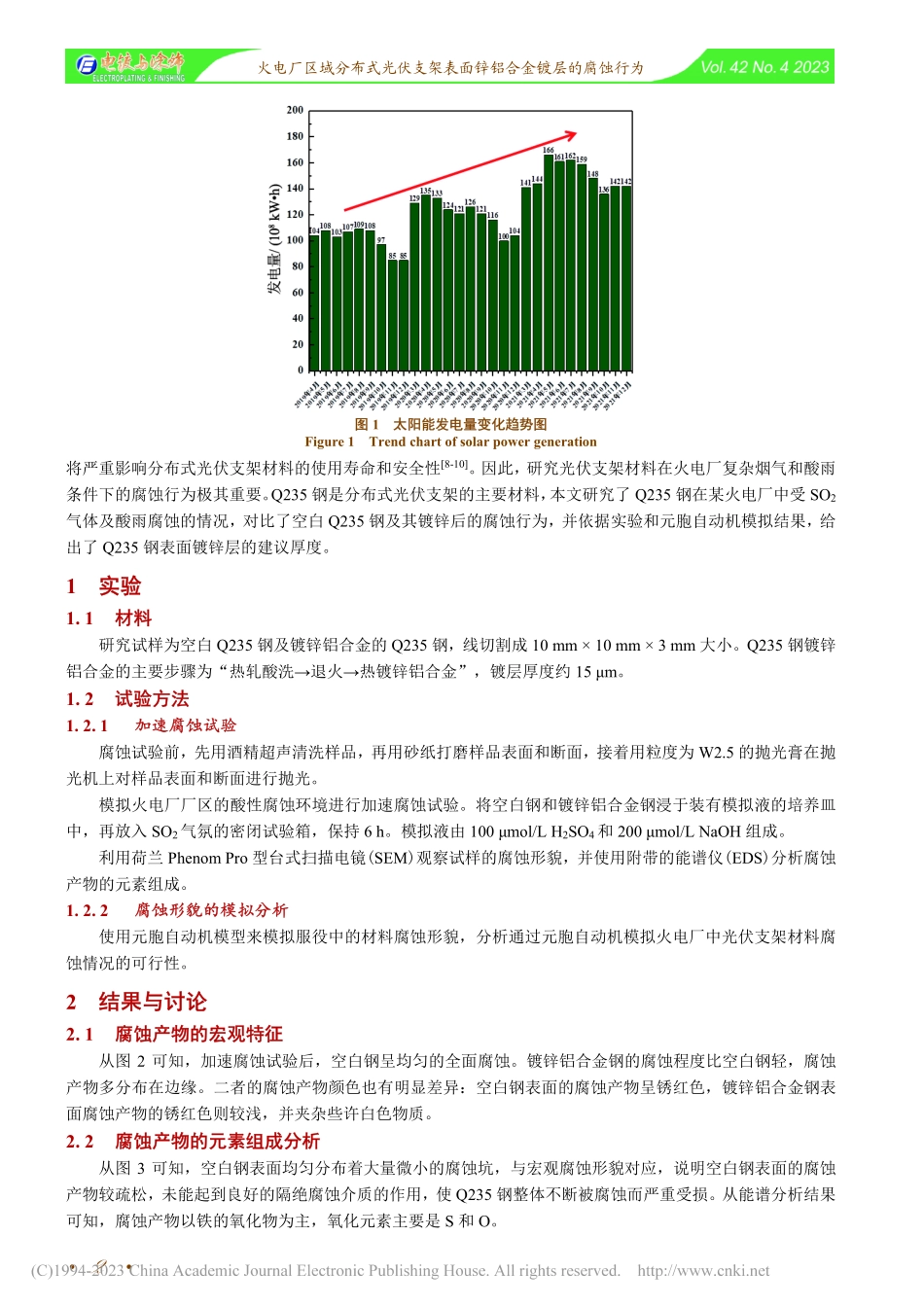

•1•【防腐技术/AnticorrosionTechnology】DOI:10.19289/j.1004-227x.2023.04.001火电厂区域分布式光伏支架表面锌铝合金镀层的腐蚀行为李广一1,朱涛1,杨欢红2,*,刘新超1,朱伟星1,杨小玲11.上海奉贤燃机发电有限公司,上海2014492.上海电力大学电气工程学院,上海200090摘要:通过加速腐蚀试验模拟了空白Q235钢及热浸镀锌铝合金钢在火电厂酸性腐蚀环境中的腐蚀行为,通过扫描电镜和能谱仪对比了它们的腐蚀形貌和腐蚀产物组成。结果发现,锌铝合金镀层能够有效提高Q235钢的耐蚀性,因Zn和Al氧化腐蚀形成的双层致密膜层共同构成了保护Q235基体的两道防线。基于元胞自动机原理,通过Matlab软件模拟了Q235钢表面锌铝合金镀层的截面腐蚀形貌,并与在火电厂中服役的镀锌铝合金钢的实际情况进行对比,确定了镀锌铝合金钢的腐蚀规律。模拟计算了不同厚度镀锌层的腐蚀情况,再结合热浸镀工艺和光伏支架材料的现实情况,建议表面镀锌铝合金层的平均厚度至少为30μm,这样才能保证光伏支架的安全性和服役寿命。关键词:碳钢;热浸镀;锌铝合金;火电厂;腐蚀;模拟中图分类号:TQ153.2;TG178文献标志码:A文章编号:1004–227X(2023)04–0001–05Corrosionbehaviorofhot-dipZn–AlalloycoatingondistributedphotovoltaicbracketinthermalpowerplantLIGuangyi1,ZHUTao1,YANGHuanhong2,*,LIUXinchao1,ZHUWeixing1,YANGXiaoling11.ShanghaiFengxianGasTurbinePowerGenerationCo.,Ltd.,Shanghai201499,China2.CollegeofElectricalEngineering,ShanghaiUniversityofElectricPower,Shanghai200090,ChinaAbstract:ThecorrosionbehaviorofQ235steelwithandwithoutahot-dipZn–Alalloycoatinginacidiccorrosionenvironmentofthermalpowerplantwassimulatedbyacceleratedcorrosiontest.Theircorrosionmorphologiesandcomponentsofcorrosionproductwerecomparedbasedonthescanningelectronmicroscopicobservationandenergy-dispersivespectroscopicanalysis.ItwasfoundthatthecorrosionresistanceofQ235steelcouldbeeffectivelyimprovedbyhot-dipcoatingwithaZn–Alalloylayer,duetotheformationofacompactdouble-layeredfilmcomprisingtheoxidesofZnandAlofferingtwodefenselinestoprotecttheQ235substrate.ThecorrosionmorphologyofZn–AlalloycoatingonQ235steelsubstratewassimulatedbyMatlabsoftwarebasedontheprincipleofcellularautomataandcomparedwiththeac...