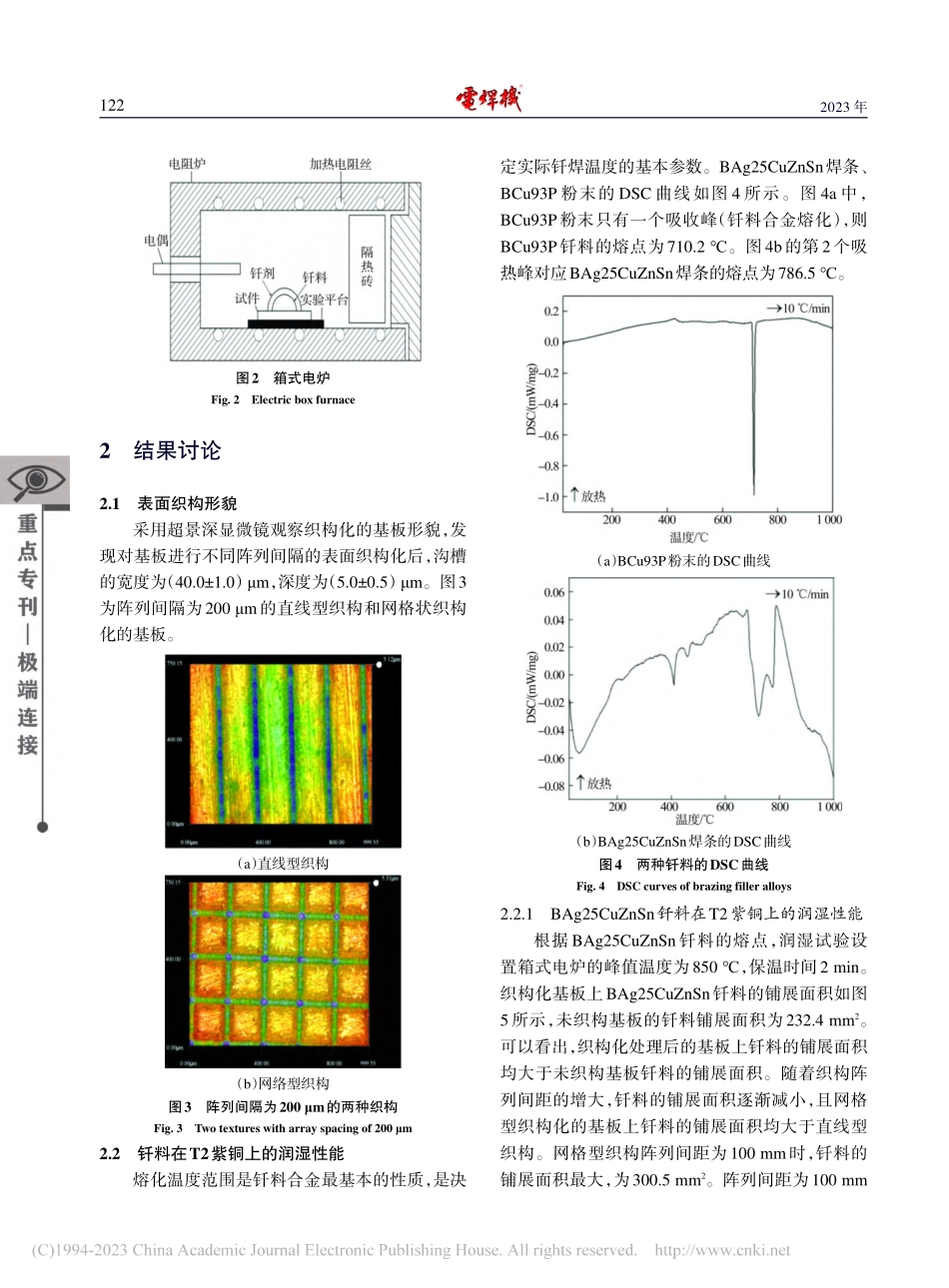

ElectricWeldingMachineVol.53No.4Apr.2023第53卷第4期2023年4月表面织构化对铜基钎料润湿流铺的影响研究杨洋1,2,周俞廷1,2,赵亦嘉1,21.中国机械科学研究总院集团有限公司,北京1000442.中国机械总院集团宁波智能机床研究院有限公司,浙江宁波315700摘要:为改善钎料在基板表面的润湿性能,采用激光加工技术在T2紫铜基板表面加工了两类不同阵列间距的直线型织构和网格型织构,探究表面织构对钎料润湿性能的影响。以BAg25CuZnSn焊条、BCu93P-A粉末为钎料,在T2紫铜表面进行润湿性试验,探讨表面织构类型及织构间距对钎料在T2紫铜基板上润湿性的影响。试验结果表明:对T2紫铜基板表面织构化,钎料铺展面积增大,钎料为BCu93P-A、网格型织构阵列间距为100μm时,铺展面积最大为322.4mm2;随着织构阵列间距的减小,两种钎料的铺展面积均逐渐增大,且直线型织构化的基板润湿性能小于网格型织构化的基板。关键词:激光加工技术;表面织构;润湿性;铺展面积中图分类号:TG425文献标识码:A文章编号:1001-2303(2023)04-0120-06StudyontheEffectofSurfaceTextureontheWettingFlowofCopper-BasedBrazingFillerYANGYang1,2,ZHOUYuting1,2,ZHAOYijia1,21.ChinaAcademyofMachineryScienceandTechnologyGroup,Beijing100044,China2.ChinaAcademyofMachineryNingboAcademyofIntelligentMachineToolCo.,Ltd.,Ningbo315700,ChinaAbstract:Toimprovethewettabilityofsolderonthesubstratesurface,T2copperwasselectedasthesubstrateandtwotypesoflineargroovesandreticulatedgrooveswithdifferentarrayspacingwerepreparedonthesurfaceofthecopperusingtheHG100-20Wlasermarkingmachine.WettabilitytestswerecarriedoutontheT2coppersurfaceusingBAg25CuZnSnelectrodesandBCu93P-Apowderasthebrazingmaterial,andtheeffectofthesurfacefabricandthespacingofthefabriconthewettabilityofthebrazingmaterialontheT2coppersubstratewasinvestigated.TheexperimentalresultsshowthatthesurfacetextureoftheT2coppersubstrateincreasesthespreadingareaofthesolder.WhenthesolderisBCu93P-Aandthegroovetexturearrayspacingis100μm,themaximumspreadingareais322.4mm2.Withthedecreaseofthetexturearrayspacing,thespreadingareaofthetwosoldersgraduallyincreases,andthewettabilityofthelineartexturedsubstrateissmallerthanthatofthegridtexturedsubstrate....