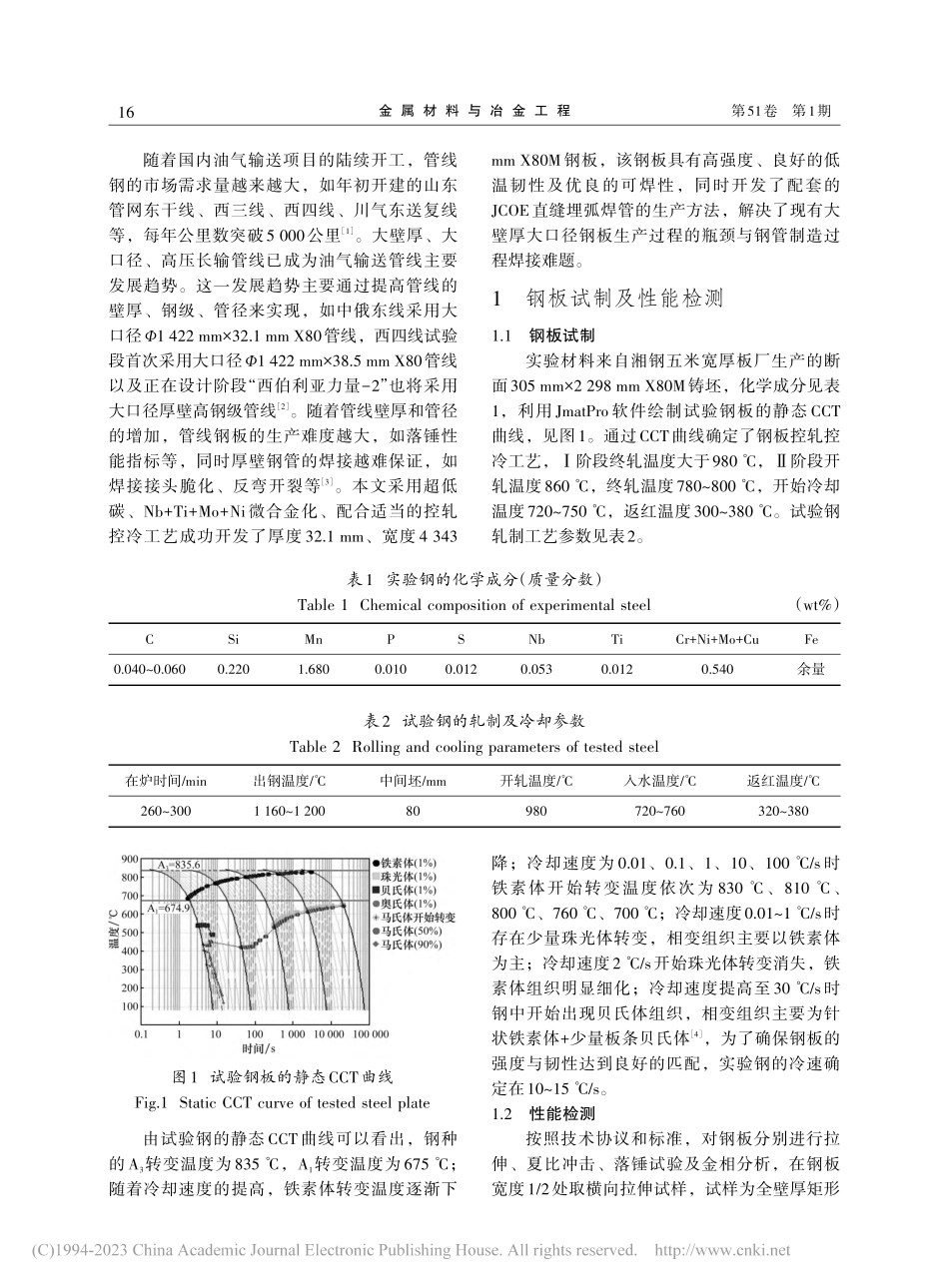

2023年第1期X80级大口径直缝埋弧焊管的开发李中平1,昌发祥2,代志健2,肖甜2,陈礼貌3,罗天宝2,谢平2(1.湘潭钢铁集团有限公司,湖南湘潭411101;2.湖南胜利湘钢钢管有限公司,湖南湘潭411101;3.中国船级社武汉分社,湖北武汉430000)摘要:采用超低碳、Nb+Ti+Mo+Ni微合金化、配合适当的控轧控冷工艺,成功开发了板厚32.1mm、宽度4343mmX80M钢板,钢板具有高强度、良好的低温韧性及优良的可焊性;钢板按照JCOE工艺制管,采用合理的坡口尺寸、焊接工艺参数、扩径率等,保证管体几何尺寸、焊缝、焊缝余高、错边、内外焊道中心线偏移量及头部内外焊道熔合量符合《天然气输送管道用OD1422mmX80直缝埋弧焊管技术条件》的要求,管体屈服强度605~630MPa,抗拉强度680~720MPa,屈强比0.88~0.92;在-20度冲击试验下,焊缝冲击吸收能量150~200J、热影响区冲击吸收能量250~300J。关键词:大口径;X80;埋弧焊管中图分类号:TG142文献标识码:A文章编号:2095-5014(2023)01-0015-05DevelopmentofGradeX80LargeDiameterLongitudinalSubmergedArcWeldedPipeLIZhongping1,CHANGFaxiang2,DAIZhijian2,XIAOTian2,CHENLimao3,LUOTianbao2,XIEPing2(1.HunanXiangtanIronandSteelGroupCo.,Ltd.,Xiangtan411101,China;2.HunanShengliXianggangSteelPipeCo.,Ltd.,Xiangtan411101,China;3.WuhanBranchofChinaClassificationSociety,Wuhan430000,China)ABSTRACT:X80Msteelplatewithwallthicknessof32.1×4343mmhasbeensuccessfullydevelopedbyusingultra-lowcarbon,Nb+Ti+Mo+Nimicroalloyingandpropercontrolledrollingandcontrolledcoolingprocess.Thesteelplatehashighstrength,goodlowtemperaturetoughnessandexcellentweldability;ThesteelplateismanufacturedaccordingtotheJCOEpipemanufacturingprocess,andthereasonablydesignedgroovesize,weldingprocessparameters,diameterexpansionrate,pipebody,weld,weldreinforcement,misalignment,offsetofinnerandouterweldbeadcenterlineandfusionamountofheadinnerandouterweldbeadallmeettherequirementsofOD1422mmX80LSAWpipefornaturalgastransmissionpipeline.Theyieldstrengthofthepipebodyis605~630MPa,thetensilestrengthis680~720MPa,theyieldratiois0.88~0.92,theimpactofweldingseamis150~200J,andtheimpactofheataffectedzoneis250~300J.KEYWORDS:largediameter;X8...