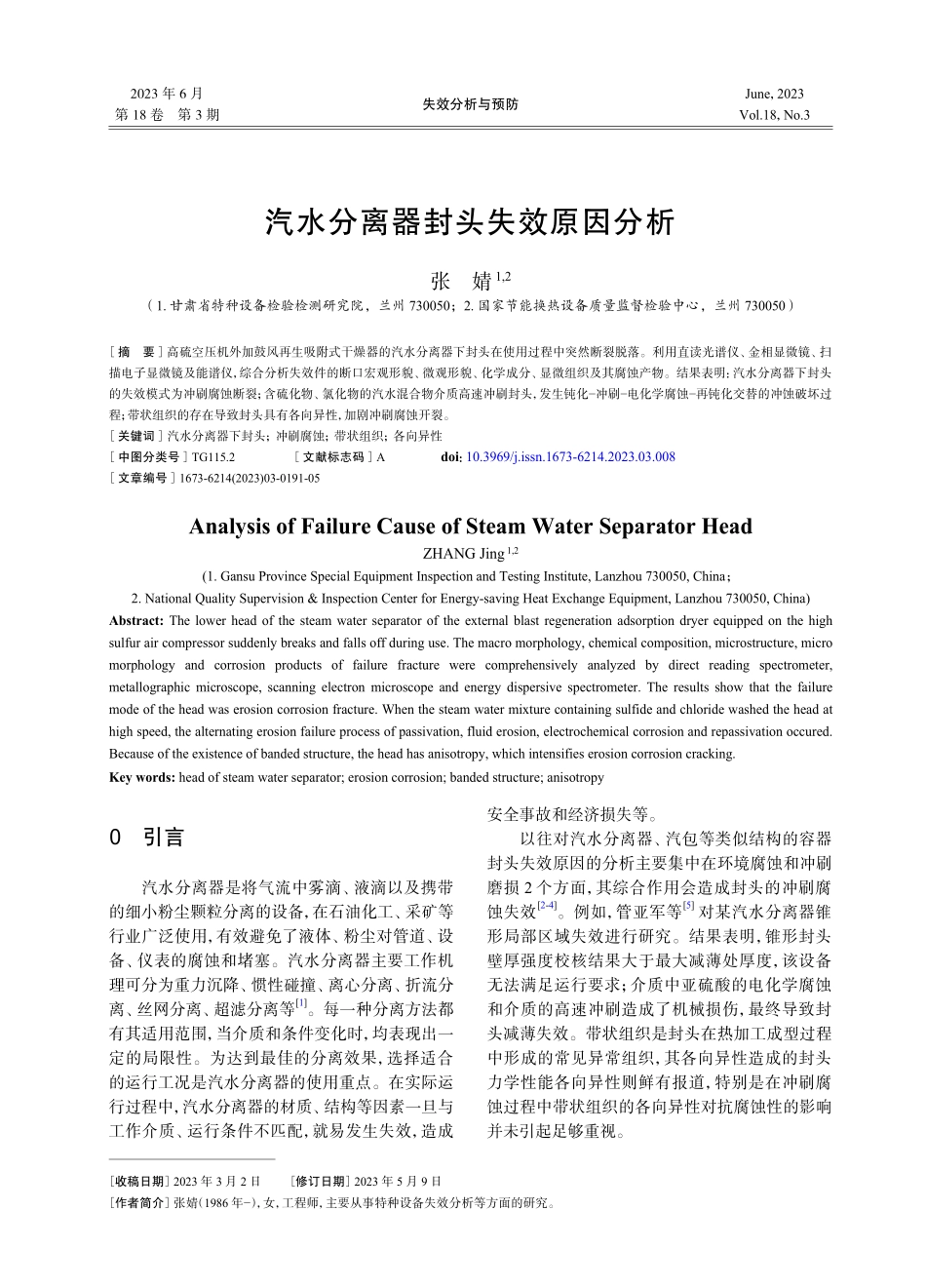

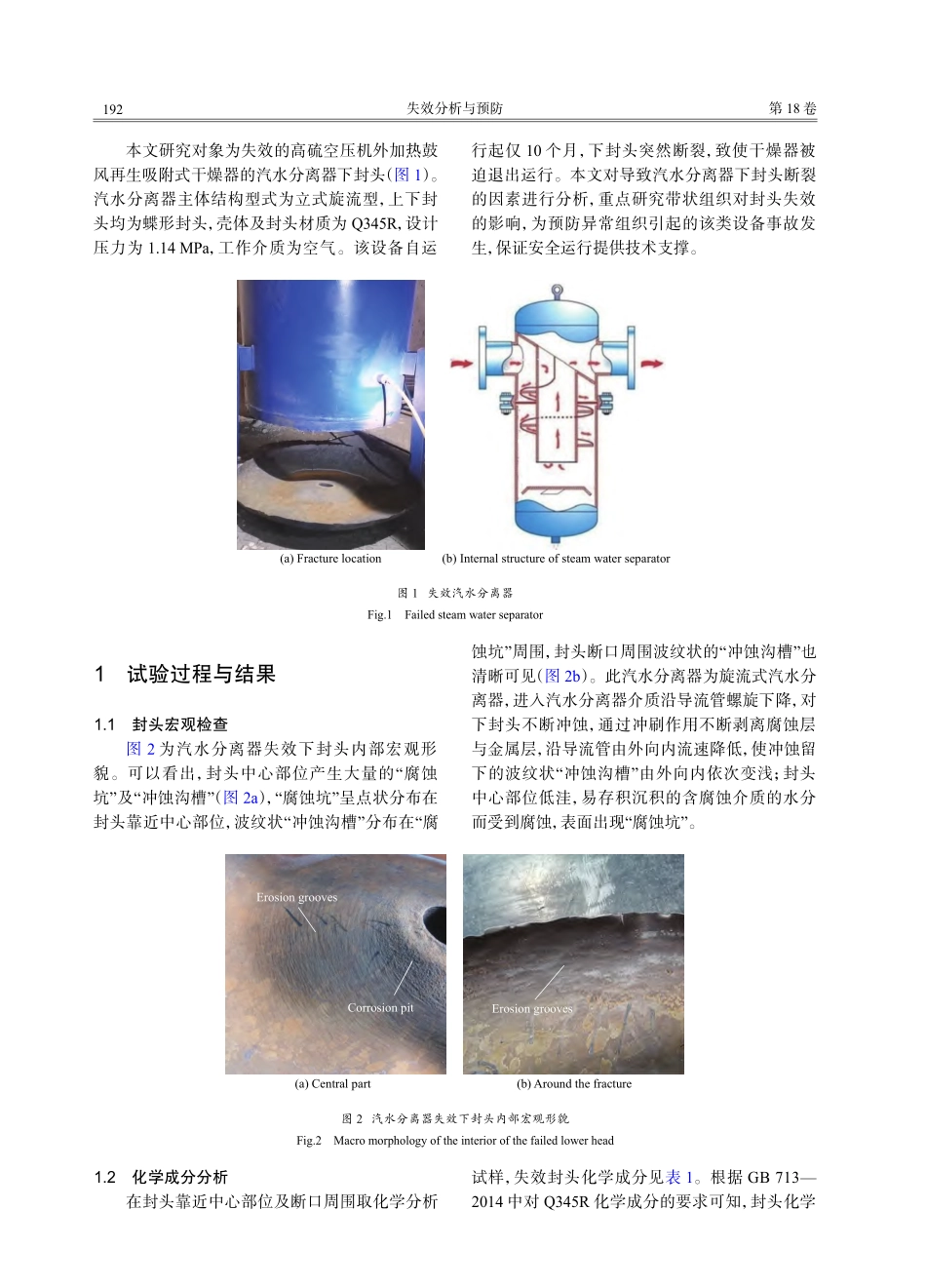

汽水分离器封头失效原因分析张婧1,2(1.甘肃省特种设备检验检测研究院,兰州730050;2.国家节能换热设备质量监督检验中心,兰州730050)[摘要]高硫空压机外加鼓风再生吸附式干燥器的汽水分离器下封头在使用过程中突然断裂脱落。利用直读光谱仪、金相显微镜、扫描电子显微镜及能谱仪,综合分析失效件的断口宏观形貌、微观形貌、化学成分、显微组织及其腐蚀产物。结果表明:汽水分离器下封头的失效模式为冲刷腐蚀断裂;含硫化物、氯化物的汽水混合物介质高速冲刷封头,发生钝化−冲刷−电化学腐蚀−再钝化交替的冲蚀破坏过程;带状组织的存在导致封头具有各向异性,加剧冲刷腐蚀开裂。[关键词]汽水分离器下封头;冲刷腐蚀;带状组织;各向异性[中图分类号]TG115.2[文献标志码]Adoi:10.3969/j.issn.1673-6214.2023.03.008[文章编号]1673-6214(2023)03-0191-05AnalysisofFailureCauseofSteamWaterSeparatorHeadZHANGJing1,2(1.GansuProvinceSpecialEquipmentInspectionandTestingInstitute,Lanzhou730050,China;2.NationalQualitySupervision&InspectionCenterforEnergy-savingHeatExchangeEquipment,Lanzhou730050,China)Abstract:Thelowerheadofthesteamwaterseparatoroftheexternalblastregenerationadsorptiondryerequippedonthehighsulfuraircompressorsuddenlybreaksandfallsoffduringuse.Themacromorphology,chemicalcomposition,microstructure,micromorphologyandcorrosionproductsoffailurefracturewerecomprehensivelyanalyzedbydirectreadingspectrometer,metallographicmicroscope,scanningelectronmicroscopeandenergydispersivespectrometer.Theresultsshowthatthefailuremodeoftheheadwaserosioncorrosionfracture.Whenthesteamwatermixturecontainingsulfideandchloridewashedtheheadathighspeed,thealternatingerosionfailureprocessofpassivation,fluiderosion,electrochemicalcorrosionandrepassivationoccured.Becauseoftheexistenceofbandedstructure,theheadhasanisotropy,whichintensifieserosioncorrosioncracking.Keywords:headofsteamwaterseparator;erosioncorrosion;bandedstructure;anisotropy0引言汽水分离器是将气流中雾滴、液滴以及携带的细小粉尘颗粒分离的设备,在石油化工、采矿等行业广泛使用,有效避免了液体、粉尘对管道、设备、仪表的腐蚀和堵塞。汽水分离器主要工作机理可分为重力沉降、惯性碰撞、离心分离...