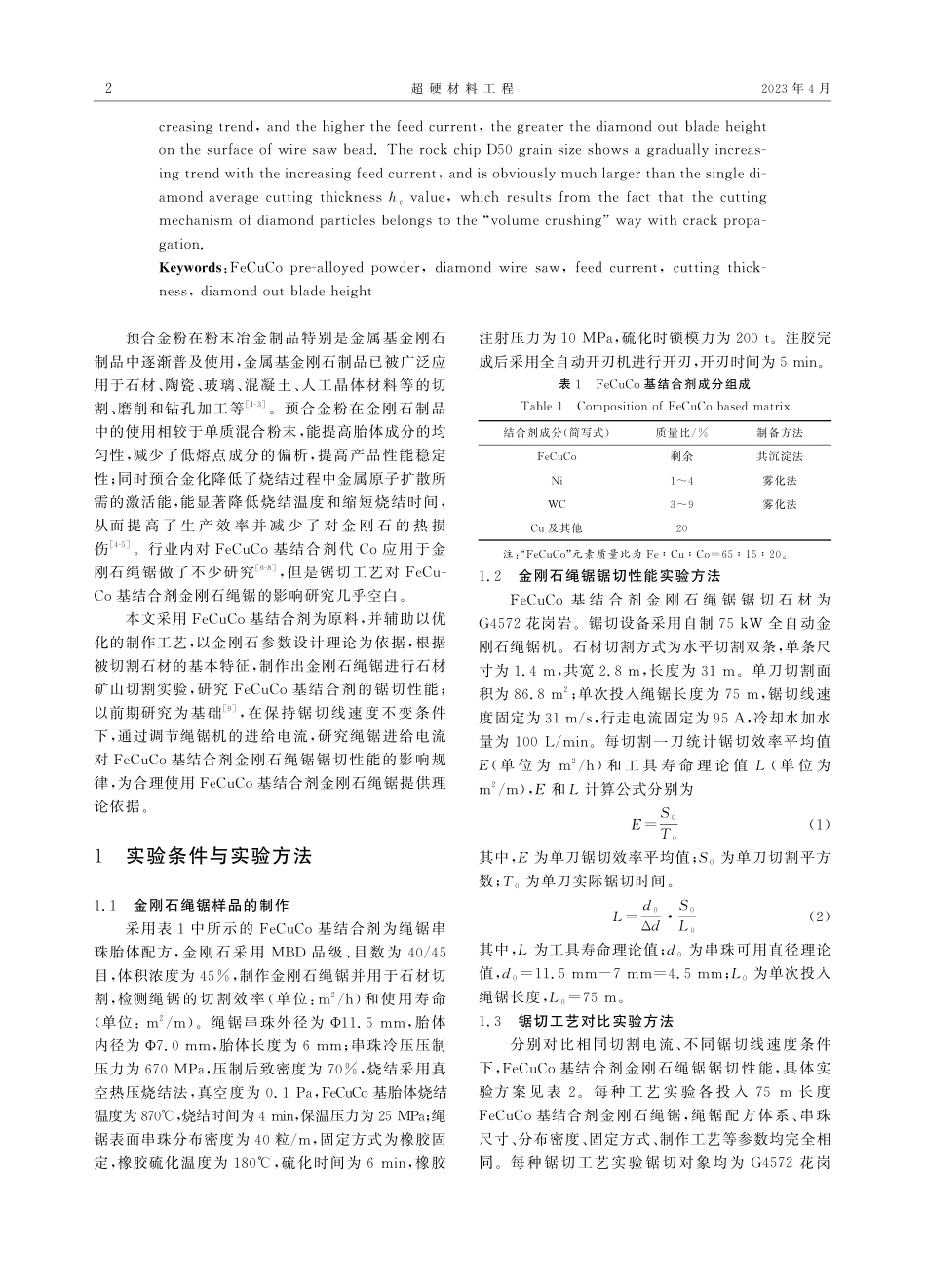

第35卷第2期超硬材料工程Vol.352023年4月SUPERHARDMATERIALENGINEERINGApr.,2023进给电流对FeCuCo基结合剂金刚石绳锯性能影响刘志环1,2,于盛睿1,廖才超2,娄晶2,陈浚阳2,翟振鑫2(1.景德镇陶瓷大学机械电子工程学院,江西景德镇333403;2.江西众利超硬材料工具有限公司,江西上饶333100)摘要:采用FeCuCo基结合剂为原料和优化的制作工艺,以金刚石参数设计理论为依据,根据被切割石材的基本特征,制作出金刚石绳锯并进行石材矿山切割实验,研究绳锯进给电流I对FeCuCo基结合剂金刚石绳锯锯切性能的影响规律。结果表明:在不同进给电流时,随着锯切的进行和串珠直径的逐渐消耗,绳锯锯切效率逐渐提高,而工具理论寿命逐渐降低;随着进给电流的增加,绳锯串珠表面单颗金刚石平均切削厚度hc值呈逐渐增加的趋势,表面完整态金刚石出刃高度平均值也呈逐渐增加的趋势,且进给电流越大,串珠表面金刚石出刃高度越大;随着进给电流的提高,岩屑D50粒度也呈现逐渐增大的趋势,且明显远大于单颗金刚石平均切削厚度hc值,这是由于金刚石颗粒的切削机理属于有裂纹扩展的“体积破碎”方式产生的。关键词:FeCuCo;金刚石绳锯;进给电流;切削厚度;出刃高度中图分类号:TQ164文献标识码:A文章编号:1673-1433(2023)02-0001-07InfluenceoffeedcurrentontheperformanceofFeCuCobaseddiamondwiresawLIUZhihuan1,2,YUShengrui1,LIAOCaichao2,LOUJing2,CHENJunyang2,ZHAIZhenxin2(1.SchoolofMechanicalandElectronicEngineering,JingdezhenCeramicUniversity,Jingdezhen333403,China;2.JiangxiZhongliSuperhardMaterialToolsCo.,Ltd.,Shangrao333100,China)Abstract:FeCuCobasedmatrixandtheoptimizedfabricationprocessareused,basedonthetheoryofdiamondparameterdesign,accordingtothebasiccharacteristicsofthestonebeingcut,adiamondwiresawismanufacturedforstonecuttingexperimentinthemine.TheeffectofwiresawfeedcurrentIonthecuttingperformanceofFeCuCobaseddia-mondwiresawisstudied.Thestudyresultshowsthatatdifferentfeedcurrent,asthesawingprogressedandthebeaddiameterisgraduallyconsumed,thesawingefficiencyofwiresawgraduallyincreases,andthetheoreticallifeofthetoolgraduallydecreases.Withtheincreaseoffeedcurrent,hcvalueofaveragecuttingthicknessofsinglediamondonthesurfaceofwiresawbeadshowsagraduallyincreasingtrend.Theaveragevalueofdia-mondoutbladeheightonth...