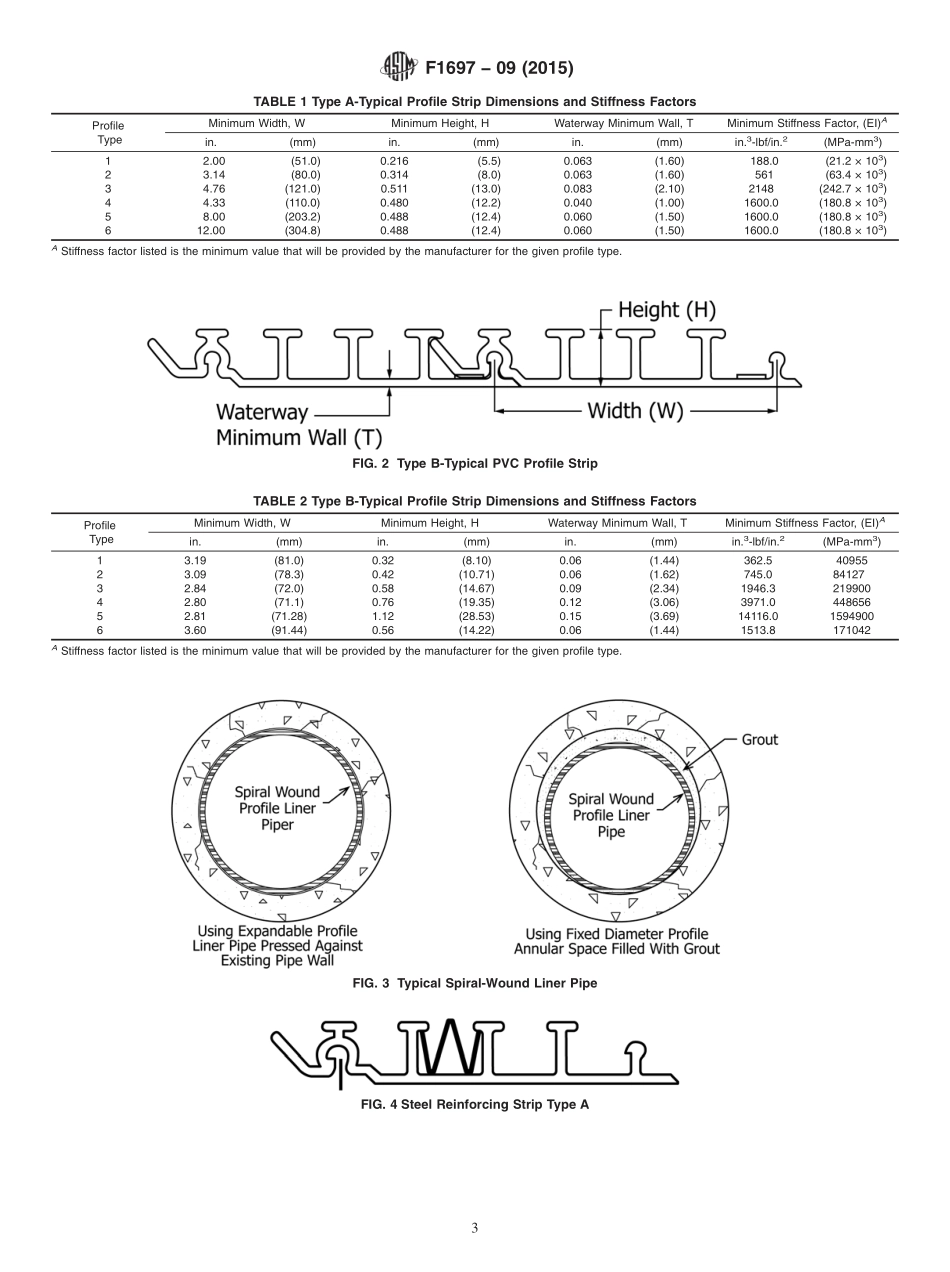

Designation:F1697−09(Reapproved2015)StandardSpecificationforPoly(VinylChloride)(PVC)ProfileStripforMachineSpiral-WoundLinerPipeRehabilitationofExistingSewersandConduit1,2ThisstandardisissuedunderthefixeddesignationF1697;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thisspecificationcoversrequirementsandtestmethodsformaterials,dimensions,workmanship,stiffnessfactor,ex-trusionquality,andaformofmarkingforextrudedpoly(vinylchloride)(PVC)profilestripsusedformachinemadefieldfabricationofspirallywoundpipelinersintherehabilitationofavarietyofgravityapplicationssuchassanitarysewers,stormsewers,andprocesspipingindiametersof6to180in.andforsimilarsizesofnon-circularpipelinessuchasarchedorovalshapesandrectangularshapes.1.2Profilestripproducedtothisspecificationisforuseinfieldfabricationofspirallywoundlinerpipesinnonpressuresewerandconduitrehabilitation,wherethespirallywoundlinerpipeisexpandeduntilitpressesagainsttheinteriorsurfaceoftheexistingsewerorconduit,or,alternatively,wherethespirallywoundlinerpipeisinsertedasafixeddiameterintotheexistingsewerorconduitandtheannularspacebetweenthelinerpipeandtheexistingsewerorconduitisgrouted.1.3Thisspecificationincludesextrudedprofilestripsmadeonlyfrommaterialsspecifiedin5.1.1.4Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.5Thefollowingprecautionarycaveatpertainsonlytothetestmethodportion,Section11,ofthisspecification:Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafetyandhealthpracticesanddeterminetheapplicabilityofregulatorylimita-tionspriortouse.2.ReferencedDocuments2.1ASTMStan...