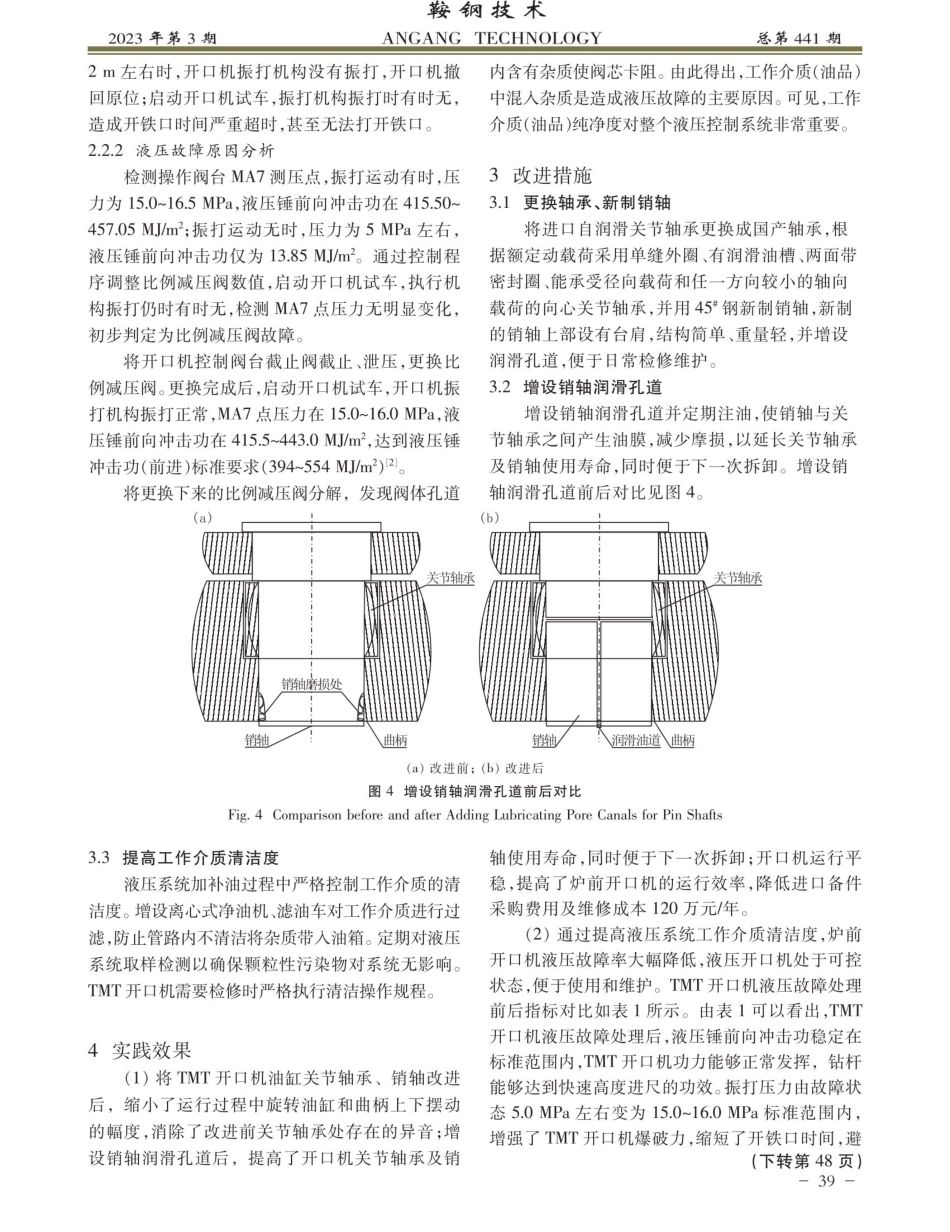

鞍钢技术2023年第3期ANGANGTECHNOLOGY生产实践2850m3高炉TMT开口机故障原因分析及改进措施(本钢板材股份有限公司炼铁总厂,辽宁本溪117021)摘要:针对2580m3高炉炉前TMT开口机常出现的机械故障、液压系统故障,采取了更换轴承、新制销轴、增设销轴润滑孔道和提高工作介质清洁度等改进措施。实践后,旋转油缸和曲柄上下摆动幅度缩小,消除了关节轴承处异音,提高了开口机关节轴承及销轴使用寿命,开口机的平稳运行为高炉稳定顺行提供了保障,降低进口备件采购费用及维修成本120万元/年。关键词:TMT开口机;销轴;关节轴承;比例减压阀中图分类号:TF54D01:10.3969/j.issn.1006-4613.2023.03.008AnalysisonCausesLeadingtoFailureOccurredatTMTTapholeOpeningMachineof2850mBlastFurnaceandImprovementCountermeasuresfortheFailure(GeneralIronmakingPlantofBengangSteelPlatesCo.,Ltd.,Benxi117021,Liaoning,China)Abstract:InallusiontotheproblemthatmechanicalfailuresandhydraulicsystemfailuresoccurredfrequentlyattheTMTtapholeopeningmachineofthe2580mblastfurnacebeforestartingoperations,someimprovementmeasuressuchasreplacingbearings,installingnew-developedpinshafts,addinglubricatingporecanalsforpinshaftsandimprovingthecleanlinessofoperatingmediumweretaken.Afterthesemeasureswereputintopractice,theamplitudeofup-and-downswingingoftherotatedhydrocylinderandthecrankwasdecreased,andalsotheabnormalsoundfromthejointbearingswaseliminated,whiletheservicelifeofthejointbearingsandpinshaftsofthetapholeopeninggearswasprolonged.Sothestableoperationofthetapholeopeningmachineensuredthestableandsmoothoperationoftheblastfurnaceandeventhepurchaseexpensesforimportedsparepartsandmaintenancecostwerereducedby1.2millionyuanRMBperyear.Keywords:TMTtapholeopeningmachine;pinshaft;jointbearing;proportionalpressurereducingvalve开口机是高炉出铁时打开铁口的重要机械设备。鞍钢集团本钢板材股份有限公司炼铁总厂6高炉(2850m²)炉前开铁口设备为德国TMT开口机。近几年,TMT开口机在运行中常出现机械总第441期张廷明文献标识码:A文章编号:1006-4613(2023)03-0037-03ZHANGTingming故障、液压控制系统故障,对炉前渣铁排放产生了不良影响。为了保证高炉的稳定顺行,分析了故障产生的原因,并采取...