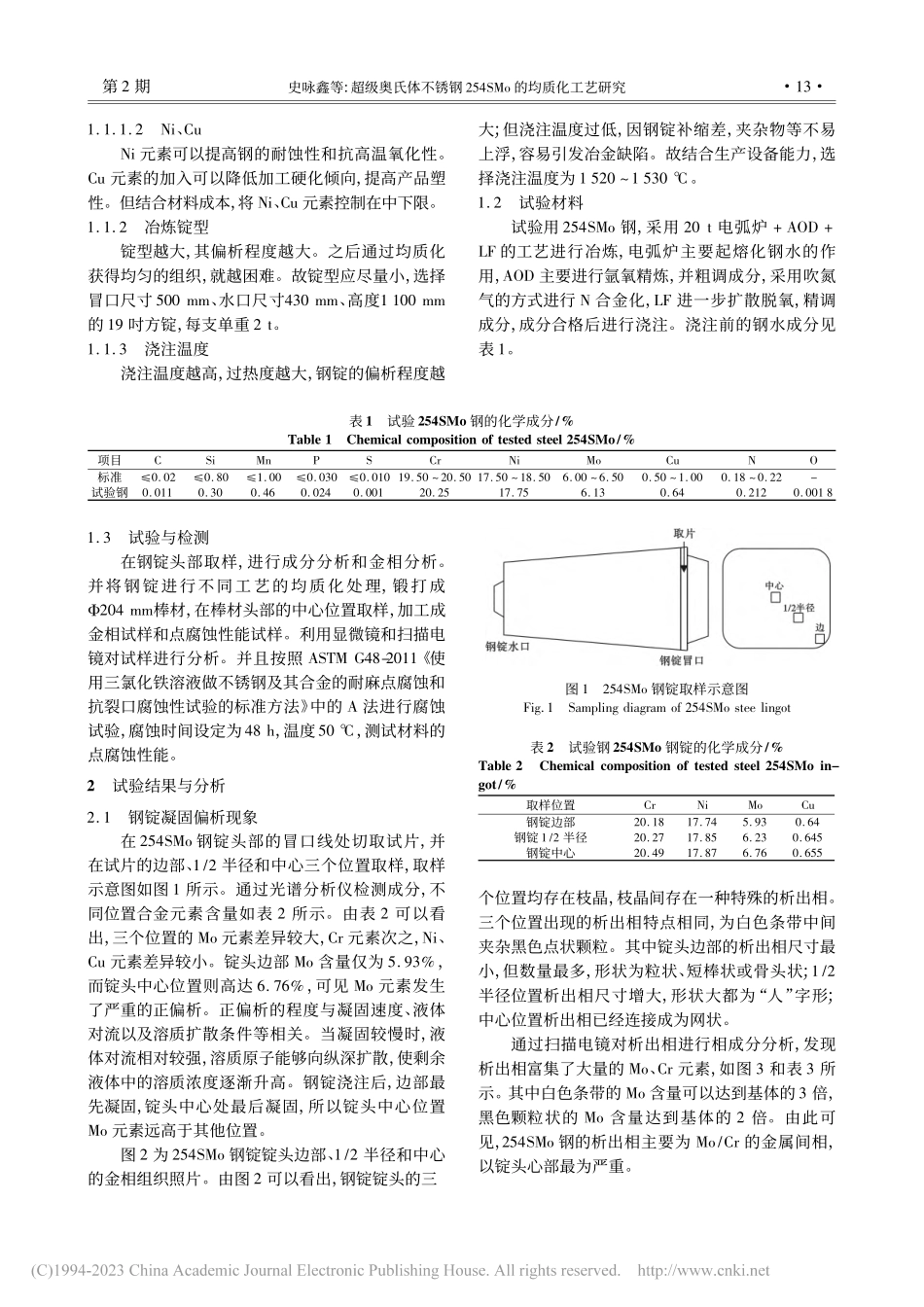

作者简介:史咏鑫(1989-),男,工程师;硕士;E-mail:shiyongxin198902@126.com;收稿日期:2022-08-19DOI:10.20057/j.1003-8620.2022-00094超级奥氏体不锈钢254SMo的均质化工艺研究史咏鑫1,2,李青1,2,钟庆元1,2,田伟1,2,叶强1,2(1中航上大高温合金材料股份有限公司,邢台054800;2河北省特种合金再生工程技术研究中心,邢台054800)摘要:试验用超级奥氏体不锈钢254SMo(/%:0.011C,0.30Si,0.46Mn,20.25Cr,17.75Ni,6.13Mo,0.64Cu,0.212N)采用20t电弧炉+AOD+LF精炼的工艺冶炼,研究了254SMo钢的铸态组织,发现枝晶间存在大量的析出相,其临近冒口钢锭头部中心的析出相尺寸最大,且呈网状分布。钢锭经1240℃8~40h均质化处理后,锻造成Φ204mm棒材,检验其析出相数量和点腐蚀速率。试验结果表明:随着均质化时间的延长,其析出相尺寸减小,数量减少,钢的点腐蚀性能提高;均质化12h+镦粗拔长+均质化12h为最优均质化工艺。关键词:超级奥氏体不锈钢254SMo;析出相;点腐蚀速率;均质化StudyonHomogenizationProcessofSuperAusteniticStainlessSteel254SMoShiYongxin1,2,LiQing1,2,ZhongQingyuan1,2,TianWei1,2,YeQiang1,2(1AvicShangdaSuperalloysCompanyLimited,Xingtai054800;2HebeiEngineeringResearchCenterforSpecialAlloyRegeneration,Xingtai054800)Abstract:Thetestedsuperausteniticstainlesssteel254SMo(/%:0.011C,0.30Si,0.46Mn,20.25Cr,17.75Ni,6.13Mo,0.64Cu,0.212N)ismeltedby20telectricarcfurnace+AOD+LFrefining,theas-castmicrostructureof254SMOsteelhasbeenstudied.Itisfoundthattherearealargenumberofprecipitatesbetweendendrites,andtheprecipi-tatesinthecenterofingotheadnearhottoparethelargestanddistributedinanetwork.Afterhomogenizationtreatmentat1240℃for8-40h,theingotsareforgedtoΦ204mmbar,thequantityofprecipitatedphaseandpittingcorrosionrateareinspected.Theexperimentalresultsshowthatwiththeprolongationofhomogenizationtime,thesizeandquantityofprecipi-tatesdecrease,andthepittingcorrosionperformanceofsteelimproves;Homogenizationfor12h+UpsettingandStretching+homogenizationfor12histheoptimalhomogenizationprocess.KeyWords:SuperAusteniticStainlessSteel254SMo;PrecipitatedPhase;PittingCorrosionRate;Homogenization超级奥...