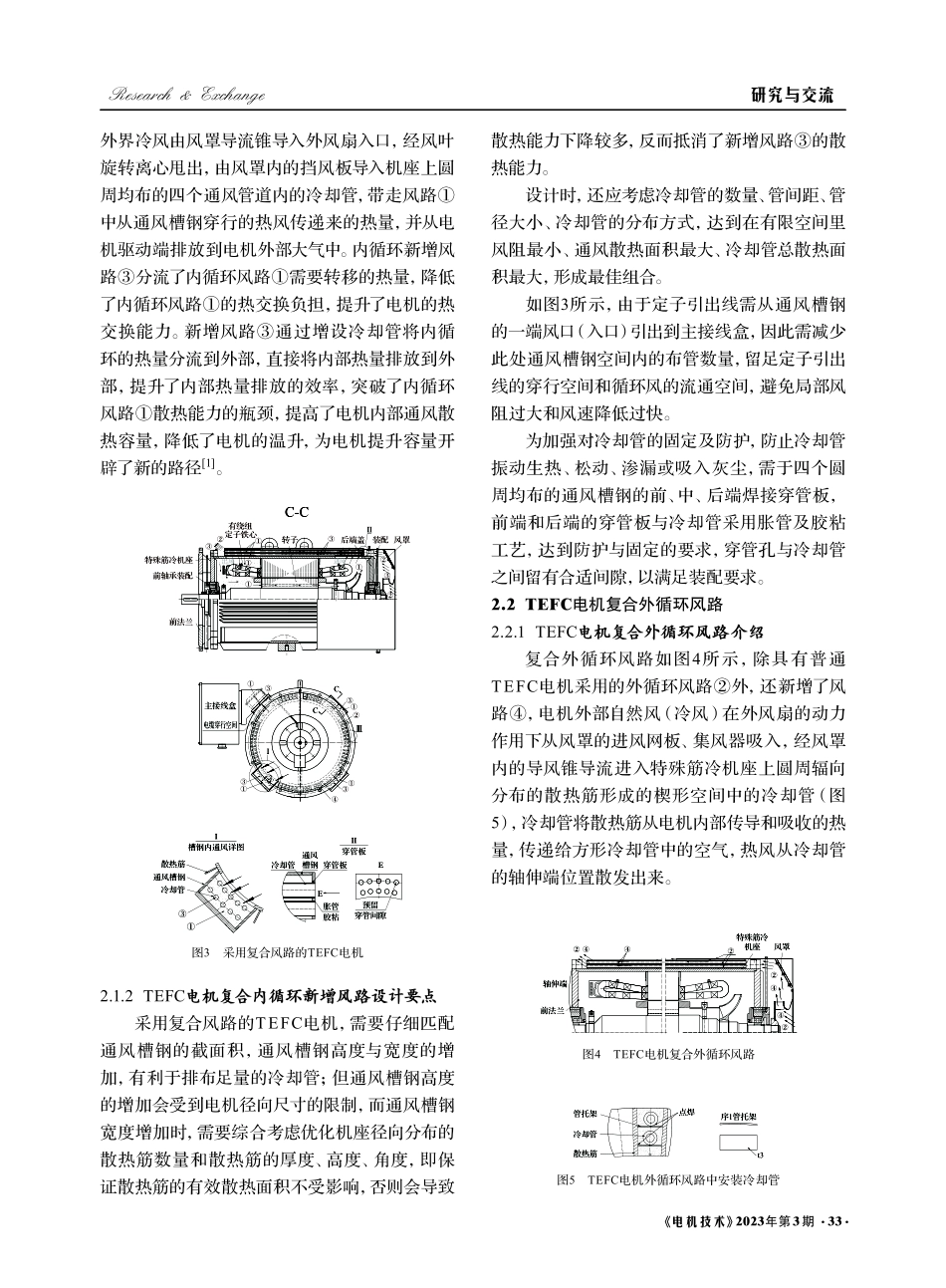

2023年第3期31摘要:文章介绍了一种采用复合风路的全封闭扇冷式(TEFC)电机。通过在普通TEFC电机筋冷式机座上四个圆周均布的通风道内,增设若干圆形冷却管,从而以从外风扇处导入冷却风的形式,提升内循环的热交换容量;通过在筋冷式机座圆周均布的散热筋之间的楔形空间中增设冷却管,提升外风路的热交换面积。复合风路的应用有效提升了TEFC电机的散热能力,大幅提升了TEFC电机的功率密度。关键词:复合风路筋冷机座冷却管内风路外风路中图分类号:TM302文献标志码:ADOI编码:10.3969/j.issn.1006-2807.2023.03.008Abstract:Akindoftotalenclosedfan-cooled(TEFC)motorwiththecompositewindpathisintroducedinthispaper.Throughaddinganumberofroundcoolingtubesinsidethefourventilationchannelscircumferentiallyandevenlydistributedontherib-cooledframeoftheordinaryTEFCmotor,theheatexchangecapacityoftheinternalcirculationisincreasedbyintroducingcoolingairfromtheexternalfan.Theheatexchangeareaoftheexternalwindpathisincreasedbyaddingcoolingtubesinthewedgedspacesbetweenthecircumferentiallyandevenlyspacedcoolingribsontherib-cooledframe.TheapplicationofthecompositeairpatheffectivelyimprovestheheatdissipationcapacityoftheTEFCmotorandsignificantlyincreasesthepowerdensityoftheTEFCmotor.Keywords:compositeairpathrib-cooledframecoolingtubeinternalwindpathexternalwindpath全封闭扇冷式电机风路优化设计吴泰王猛沈熙武汉奥特彼电机有限公司(430220)OptimizationDesignofWindPathofTotalEnclosedFan-cooledMotorWUTaiWANGMengSHENXiATBMotors(Wuhan)Co.,Ltd.(430220)普通筋冷式紧凑TEFC电机,尤其是大功率电机,受其铸件模具和自身风路结构限制,功率升档和功率密度的提升效果往往达不到预期,导致产品换代跟不上市场拓展需求。本文旨在通过对TEFC电机的内、外主风路进行升级,即在内、外部风路中开辟复合风路,提升电机的散热能力,从而使TEFC电机的功率在原有基础上再提升2~3档,提高电机单位体积的功率密度,进而满足市场对TEFC电机提功率、降中心高的需求,提升TEFC电机的产品竞争力。1普通TEFC电机风路介绍1.1普通TEFC电机风路普通TEFC电机风路如图1所示。电机内的一部分热量经定子铁心外表面与筋冷式机座内表面过盈配合处传导;另一部分热量靠图1中的内循环风路①进行内外部热交换。内部冷却...