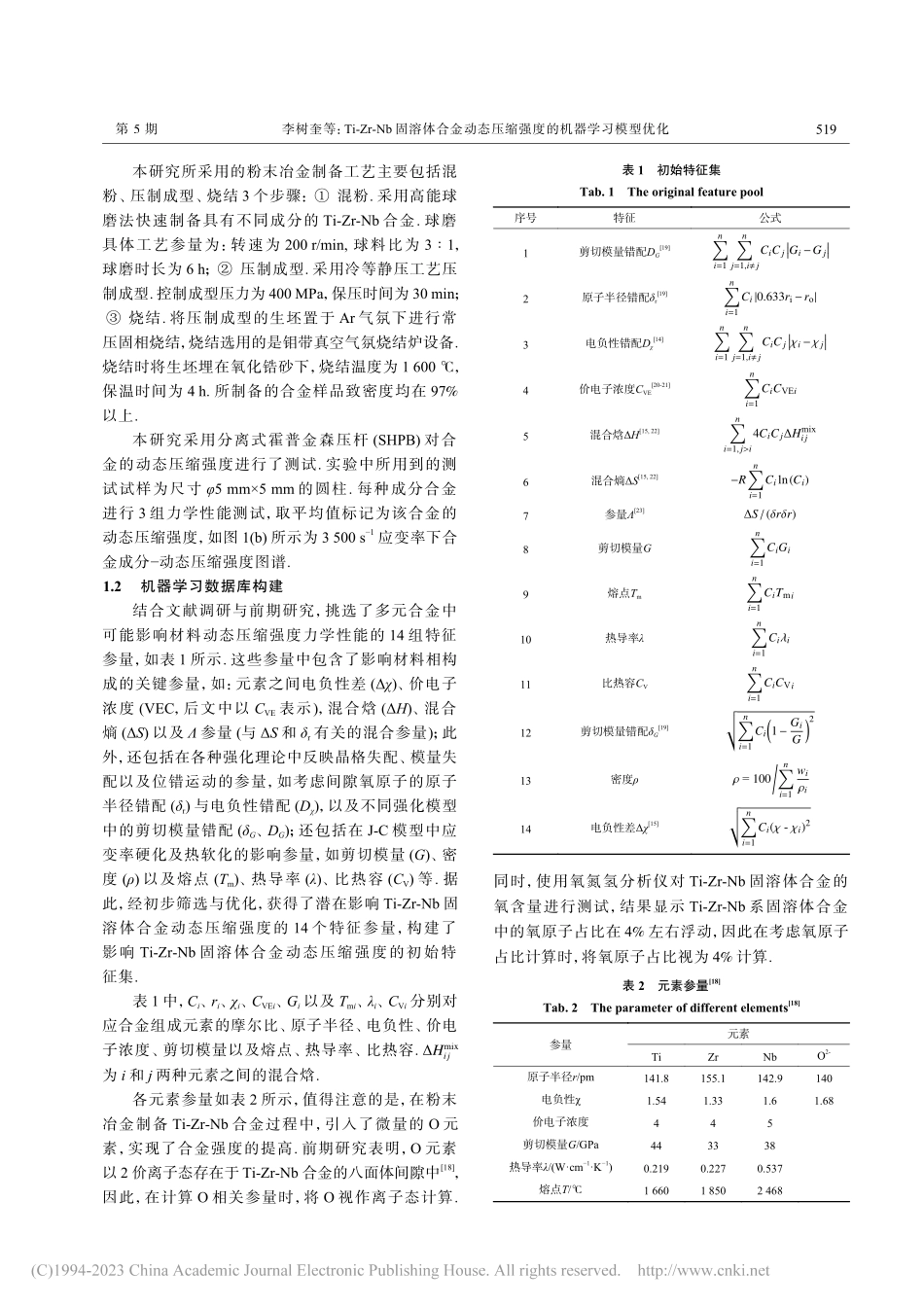

Ti-Zr-Nb固溶体合金动态压缩强度的机器学习模型优化李树奎1,2,樊博建1,刘兴伟1,司胜平1,刘爽1,谢如玥1,刘金旭1,3(1.北京理工大学材料学院,北京100081;2.深圳北理莫斯科大学材料系,广东,深圳518172;3.北京理工大学冲击环境材料技术国家级重点实验室,北京100081)摘要:Ti-Zr-Nb固溶体合金具有优异的强塑性匹配和撞击释能活性,在杀爆战斗部毁伤元和聚能战斗部药型罩材料领域极具应用价值.为了实现Ti-Zr-Nb合金及类似固溶体合金的动态力学性能精准预测,并支撑战斗部材料的精准设计与成分优化,采用粉末冶金法制备了56种Ti-Zr-Nb合金,并测试了材料的动态压缩强度,在此基础上开展了Ti-Zr-Nb合金动态压缩强度预测的机器学习模型优化、主控参量筛选研究,优化后的模型实现了合金动态压缩强度的预测误差<8%,并揭示了影响合金动态压缩强度的3个关键主控参量及权重排序:Δχ>G>δG.采用优化后的模型成功设计了具有更高动态压缩强度的合金成分,经试验验证,所设计的材料动态压缩强度达到3100MPa,高于同类固溶体合金.关键词:Ti-Zr-Nb固溶体合金;动态压缩强度;机器学习中图分类号:TG146.2文献标志码:A文章编号:1001-0645(2023)05-0517-09DOI:10.15918/j.tbit1001-0645.2022.112StudyontheMachineLearningModelOptimizationBasedonDynamicCompressionStrengthofTi-Zr-NbSolidSolutionAlloysLIShukui1,2,FANBojian1,LIUXingwei1,SIShengping1,LIUShuang1,XIERuyue1,LIUJinxu1,3(1.SchoolofMaterialsScienceandEngineering,BeijingInstituteofTechnology,Beijing100081,China;2.SchoolofMaterialsScienceandEngineering,ShenzhenMSU-BITUniversity,Shenzhen,Guangdong518172,China;3.NationalKeyLaboratoryofScienceandTechnologyonMaterialsUnderShockandImpact,BeijingInstituteofTechnology,Beijing100081,China)Abstract:TheTi-Zr-Nbsolidsolutionalloyspossessgreatapplicationvalueinthefieldsofblastandfragmenta-tionwarheadandshapedwarheadduetoitsexcellentstrength,plasticityandimpactenergyreleasecharacterist-ics.InordertoachieveaccuratepredictionofdynamicmechanicalpropertiesofTi-Zr-Nbsolidsolutionalloysandprovidesupporttocompositionoptimizationofwarheadmaterials,56Ti-Zr-Nballoyswerepreparedbypowdermetallurgyandthedynamiccompressionstrengthwastested.Furthermore,optimizationofmachine...