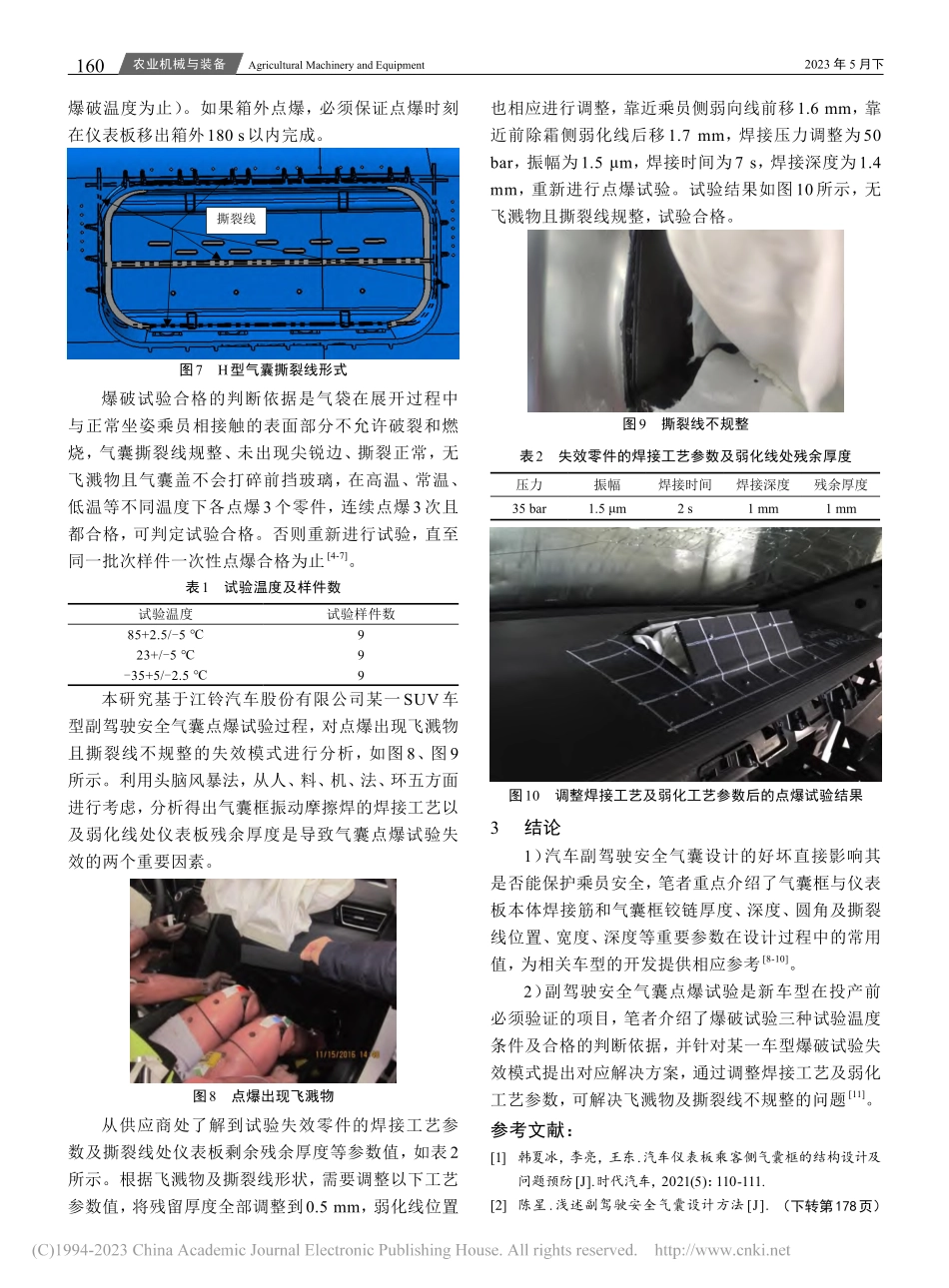

1582023年5月下AgriculturalMachineryandEquipment农业机械与装备副驾驶安全气囊设计要点及爆破试验失效模式史秀丽(江西五十铃汽车有限公司,江西南昌330001)摘要:副驾驶安全气囊设计的好坏决定了其是否能正常打开并保护乘员安全。笔者分析了H型撕裂线副驾驶安全气囊的设计要点,包括气囊框焊接筋的焊接深度及布置距离、V型铰链的厚度、圆角半径及深度等相关参数,同时阐述了H型副驾驶安全气囊撕裂线的形式及撕裂线位置如何定义,并介绍了安全气囊在高温、常温以及低温条件下的爆破试验,试验合格判断依据以及爆破时常见的失效模式。通过飞溅物及撕裂线形状确定调整焊接工艺及弱化线处仪表板剩余残余厚度,可确保安全气囊试验结果满足规范要求,为后续车型副驾驶安全气囊的设计开发提供相应参考。关键词:副驾驶安全气囊;撕裂线;铰链;爆破试验中图分类号:U463文献标志码:ADOI:10.3969/j.issn.1672-3872.2023.10.047KeyPointsofPassengerAirbagDesignandFailureModesonDeploymentTestShiXiuli(JiangxiIsuzuMotorsCo.,Ltd.,JiangxiNanchang330001)Abstract:Thedesignofthepassengerairbagdetermineswhetheritcanbeopenednormallyandprotectthesafetyofpassengers.TheauthoranalyzesthekeypointsofthedesignofthepassengerairbagoftheHtypetearline,includingtheweldingdepthandarrangementdistanceoftheweldingribsoftheairbagframe,thethicknessoftheVtypehinge,theradiusanddepthofthefillet,andotherrelevantparameters.Atthesametime,theauthorexpoundstheformofthetearlineoftheHtypepassengerairbagandhowtodefinethepositionofthetearline,andintroducestheexplosiontestsoftheairbagunderhightemperature,normaltemperature,andlowtemperatureconditions,thejudgmentbasisforthetestqualificationandthecommonfailuremodesduringblasting.Theweldingprocessandtheresidualthicknessoftheinstrumentpanelattheweakeninglinearedeterminedandadjustedbytheshapeofthespatterandtearline,whichcanensurethatthetestresultsoftheairbagmeetthespecificationrequirements,andprovidecorrespondingreferenceforthedesignanddevelopmentofthepassengerairbagofthefollowingmodels.Keywords:passengerairbag;tearline;hinge;deploymenttest汽车安全分为主动安全和被动安全,汽车副驾驶安全气囊属于汽车被动安全系统的重要零部件,其安装在副...