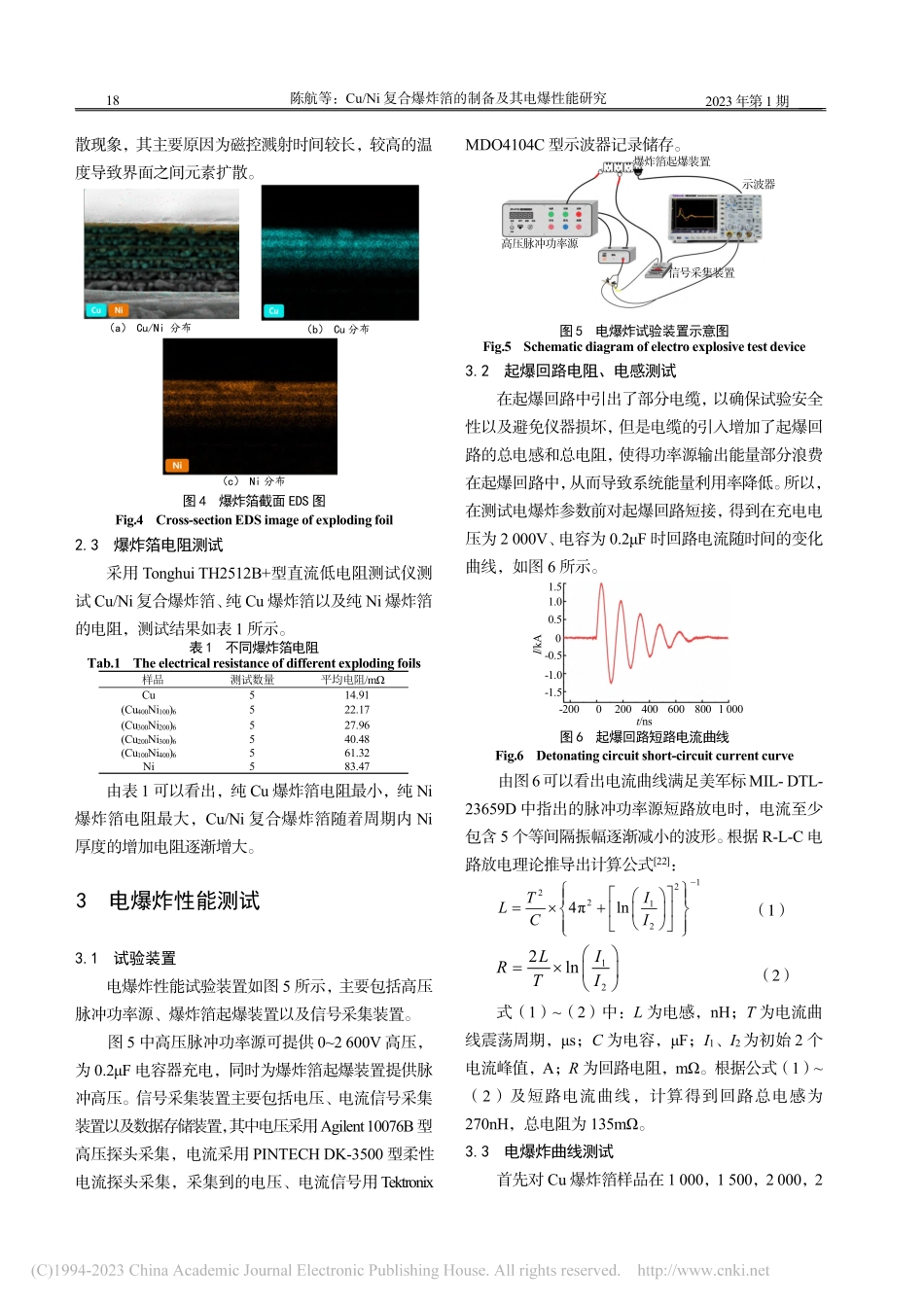

火工品INITIATORS&PYROTECHNICS文章编号:1003-1480(2023)01-0016-06Cu/Ni复合爆炸箔的制备及其电爆性能研究陈航,唐书缘,刘佳兴,周全,代波,任勇(西南科技大学环境友好能源材料国家重点实验室,四川绵阳,621010)摘要:采用磁控溅射、光刻及湿法刻蚀等工艺制备了厚度为3μm的Cu爆炸箔、Ni爆炸箔以及Cu/Ni复合爆炸箔,采用XRD、SEM及EDS对样品进行物相及截面形貌表征,并对爆炸箔电阻及其电爆性能进行测试。结果表明:随着Ni元素的增加,复合爆炸箔电阻逐渐增大;在1000V充电电压下,Cu膜厚度为300nm、Ni膜厚度为200nm、调制周期为6的Cu/Ni复合爆炸箔(Cu300Ni200)6的爆发电流是Cu爆炸箔的2.33倍,是Ni爆炸箔的1.56倍;其爆发功率是Cu爆炸箔的3.81倍,是Ni爆炸箔的1.45倍;其能量利用率为30.96%,是Cu爆炸箔的1.29倍,是Ni爆炸箔的1.28倍。关键词:爆炸箔;Cu/Ni;电爆性能;磁控溅射中图分类号:TJ450.3文献标识码:ADOI:10.3969/j.issn.1003-1480.2023.01.004PreparationandStudyonElectricalPerformanceofCu/NiExplodingFoilCHENHang,TANGShu-yuan,LIUJia-xing,ZHOUQuan,DAIBo,RENYong(StateKeyLaboratoryofEnvironment-friendlyEnergyMaterials,SouthwestUniversityofScienceandTechnology,Mianyang,621010)Abstract:TheCu,NiandCu/Niexplodingfoilswith3μmthicknesswerepreparedbymagnetronsputtering,photolithographyandwetetching.XRD,SEMandEDSwereusedtocharacterizethephaseandcross-sectionalmorphologyofthesamples,theresistanceandtheelectroexplosiveperformanceoftheexplodingfoilsweretested.TheresultsshowthatwiththeincreaseofNielement,theresistanceoftheexplodingfoilgraduallyincrease.Under1000Vchargingvoltage,theexplosioncurrentofthe(Cu300Ni200)6sample,whichhas300nmthicknessofCufilmand200nmthicknessofNifilmasaperiodandatotalof6periods,is2.33timesthatoftheCuexplodingfoil,1.56timesthatoftheNiexplodingfoil,andtheexplosionpoweris3.81timesthatofCuexplosionfoiland1.45timesthatofNiexplosionfoil.Theenergyutilizationrateofthe(Cu300Ni200)6sampleis30.96%,whichis1.29timesthatoftheCuexplosionfoiland1.28timesthatoftheNiexplosionfoil.Keywords:Explodingfoil;Cu/Ni;Electroexplosiveperformance;Magnetronsputtering爆炸箔起爆系统因其安全性好、环境适应性强、作用时间短...