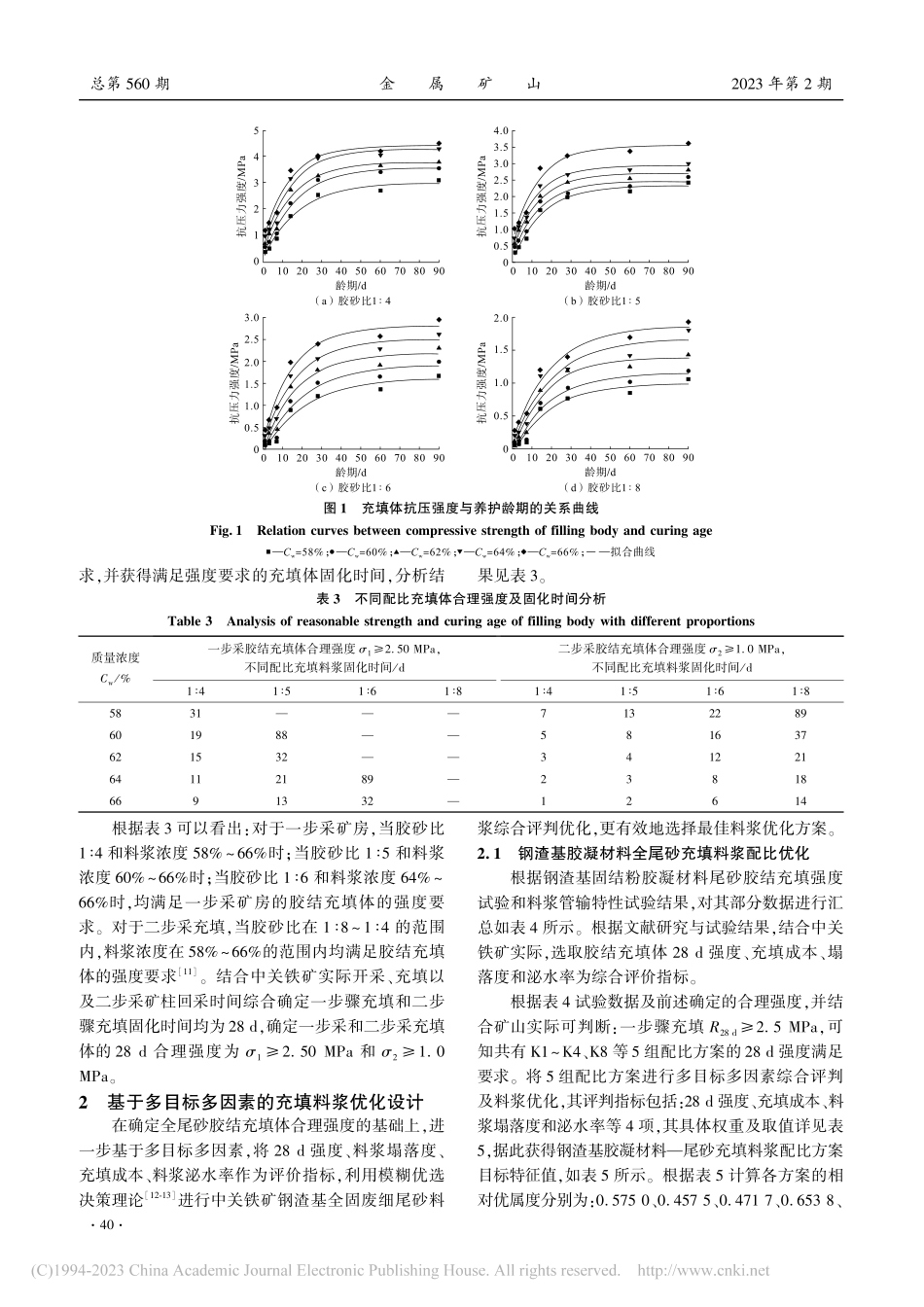

SeriesNo.560February2023金属矿山METALMINE总第560期2023年第2期收稿日期2022-08-22基金项目河北省重点研发计划项目(编号:20374103D)。作者简介杨志强(1972—),男,高级工程师。通信作者王立杰(1972—),女,高级工程师。基于能量匹配的充填体强度设计及料浆配比优化杨志强1王立杰1王社光1高谦2王福全1王庆刚1(1.河北钢铁集团沙河中关铁矿有限公司,河北邢台054100;2.北京科技大学土木与资源工程学院,北京100083)摘要由于各矿山地质条件不同、开采方法及结构参数不同,且影响充填体强度因素多而复杂,给安全经济合理的充填体强度确定带来困难。本研究根据前期胶砂强度试验、管输特性试验的结果,基于充填体与围岩相互作用关系,采用能量耗散理论,分别确定一步采和二步采充填体合理强度;在此基础上,结合料浆管输特性,采用多目标模糊综合评判理论对充填料浆配比进行优化,在满足充填体强度和料浆流动性基础上进一步降低充填成本。研究表明:一步采和二步采充填合理强度分别为2.50MPa和1.0MPa,固化时间均为28d;充填料浆优化配比均为胶砂比1∶5和料浆浓度64%。试验验证表明所得优化配比具有较高可靠性,可为工业充填提供依据。关键词全尾砂胶结充填体能量匹配模糊综合评判配比优化中图分类号TD853.34文献标志码A文章编号1001-1250(2023)-02-038-05DOI10.19614/j.cnki.jsks.202302006StrengthDesignonFillingBodyandOptimizationofSlurryRatioBasedonEnergyMatchingYANGZhiqiang1WANGLijie1WANGSheguang1GAOQian2WANGFuquan1WANGQinggang1(1.ShaheZhongguanIronMineCo.,Ltd.,HebeiIronandSteelGroup,Xingtai054100,China;2.SchoolofCivilandResourceEngineering,UniversityofScienceandTechnologyBeijing,Beijing100083,China)AbstractDuetothedifferentgeologicalconditionsofeachmine,theminingmethodsandstructuralparametersaredif-ferent,andtherearemanyandcomplexfactorsaffectingthestrengthofthefillingbody.Itbringsdifficultiestothedetermina-tionofthestrengthofthefillingbodythatissafe,economicalandreasonable.Basedonthepreviousmortarstrengthtest,there-sultsofthepipelinecharacteristicstest,basedontheinteractionbetweenthebackfillandthesurroundingrock,usingtheener-gydissipationtheory,determinethereasonablestrengthofthebackfillinone-stepminingandtwo-stepminingrespectively;onthebasisof,combinedwiththecharacteristicsofslu...