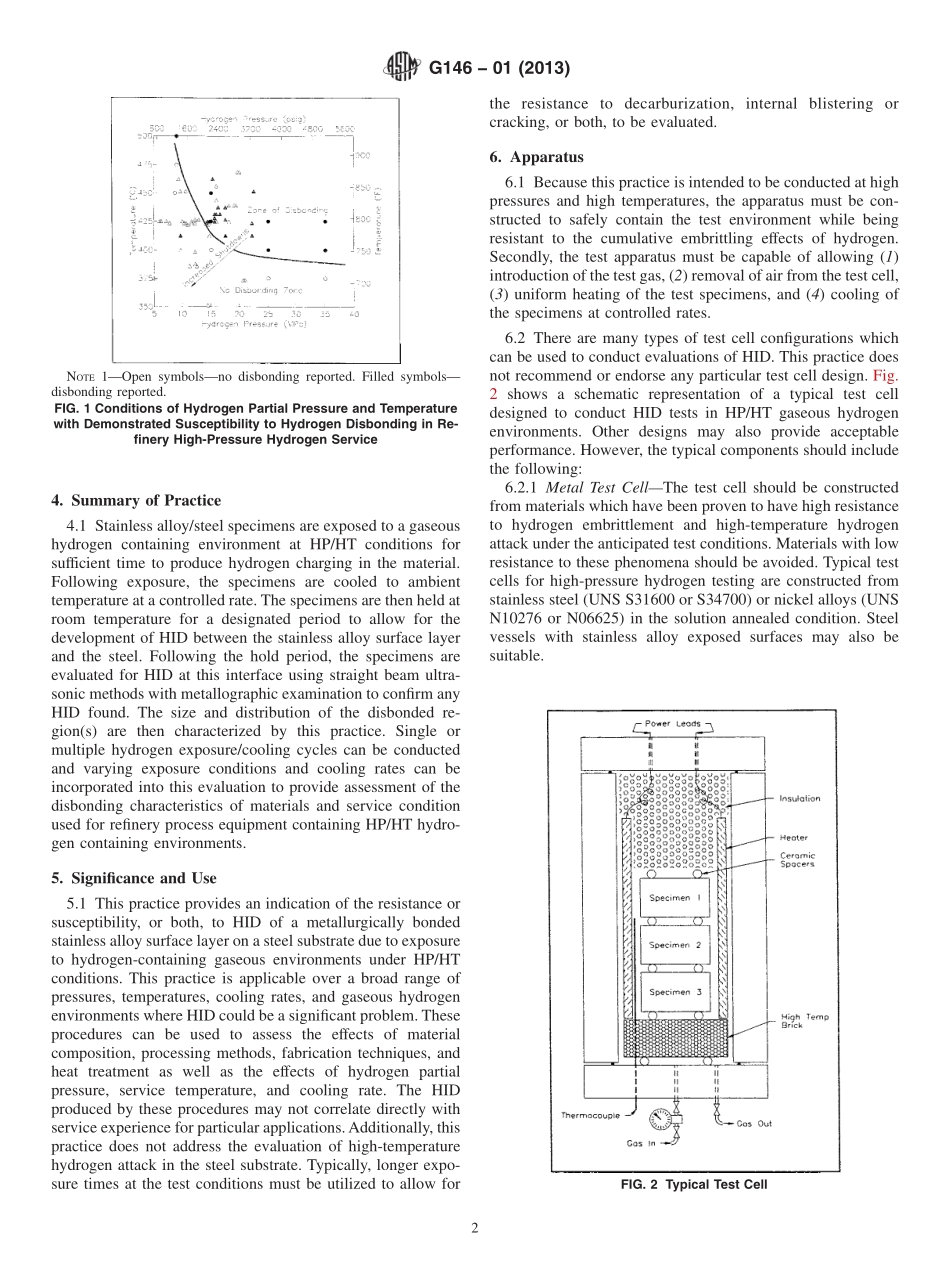

Designation:G146−01(Reapproved2013)StandardPracticeforEvaluationofDisbondingofBimetallicStainlessAlloy/SteelPlateforUseinHigh-Pressure,High-TemperatureRefineryHydrogenService1ThisstandardisissuedunderthefixeddesignationG146;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thispracticecoversaprocedurefortheevaluationofdisbondingofbimetallicstainlessalloy/steelplateforuseinrefineryhigh-pressure/high-temperature(HP/HT)gaseoushy-drogenservice.Itincludesproceduresto(1)producesuitablelaboratorytestspecimens,(2)obtainhydrogenchargingcon-ditionsinthelaboratorythataresimilartothosefoundinrefineryHP/HThydrogengasserviceforevaluationofbime-tallicspecimensexposedtotheseenvironments,and(3)performanalysisofthetestdata.Thepurposeofthispracticeistoallowforcomparisonofdataamongtestlaboratoriesontheresistanceofbimetallicstainlessalloy/steelstohydrogen-induceddisbonding(HID).1.2Thispracticeappliesprimarilytobimetallicproductsfabricatedbyweldoverlayofstainlessalloyontoasteelsubstrate.Mostoftheinformationdevelopedusingthisprac-ticehasbeenobtainedforsuchmaterials.Theproceduresdescribedherein,mayalsobeappropriateforevaluationofhotrollbonded,explosivebonded,orothersuitableprocessesforapplyingstainlessalloysonsteelsubstrates.However,duetothebroadrangeofpossiblematerials,testconditions,andvariationsintestprocedures,itisuptotheuserofthispracticetodeterminethesuitabilityandapplicabilityoftheseproce-duresforevaluationofsuchmaterials.1.3ThispracticeisintendedtobeapplicableforevaluationofmaterialsforserviceconditionsinvolvingseverehydrogenchargingwhichmayproduceHIDasshowninFig.1forstainlesssteelweldoverlayonsteelequipment(seeRefs1and2inAppendixX1).However,itshouldbenotedthatthispracticemaynotbeappropriateforformsofbimetallicconstructionorserviceconditionswhichhavenotbeenob-serve...