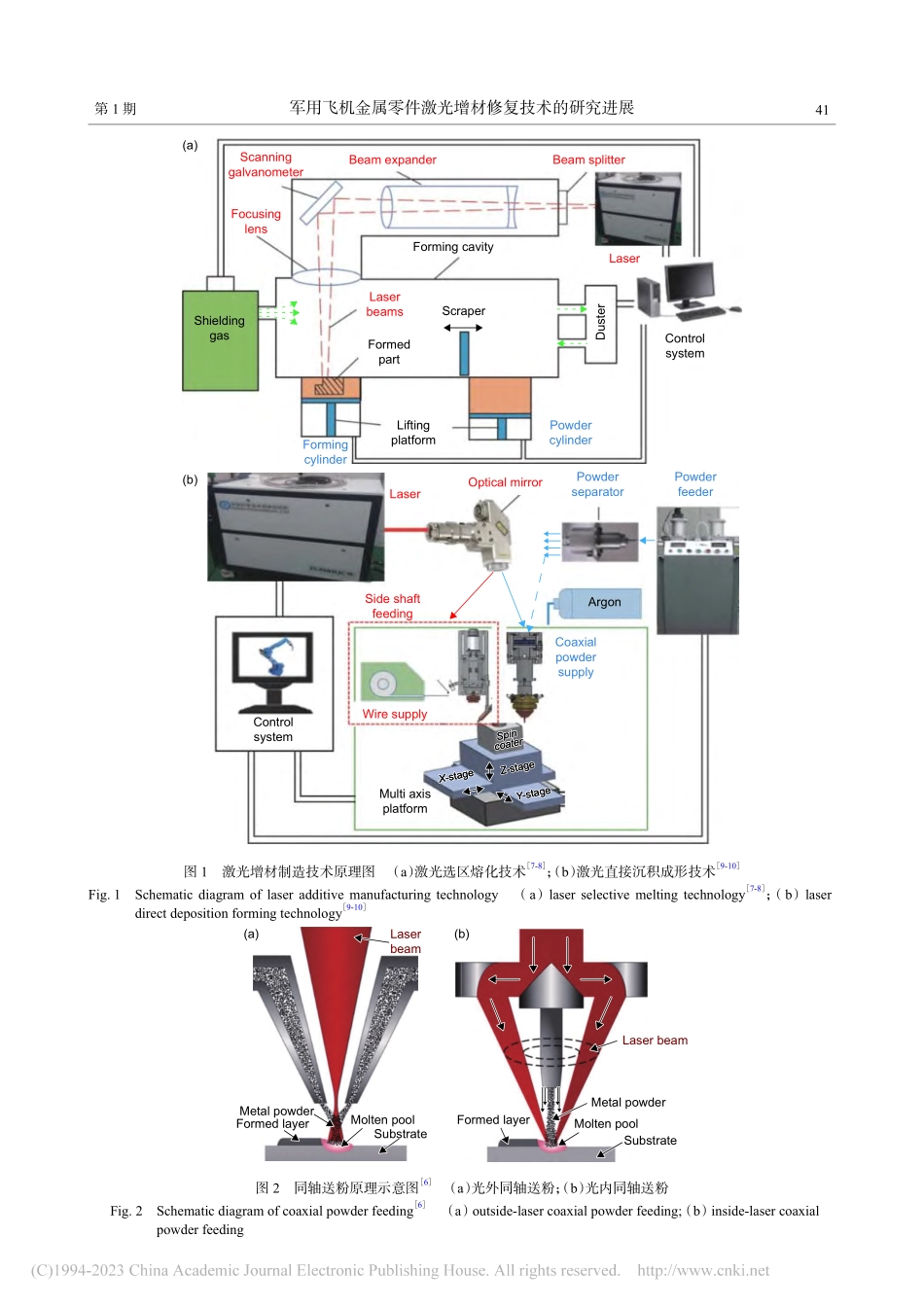

军用飞机金属零件激光增材修复技术的研究进展徐进军,张浩,高德晰,湛阳,江茫,高昆,曾全胜*(湖南省飞机维修工程技术研究中心,长沙410124)摘要:激光增材修复技术适用于军用飞机金属零件的快速高效修复,是延长飞行服役年限和提升自主航空维修能力的重要推力。本文介绍了选区激光熔化成形、激光直接沉积成形、激光熔覆以及激光-电弧复合增材制造等激光增材修复技术特点,阐述了激光增材修复过程中常见的塌边、表面球化、气孔以及裂纹等不同尺度缺陷类型并提出了相应的调控方法,总结了激光能量密度、搭接率、填充材料供给速度、保护气体流量、时间参数和扫描路径等激光增材修复技术工艺优化特点以及施加外加能场和优化设计专用填充材料改善修复性能。最后,列举了激光增材修复技术在飞机机翼梁、涡轮叶盘、单晶叶片以及起落架等金属部件维修中的应用,并对激光增材修复技术在辅助系统设计、多能场融合、评价标准制定以及可移动激光增减材修复设备研发等未来的研究重点和趋势进行了探讨。关键词:激光增材修复;军用飞机;金属零部件;航空维修doi:10.11868/j.issn.1005-5053.2022.000076中图分类号:TG146.21文献标识码:A文章编号:1005-5053(2023)01-0039-12ResearchprogressoflaseradditiverepairtechnologyformilitaryaircraftmetalpartsXUJinjun,ZHANGHao,GAODexi,ZHANYang,JIANGMang,GAOKun,ZENGQuansheng*(HunanAircraftMaintenanceEngineeringTechnologyResearchCenter,Changsha410124,China)Abstract:Laseradditiverepairtechnologyissuitabletorepairthemetalpartsofmilitaryaircraft.Itisanimportantthrusttoprolongtheflightservicelifeandimprovetheabilityofindependentmaintenance.Thispaperintroducedthecharacteristicsoflaseradditiverepairtechnologiessuchasselectivelasermeltingforming,laserdirectdepositionforming,lasercladdingandlaserarccompositeadditivemanufacturing.Thecommontypesofdefectswithdifferentscales,suchasedgecollapse,surfacespheroidization,porosityandcrackintheprocessoflaseradditiverepairweredescribed,andthecorrespondingcontrolmethodswereproposed.Thelaserenergydensity,overlapratio,feedingspeedoffillermaterials,shieldinggasflow,timeparametersandscanningpathoflaseradditiverepairtechnologyweresummarized,andtherepairperformancewasimprovedbytheapplicationofexternalene...