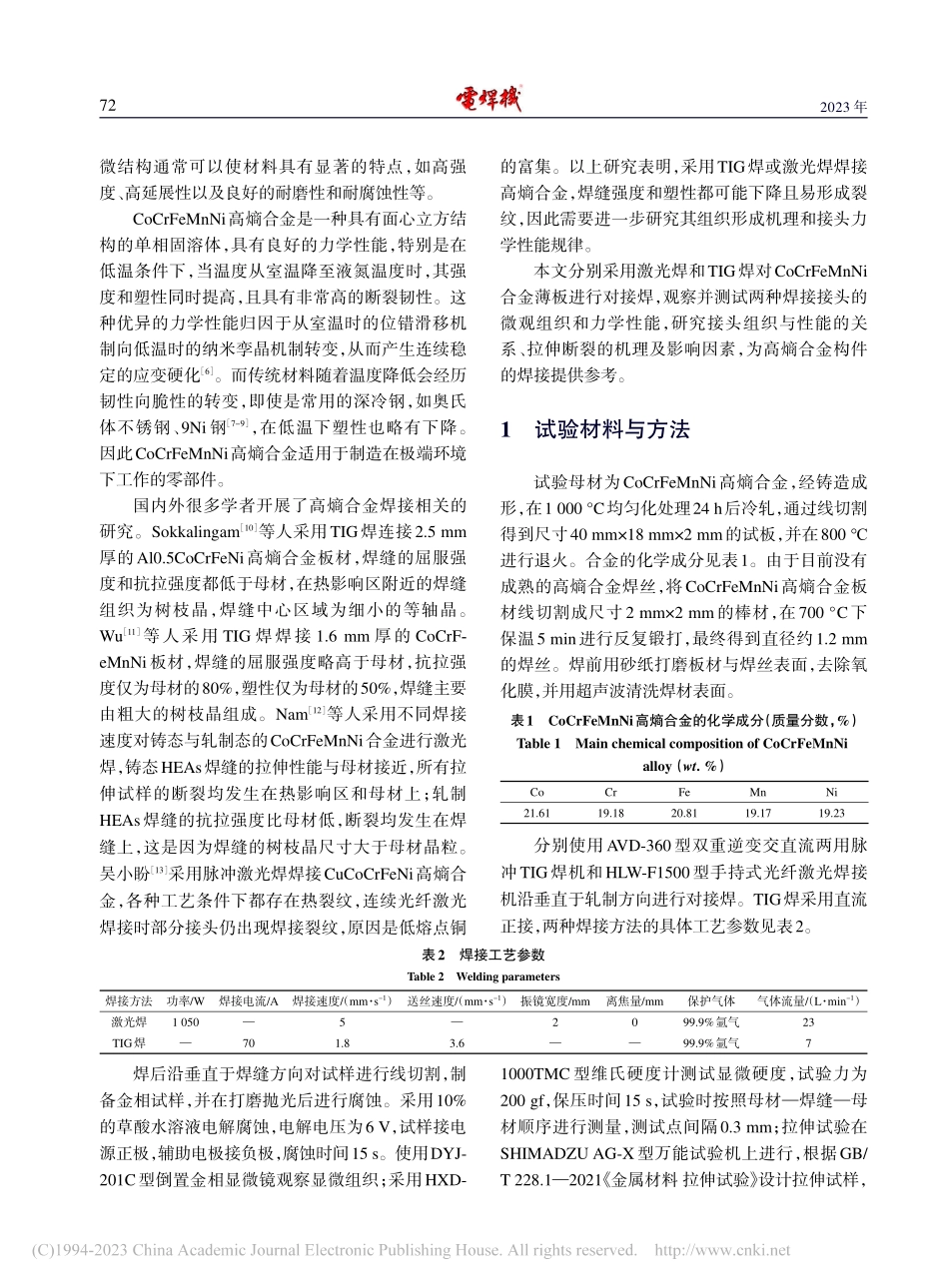

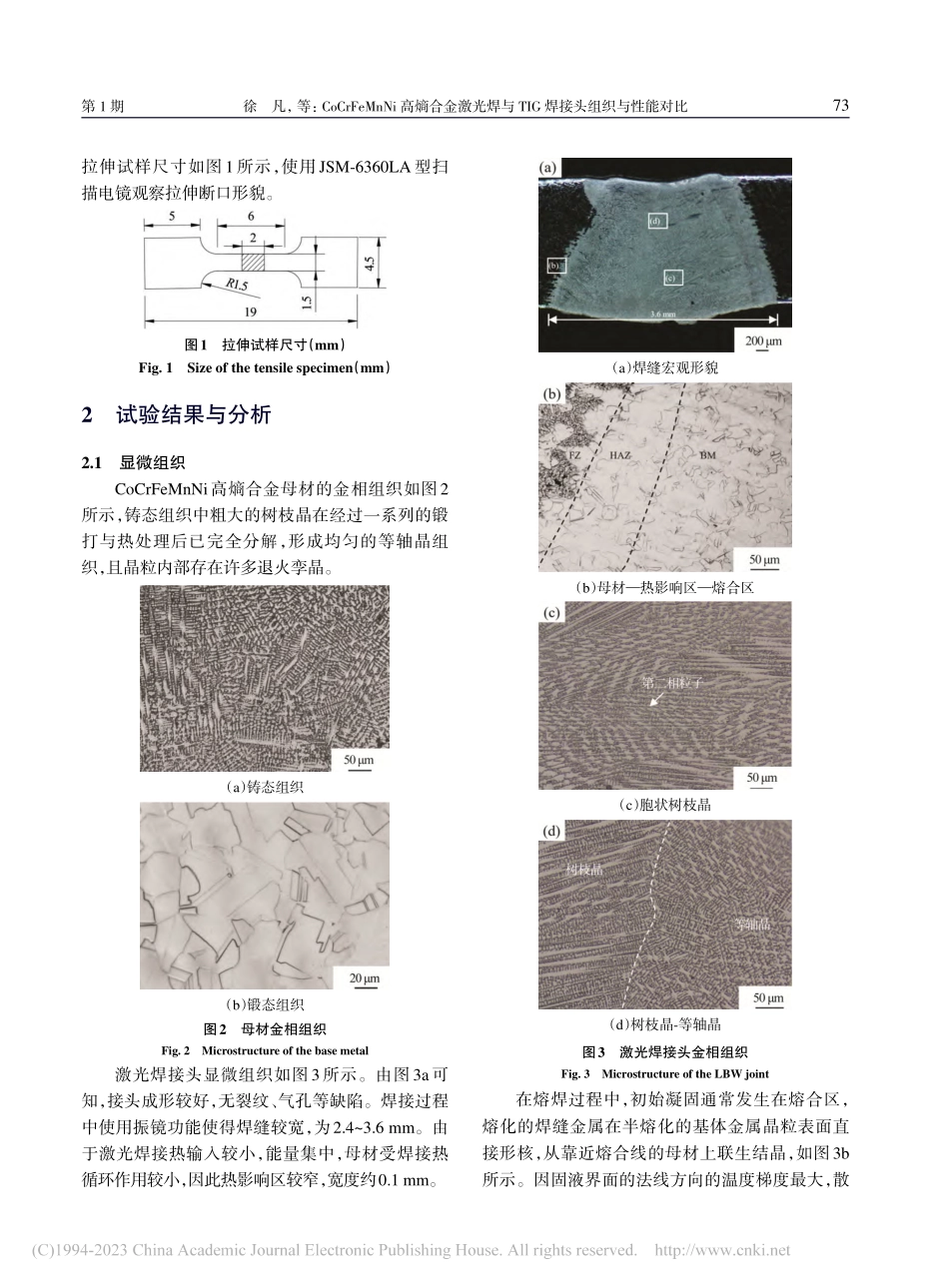

ElectricWeldingMachineVol.53No.1Jan.2023第53卷第1期2023年1月CoCrFeMnNi高熵合金激光焊与TIG焊接头组织与性能对比徐凡,田松亚,张根元,季珊林,孙华琛河海大学机电工程学院,江苏常州213022摘要:为探究高熵合金作为结构材料应用的适用性,采用激光焊与TIG焊对板厚2mm的CoCrFeMnNi高熵合金进行连接,并对母材及两种焊接接头进行组织观察、显微硬度测试和拉伸性能测试。结果表明,激光焊与TIG焊焊缝晶粒形态基本一致,都是由垂直于熔合线方向生长的胞状树枝晶和焊缝中心处的等轴晶组成,但激光焊焊缝区晶粒较细;母材的强度与塑性最好,激光焊焊接接头次之,氩弧焊焊接接头最低,而两种焊接工艺得到的焊缝以及母材的显微硬度则恰好相反。关键词:高熵合金;激光焊;钨极氩弧焊;显微组织;力学性能中图分类号:TG457.1文献标识码:A文章编号:1001-2303(2023)01-0071-06ComparisonontheMicrostructureandMechanicalPropertiesofCoCrF‐eMnNiHigh-entropyAlloysweldedJointsbyLaserWeldingandGasTungstenArcWeldingXUFan,TIANSongya,ZHANGGenyuan,JIShanlin,SUNHuachenCollegeofMechanicalandElectronicEngineering,HohaiUniversity,Changzhou213022,ChinaAbstract:Toexploretheapplicabilityofhighentropyalloysasstructuralmaterials,theCoCrFeMnNihigh-entropyalloyssheetsampleswiththethicknessof2mmwereweldedbylaserbeamweldingandgastungstenarcwelding,respectively.Andthemicrostructureobservation,hardnesstestandtensilepropertytestwerecarriedoutontheweldedjoints..Theresultsshowthatthegrainmorphologytransformationoftheweldzonebylaserbeamweldingandgastungstenarcweldingisbasi‐callythesameinthesolidificationprocess,whichiscomposedofcellulardendritesperpendiculartothefusionlineandequiaxedcrystalsinthemiddleoftheweld.Butthegrainoflaserbeamweldingspecimensisfiner.Thehardnessoftheweldobtainedbythetwoweldingprocessesisbothhigher,butthestrengthandductilityoftheweldedjointareslightlylowerthanthatofthebasemetal.Thisstudyhascertainreferencesignificancefortheapplicationofhighentropyalloysinthefuture.Keywords:high-entropyalloys;laserbeamwelding;gastungstenarcwelding;microstructure;mechanicalproperty引用格式:徐凡,田松亚,张根元,等.CoCrFeMnNi高熵合金激光焊与TIG焊接头组...