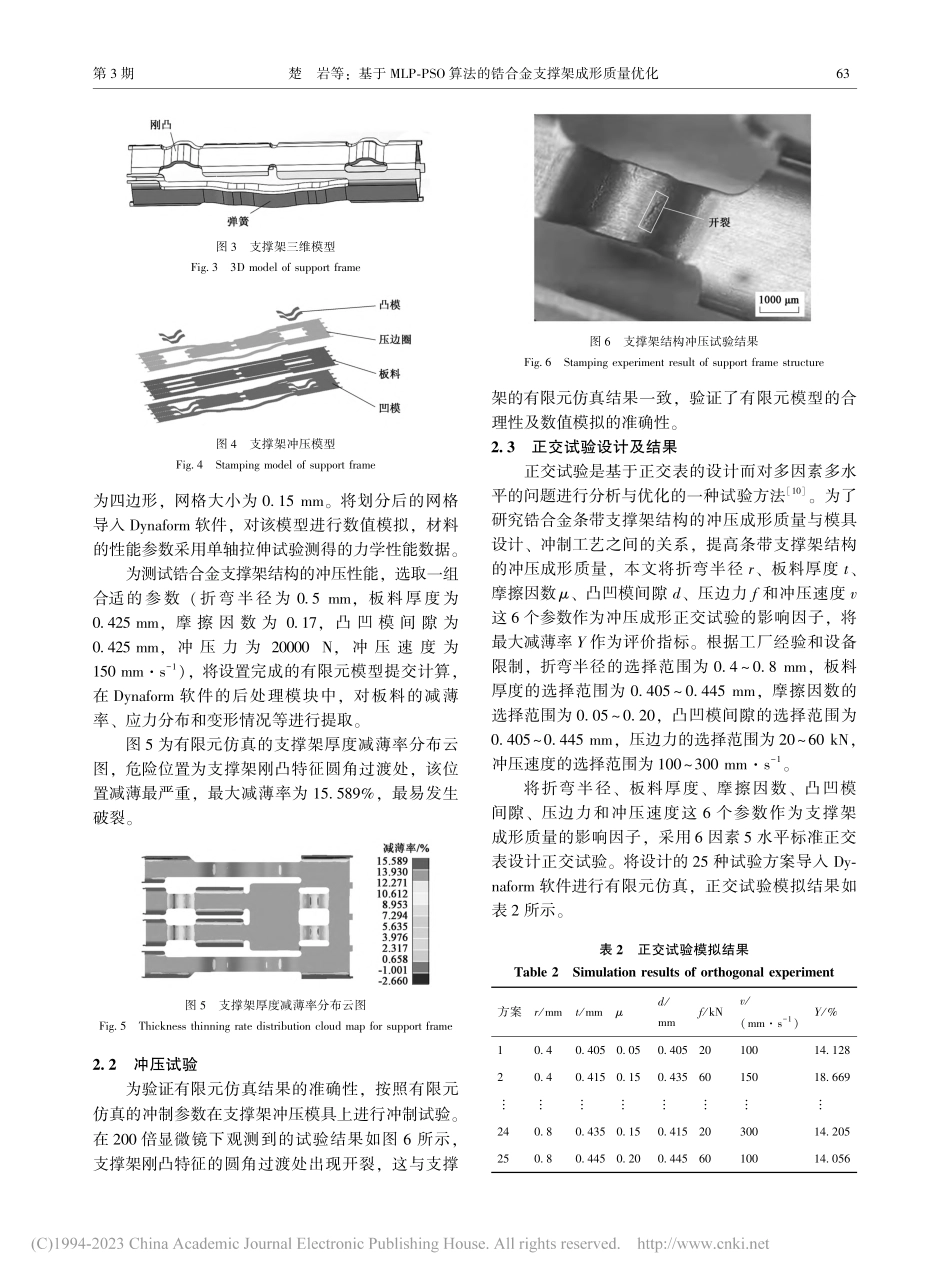

第48卷第3期Vol.48No.3FORGING&STAMPINGTECHNOLOGY2023年3月Mar.2023基于MLP-PSO算法的锆合金支撑架成形质量优化楚岩1,毛建中1,张小民1,袁佳健2(1.湖南大学机械与运载工程学院,湖南长沙410082;2.湖南交通职业技术学院机电工程学院,湖南长沙410132)摘要:为了提高锆合金支撑架的冲压成形质量,基于Dynaform软件和正交试验设计方法,将最大减薄率作为评价指标,研究了折弯半径、板料厚度、摩擦因数、凸凹模间隙、压边力和冲压速度等参数对支撑架成形质量的影响规律。通过数值模拟获得了样本数据,利用多层感知机神经网络训练出预测支撑架减薄率的模型,对各因素的相关性进行分析,并通过粒子群优化算法得到了最优参数方案。结果表明:多层感知机神经网络模型能够有效预测支撑架的减薄率。在影响支撑架冲压的各参数中,折弯半径和摩擦因数的影响较大,凸凹模间隙和冲压速度的影响较小。采用粒子群算法优化后的参数方案进行冲压成形,最大减薄率降低24.2%,可有效降低支撑架的破裂率,提高支撑架的冲压成形质量。关键词:锆合金;支撑架;冲压成形;减薄率;多层感知机;粒子群优化算法DOI:10.13330/j.issn.1000-3940.2023.03.008中图分类号:TG386文献标志码:A文章编号:1000-3940(2023)03-0061-07OptimizationonformingqualityforzirconiumalloysupportframebasedonMLP-PSOalgorithmChuYan1,MaoJianzhong1,ZhangXiaomin1,YuanJiajian2(1.CollegeofMechanicalandVehicleEngineering,HunanUniversity,Changsha410082,China;2.CollegeofMechanicalandElectricalEngineering,HunanCommunicationEngineeringPolytechnic,Changsha410132,China)Abstract:Inordertoimprovethestampingqualityofzirconiumalloysupportframe,basedonDynaformsoftwareandorthogonalexperi-mentaldesignmethod,takingthemaximumthinningrateastheevaluationindex,theinfluencelawsofparameterssuchasbendingradi-us,sheetthickness,frictionfactor,clearancebetweenpunchanddie,blankholderforceandstampingspeedontheformingqualityofsupportframewereinvestigated.Then,thesampledatawasobtainedbynumericalsimulation,andthemodelforpredictingthethinningrateofsupportframewastrainedbyusingthemulti-layerperceptronneuralnetwork.Furthermore,thecorrelationofeachfactorwasanalyzed,andtheoptimalparameterschemewasobtainedbytheparticleswarmoptimizationalgorithm.Theresultsshowthatthemul...