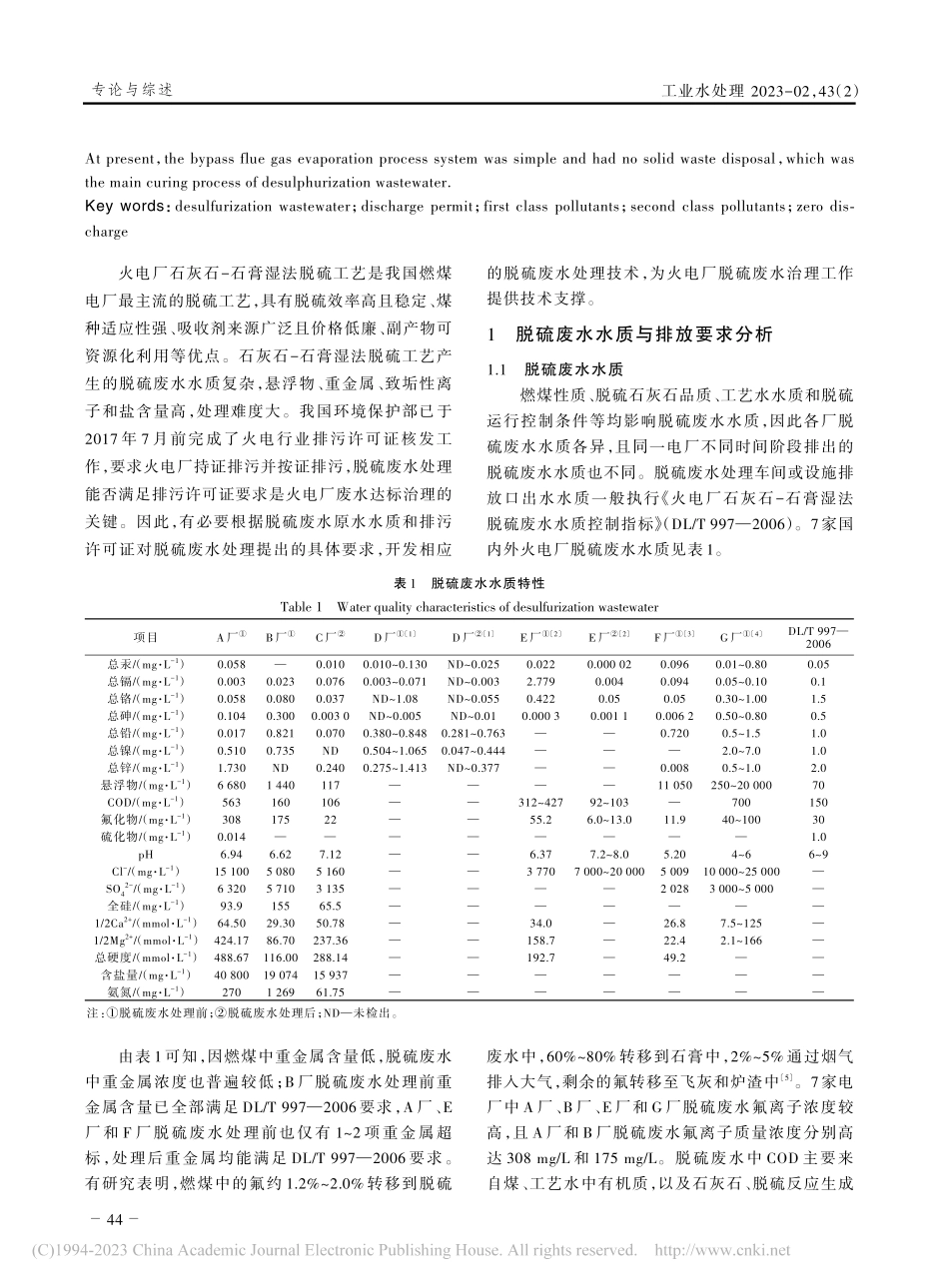

第43卷第2期2023年2月Vol.43No.2Feb.,2023工业水处理IndustrialWaterTreatmentDOI:10.19965/j.cnki.iwt.2021-132443燃煤电厂脱硫废水处理技术现状与发展胡大龙1,余耀宏1,于胜利2,尚卫军3,李亚娟1,李文东2(1.西安西热水务环保有限公司,陕西西安710054;2.锡林郭勒热电有限责任公司,内蒙古锡林郭勒026000;3.北方联合电力有限责任公司,内蒙古呼和浩特010020)[摘要]在分析脱硫废水水质特点,以及调研排污许可证中脱硫废水去向和污染物排放执行标准的基础上,论述了脱硫废水达标处理、厂内回用和零排放的技术路线。排污许可证基本不允许脱硫废水外排,并对脱硫废水车间排放口水质进行了严格限定。约80.0%电厂的污染物因子和限值按《火电厂石灰石-石膏湿法脱硫废水水质控制指标》(DL/T997—2006)执行,部分电厂增加了氨氮污染物因子控制指标、下调了氟化物和COD限值。脱硫废水达标处理,一类污染物重金属主要采用化学沉淀法去除,二类污染物氟化物采用复合盐沉淀技术去除,曝气法和次氯酸钠氧化法相组合的工艺可同步去除脱硫废水中的COD和氨氮。脱硫废水厂内回用方式包括湿除渣和干灰调湿,其中湿除渣系统应主要关注设备腐蚀问题,干灰调湿主要考虑气候以及对周围环境的二次污染问题。脱硫废水零排放采用结晶工艺时需考虑盐的处置以及需通过工艺优化避免产生二次污染物;目前旁路烟气蒸发工艺系统简单、无固废处置问题,是当前脱硫废水固化的主流工艺。[关键词]脱硫废水;排污许可;一类污染物;二类污染物;零排放[中图分类号]X703[文献标识码]A[文章编号]1005-829X(2023)02-0043-10Presentsituationanddevelopmentoftreatmenttechnologyfordesulfurizationwastewaterincoal-firedpowerstationHUDalong1,YUYaohong1,YUShengli2,SHANGWeijun3,LIYajuan1,LIWendong2(1.Xi’anTPRIWaterManagement&EnvironmentProtectionCo.,Ltd.,Xi’an710054,China;2.XilinGolThermalPowerCo.,Ltd.,XilinGol026000,China;3.NorthUnitedPowerCo.,Ltd.,Huhhot010020,China)Abstract:Onthebasisofanalyzingthewaterqualitycharacteristicsofdesulfurizationwastewater,aswellasthedi⁃rectionofdesulfurizationwastewaterandthedischargestandardsofpollutantsinthesewagepermit,thetechnicalrouteofstandardtreatment,reuseandzerodischargeofdesulfurizationwastewaterwerediscussed.Almostallofthedischargepermitbasical...