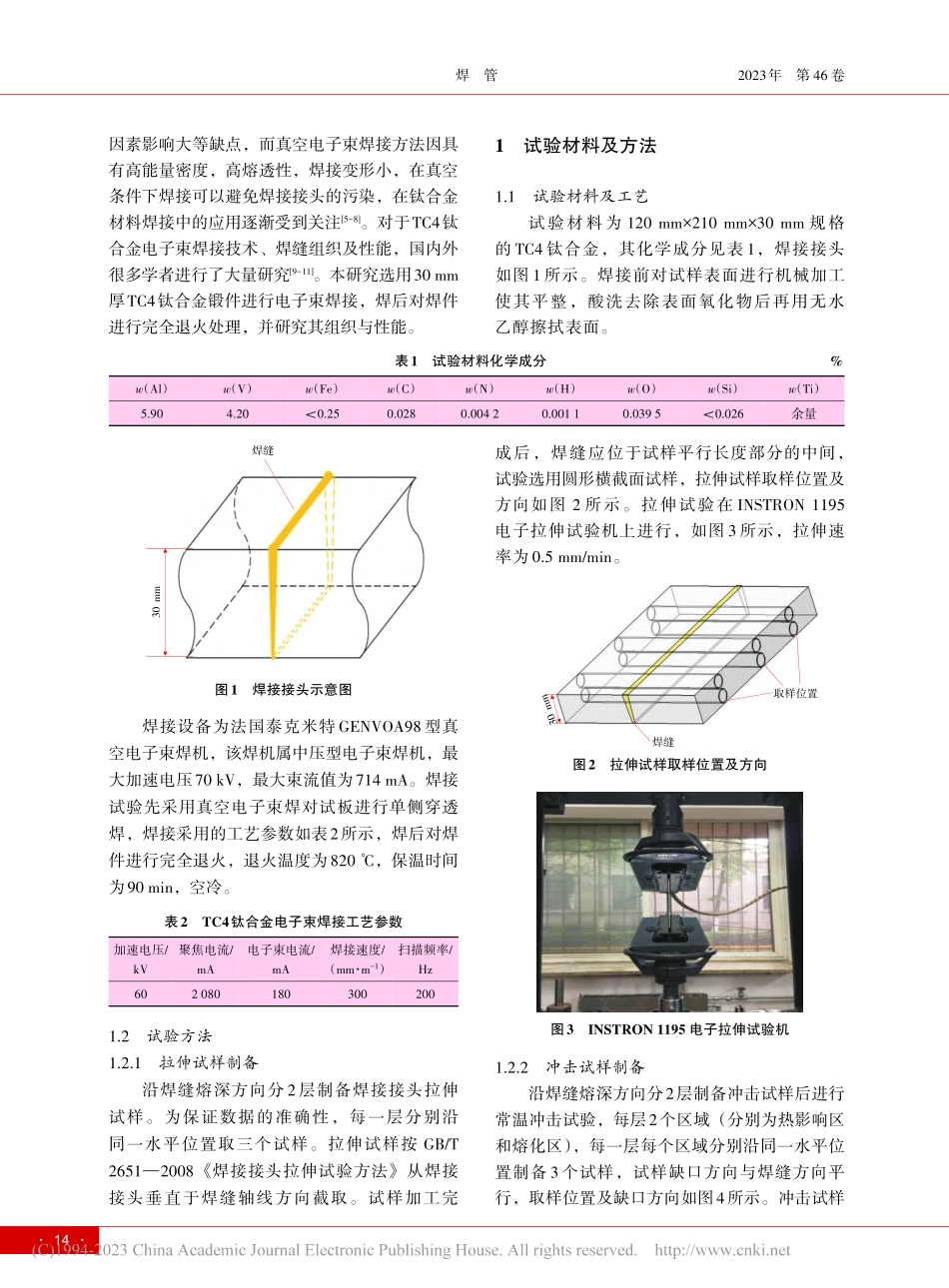

试验与研究第46卷第3期2023年3月Vol.46No.3Mar.2023HANGUAN焊管WELDEDPIPEANDTUBE30mm退火态TC4钛合金EBW接头组织与性能研究王维贤,庄明祥,刘波,刘永强(中航西安飞机工业集团股份有限公司,西安710089)摘要:为了提升钛合金的焊接效率和质量,采用电子束焊接方式对30mm退火态TC4钛合金进行焊接试验,并对焊接接头进行力学性能检测、显微组织分析及残余应力测试,通过扫描电镜对断口形貌进行分析,研究完全退火态TC4钛合金EBW接头组织与性能。结果表明,接头焊缝区由针状马氏体α′相和分布在原始β晶界的α相组成,接头热影响区由初生α相、针状马氏体α′相以及少量β相组成。EBW接头抗拉强度平均值略高于母材,EBW接头第二层焊缝区及热影响区冲击功均低于母材,同时两种接头断口形貌均发现大量韧窝,为韧性断裂。接头最大残余拉应力值约为150MPa,在平行和垂直焊接方向,残余拉应力最大值均出现在焊缝上表面附近区域,而残余压应力最大值均出现在焊缝下表面附近区域。关键词:TC4钛合金;电子束焊接;显微组织;力学性能中图分类号:TG406文献标识码:ADOI:10.19291/j.cnki.1001-3938.2023.03.003MicrostructureandPropertiesof30mmAnnealedTC4TitaniumAlloyEBWJointsWANGWeixian,ZHUANGMingxiang,LIUBo,LIUYongqiang(AVICXi'anAircraftIndustryGroupCo.,Ltd.,Xi'an710089,China)Abstract:Inordertoimprovetheweldingefficiencyandqualityoftitaniumalloy,theelectronbeamweldingwasusedtoweldthe30mmannealedTC4titaniumalloy,andthemechanicalproperties,microstructureandresidualstressoftheweldedjointweretested.Thefracturemorphologywasanalyzedbyscanningelectronmicroscope,andthemicrostructureandpropertiesofthefullyannealedTC4titaniumalloyEBWjointwerestudied.Theresultsshowthatthejointweldzoneiscomposedofacicularmartensiteα'phaseandαphasedistributedintheoriginalβgrainboundary,thejointheataffectedzoneiscomposedofαphase,acicularmartensiteα′phaseandsmallamountβphasecomposition.TheaveragetensilestrengthofEBWjointisslightlyhigherthanthatofthebasemetal.TheimpactenergyofthesecondlayerofweldzoneandheataffectedzoneofEBWjointislowerthanthatofthebasemetal.Meanwhile,alargenumberofdimplesarefoundonthefracturemorphologyofbothjoints,whichisductilefracture.Themaximumresidualtensile...