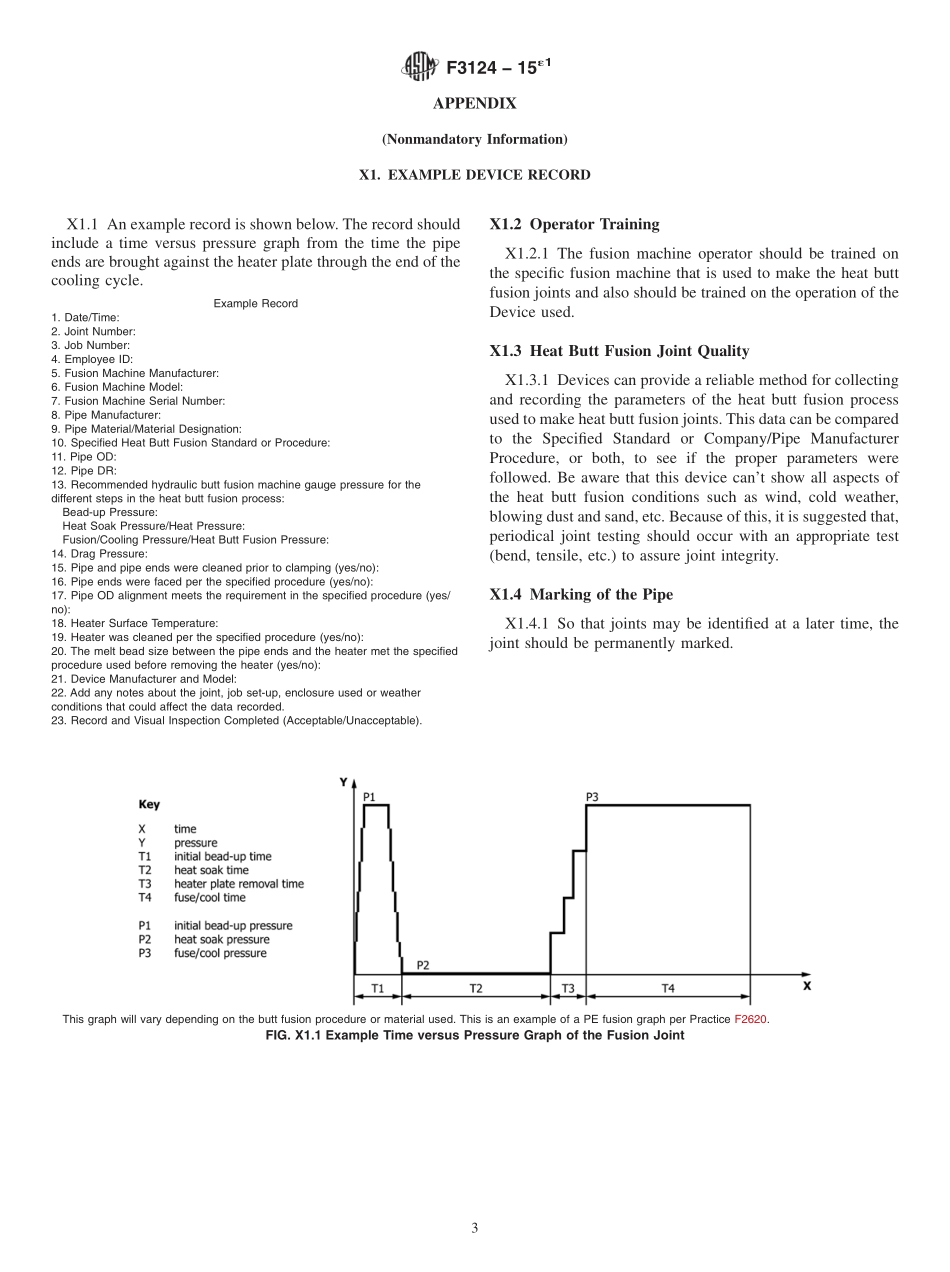

Designation:F3124−15´1StandardPracticeforDataRecordingtheProcedureusedtoProduceHeatButtFusionJointsinPlasticPipingSystemsorFittings1ThisstandardisissuedunderthefixeddesignationF3124;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ε1NOTE—ThetitlewaseditoriallycorrectedandkeywordswereaddedinMarch2015.1.Scope1.1Thispracticespecifiesthedatarecordinginformationthatisrecorded,whendatarecordingequipmentisused,onbuttfusionjointsinaplasticpipingsysteminordertocomparetheprocedureusedinmakingthejointtotheheatbuttfusionjoiningprocedurespecified.Thispracticeissuitableforusewithallheatbuttfusionjoiningproceduresthatrequiremeasurabletimeandpressureprofiles,suchasPracticeF2620,SpecificationF2785,SpecificationF2945internationalstan-dardsorotherqualifiedprocedures.Thispracticeappliestohydraulicallyoperatedheatbuttfusionmachinesonlyanddoesnotapplytomanuallyoperatedfusionmachinesorspecializedfabricationequipmentforfittingsinacontrolledenvironmentwithproprietaryproceduresandprocesses.1.2Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:F2620PracticeforHeatFusionJoiningofPolyethylenePipeandFittingsF2785SpecificationforPolyamide12GasPressurePipe,Tubing,andFittingsF2945SpecificationforPolyamide11GasPressurePipe,Tubing,andFittings3.Terminology3.1Definitions:3.1.1DataRecordingDevice(“Device”)—Thisisaninstru-mentthatobtainsandstoresinformation.3.1.1.1Discussion—Thisisgenerallyanelectronicdevicethatacceptssensorinputforpressureandtimeandmanualinputforotherinformation.TheseDevicesaretypicallysmall,batterypowered,portable,andequippedwithamicroprocessor,inte...