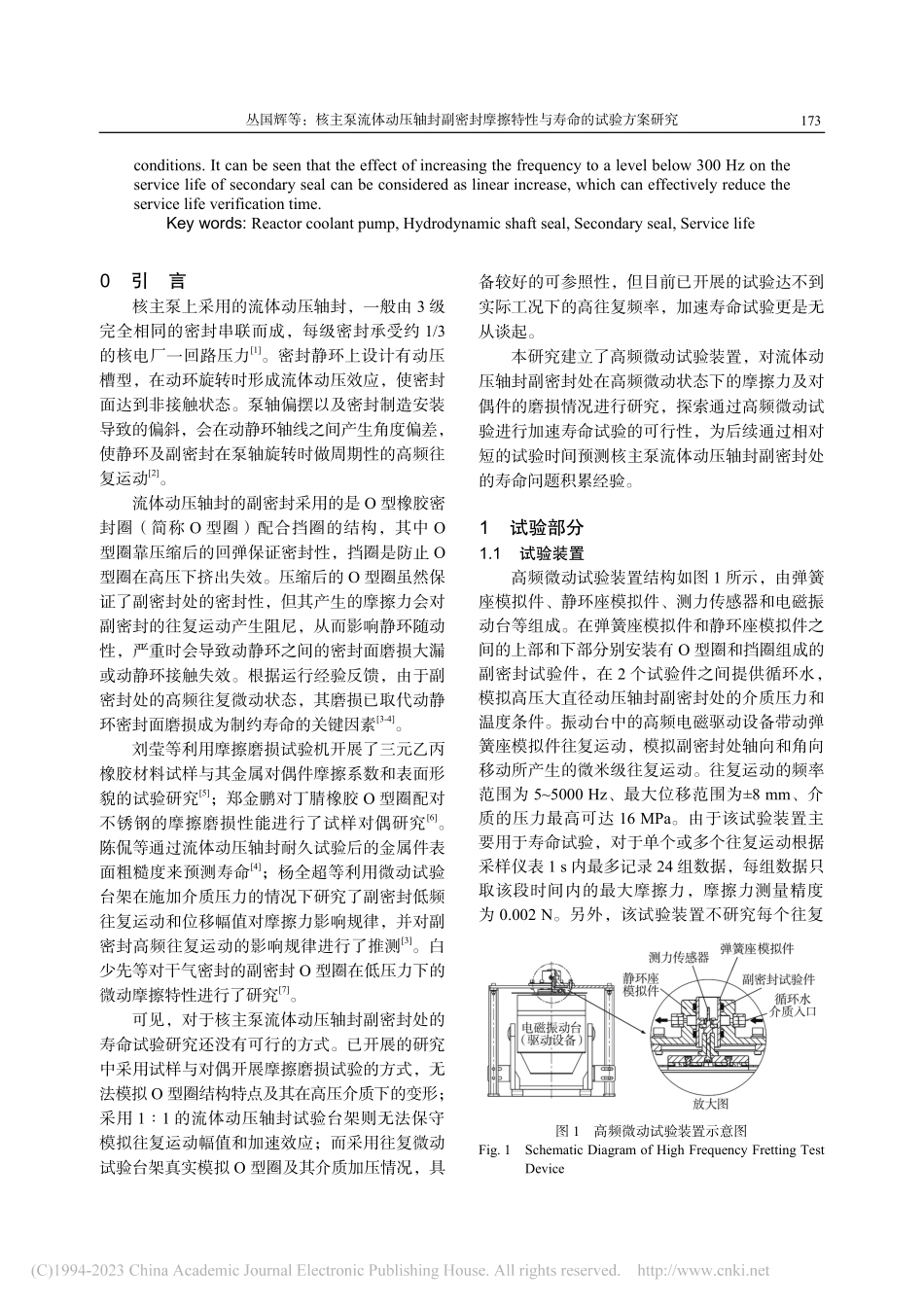

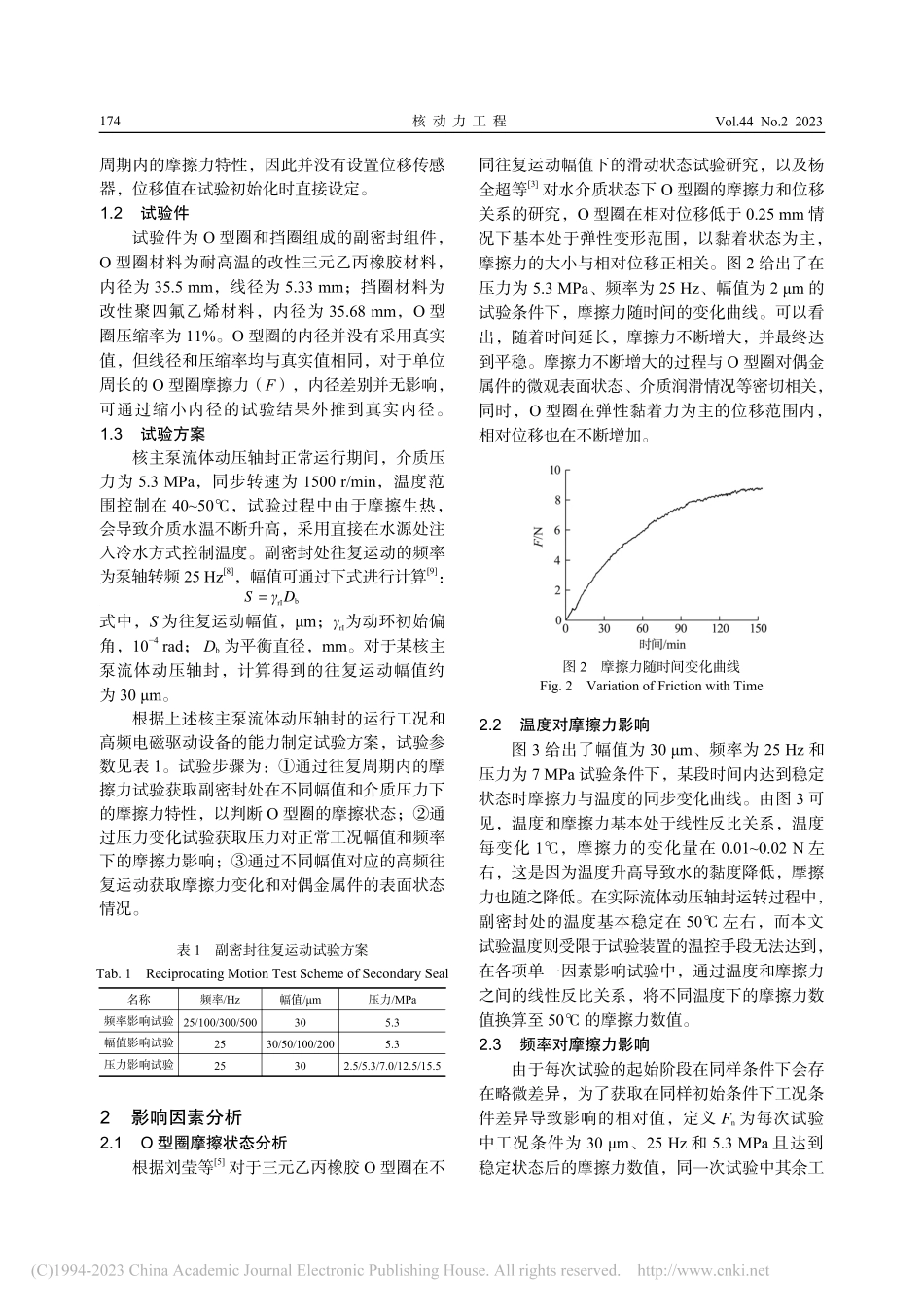

文章编号:0258-0926(2023)02-0172-05;DOI:10.13832/j.jnpe.2023.02.0172核主泵流体动压轴封副密封摩擦特性与寿命的试验方案研究丛国辉,张翊勋,段远刚中广核工程有限公司核电安全监控技术与装备国家重点实验室,广东深圳,518124摘要:副密封处的摩擦性能与寿命是影响核主泵流体动压轴封寿命的关键因素,为了研究副密封处的长期运行寿命,建立了高频往复试验装置,以模拟副密封处在高压介质条件下的往复运动,获取了副密封处O型橡胶密封圈与对偶金属件在频率提高、位移幅值增加和介质压力提高3种工况下的摩擦力变化数据,结果表明:核主泵流体动压轴封副密封在正常运行工况频率为25Hz、幅值约为30μm及介质压力为5.3MPa时处于微动弹变状态;基于正常运行工况提高频率,在不超过300Hz时副密封处的摩擦特性基本不会改变,但超过500Hz时摩擦特性会明显变化;基于正常运行工况增加幅值和提高介质压力,副密封处的摩擦特性也基本维持不变。可见,在300Hz以下提高频率对副密封寿命的影响可按线性增加考虑,能有效降低寿命验证时间。关键词:核主泵;流体动压轴封;副密封;寿命中图分类号:TL334文献标志码:AStudyonTestSchemeforFrictionPropertiesandServiceLifeofSecondarySealofReactorCoolantPumpHydrodynamicShaftSealCongGuohui,ZhangYixun,DuanYuangangStateKeyLaboratoryofNuclearPowerSafetyMonitoringTechnologyandEquipment,ChinaNuclearPowerEngineeringCo.,Ltd.,Shenzhen,Guangdong,518124,ChinaAbstract:Thefrictionpropertiesandservicelifeofthesecondarysealarethekeyfactorsaffectingtheservicelifeofthehydrodynamicshaftsealofthereactorcoolantpump.Inordertostudythelong-termservicelifeofthesecondaryseal,ahigh-frequencyreciprocatingtestdeviceisestablishedtosimulatethereciprocatingmotionofthesecondarysealunderthehighpressuremediumcondition,andthefrictionchangedataoftheO-shapedrubbersealingringanddualmetalpartsofthesecondarysealunderthreeworkingconditionsofincreasingfrequency,increasingdisplacementamplitudeandincreasingmediumpressureareobtained.Theresultsshowthatthesecondarysealofhydrodynamicshaftsealofthereactorcoolantpumpisinafrettingfrictionstateunderthenormaloperatingconditionfrequencyof25Hz,amplitudeofabout30μmandmediumpressureof5.3MPa.Thefrictionpropertiesofthesec...