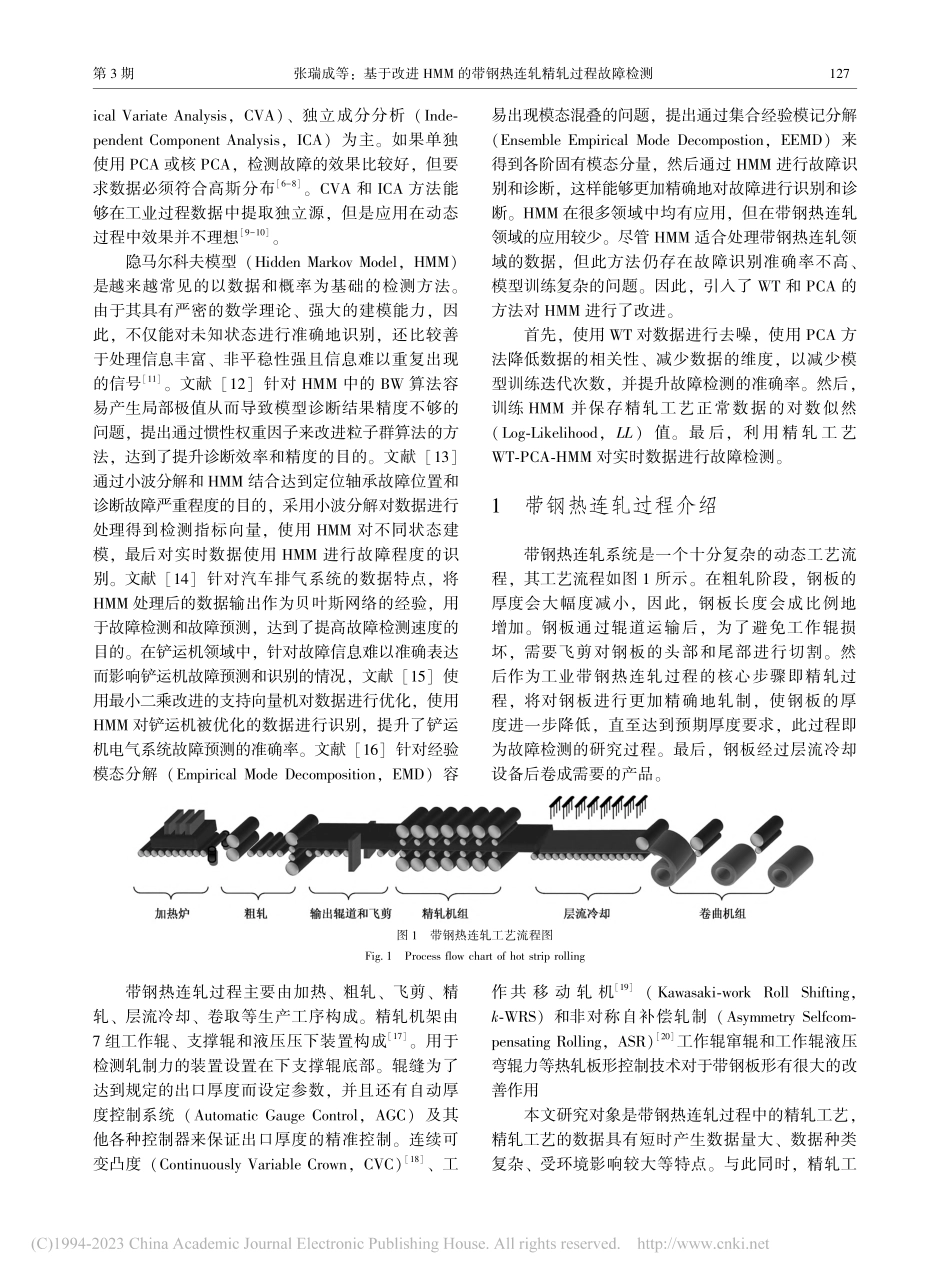

第48卷第3期Vol.48No.3FORGING&STAMPINGTECHNOLOGY2023年3月Mar.2023■■■■■■■■■■■■轧制基于改进HMM的带钢热连轧精轧过程故障检测张瑞成,崔凯鑫,梁卫征(华北理工大学电气工程学院,河北唐山063210)摘要:针对传统HMM方法故障检测的准确率不高,以及带钢热连轧过程数据的非线性和混合高斯性问题,提出一种利用WT和PCA改进HMM的故障检测新方法。首先,采用小波变换对轧制数据进行去噪处理,并使用PCA将数据的维度降低、数据相关性减小,可以有效减少模型训练的迭代次数,并且能够提升故障检测的准确率;然后,利用期望最大化算法结合观测序列训练得到WT-PCA-HMM故障检测模型;最后,通过模型得出精轧工艺数据的对数似然值即可实现故障检测。结果表明:与传统HMM方法相比,WT-PCA-HMM的故障检测方法不仅能够降低8.1%的误报率,而且减少50%的模型训练迭代次数,为故障的检测提供了新方法。关键词:带钢;热连轧;故障检测;小波变换;主成分分析;隐马尔科夫模型DOI:10.13330/j.issn.1000-3940.2023.03.017中图分类号:TP273文献标志码:A文章编号:1000-3940(2023)03-0126-06FaultdetectionoffinishrollingprocessforhotstriprollingbasedonimprovedHMMZhangRuicheng,CuiKaixin,LiangWeizheng(CollegeofElectricalEngineering,NorthChinaUniversityofScienceandTechnology,Tangshan063210,China)Abstract:AnewmethodoffaultdetectionwasproposedtoimprovetheHMMbasedonWTandPCAtosolvetheproblemsoflowaccuracyofthetraditionalHMMmethodandthenonlinearityandmixedGaussianityofthehotstriprollingprocessdata.Firstly,wavelettransformwasusedtodenoisetherollingdata,andPCAwasusedtoreducethedimensionalityandcorrelationofthedata,whichcaneffectivelyreducethenumberofiterationsformodeltrainingandimprovetheaccuracyoffaultdetection.Then,theWT-PCA-HMMfaultdetectionmodelwasob-tainedbyusingtheexpectationmaximizationalgorithmcombinedwiththetrainingofobservedsequencetraining.Finally,thelogarithmiclikelihoodvaluesofthefinishingprocessdatawasderivedfromthemodeltoachievethefaultdetection.TheresultsshowthattheWT-PCA-HMMfaultdetectionmethodcannotonlyreducethefalsealarmrateby8.1%comparedwiththetraditionalHMMmethod,butalsoreducethenumberofmodeltrainingiterationsby50%,whichprovidesanewmethodforthefaultdetection.Keywords:s...