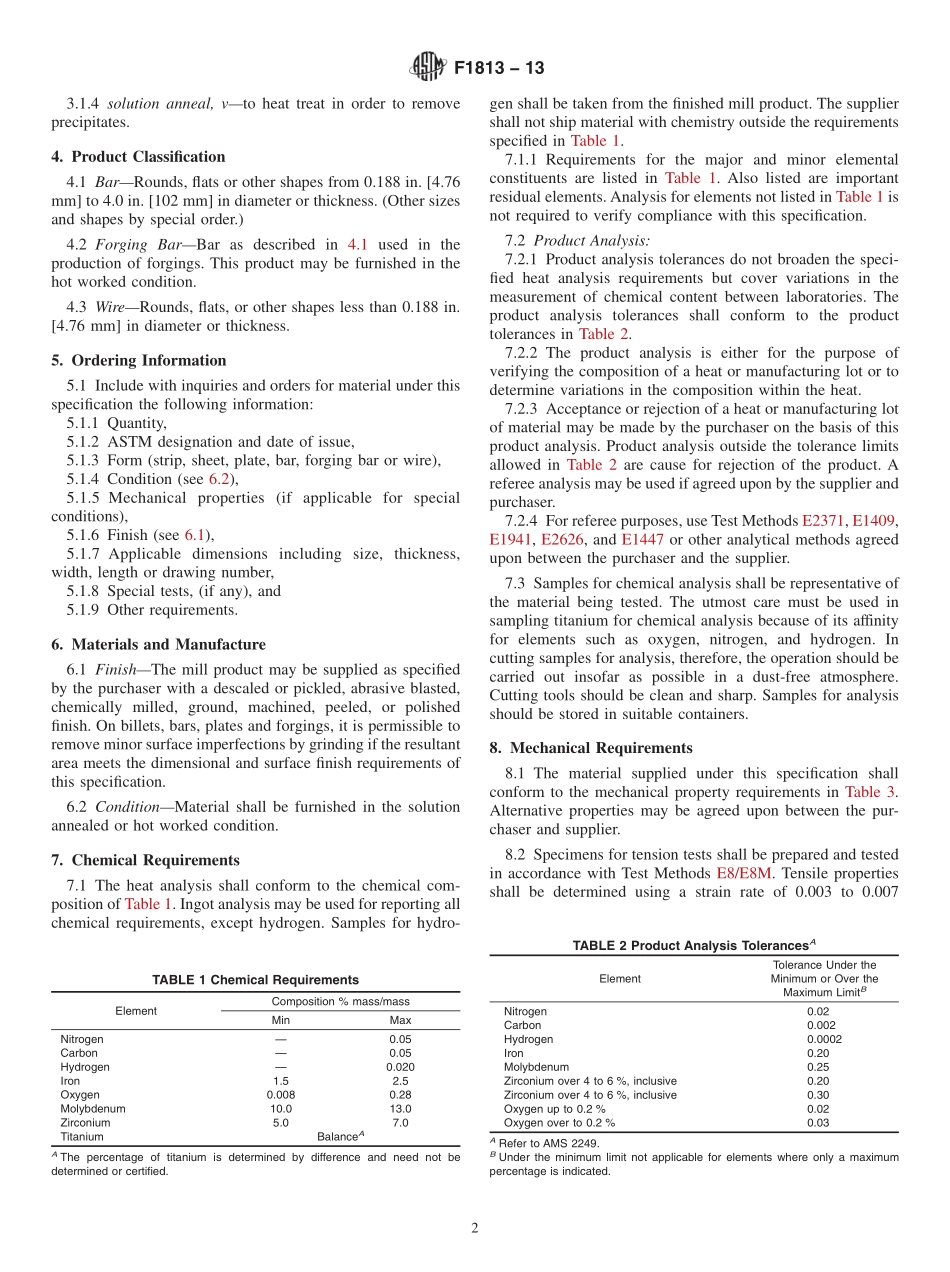

Designation:F1813−13StandardSpecificationforWroughtTitanium-12Molybdenum-6Zirconium-2IronAlloyforSurgicalImplant(UNSR58120)1ThisstandardisissuedunderthefixeddesignationF1813;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thisspecificationcoversthechemical,mechanical,andmetallurgicalrequirementsforwroughttitanium-12molybdenum-6zirconium-2ironalloymillproductstobeusedinthemanufactureofsurgicalimplants.21.2ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.2.ReferencedDocuments2.1ASTMStandards:3E8/E8MTestMethodsforTensionTestingofMetallicMa-terialsE29PracticeforUsingSignificantDigitsinTestDatatoDetermineConformancewithSpecificationsE112TestMethodsforDeterminingAverageGrainSizeE1409TestMethodforDeterminationofOxygenandNitro-geninTitaniumandTitaniumAlloysbytheInertGasFusionTechniqueE1447TestMethodforDeterminationofHydrogeninTita-niumandTitaniumAlloysbyInertGasFusionThermalConductivity/InfraredDetectionMethodE1941TestMethodforDeterminationofCarboninRefrac-toryandReactiveMetalsandTheirAlloysbyCombustionAnalysisE2371TestMethodforAnalysisofTitaniumandTitaniumAlloysbyAtomicEmissionPlasmaSpectrometry(With-drawn2013)4E2626GuideforSpectrometricAnalysisofReactiveandRefractoryMetalsF67SpecificationforUnalloyedTitanium,forSurgicalIm-plantApplications(UNSR50250,UNSR50400,UNSR50550,UNSR50700)F748PracticeforSelectingGenericBiologicalTestMethodsforMaterialsandDevicesIEEE/ASTMSI10AmericanNationalStandardforMetricPractice2.2AerospaceMaterialsSpecification:5AMS2249ChemicalCheckAnalysisLimits,TitaniumandTitaniumAlloysAMS2631UltrasonicInspection—TitaniumandTit...