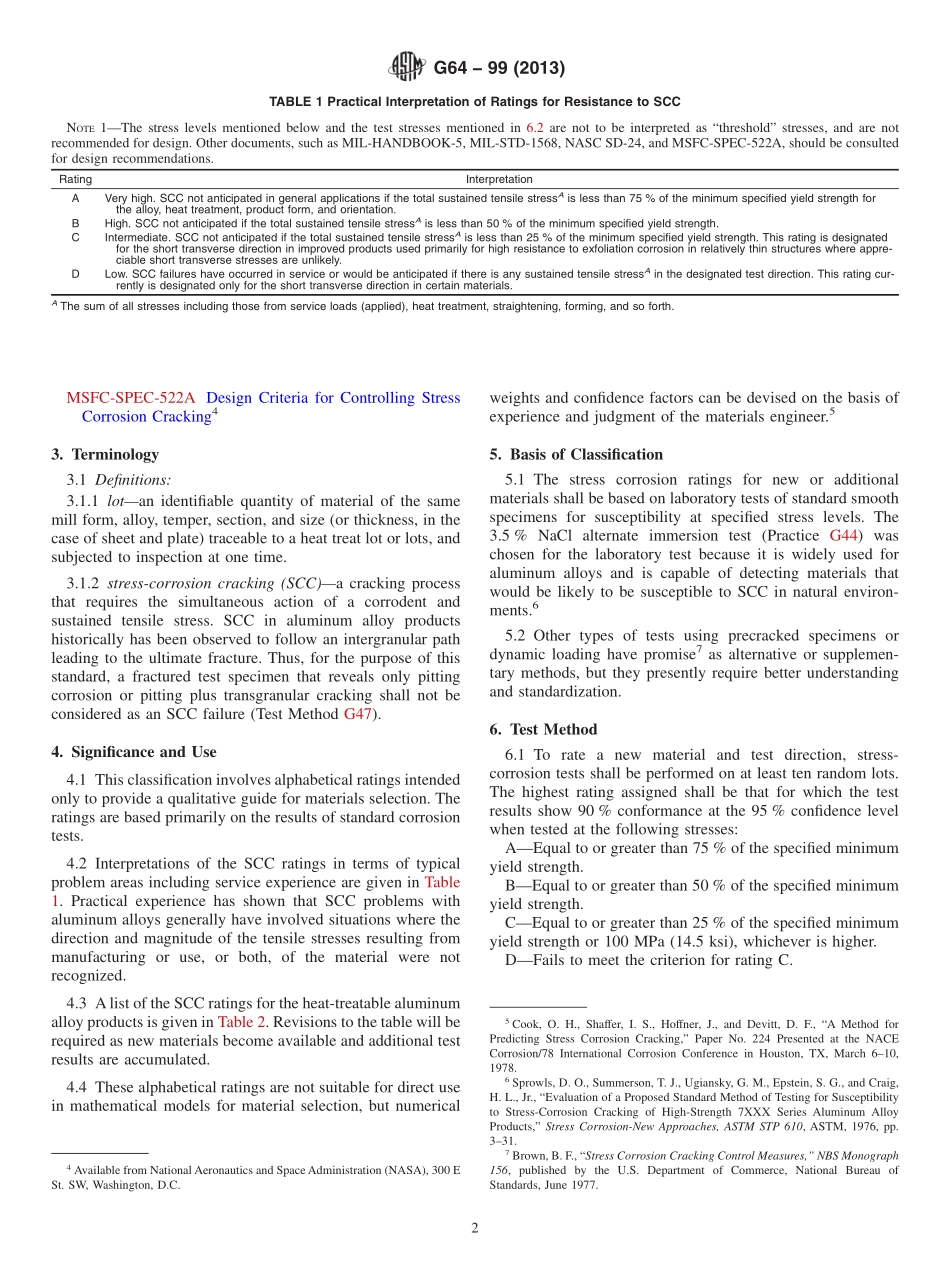

Designation:G64−99(Reapproved2013)StandardClassificationofResistancetoStress-CorrosionCrackingofHeat-TreatableAluminumAlloys1ThisstandardisissuedunderthefixeddesignationG64;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.INTRODUCTIONStresscorrosionbehaviorisanimportantcharacteristictobeconsideredwhenoptimizingthechoiceofmaterialforanengineeringstructure.Unfortunately,thereisnogenerallyacceptedscaleformeasuringit,andstresscorrosiontendenciesaredifficulttodefinebecauseofthecomplexinterdependenceofthematerial,tensilestress,environment,andtime.Conventionaltest-dependenttypesoflaboratorystresscorrosiondatahaveonlyverylimitedapplicabilityinmathematicalmodelsusedformaterialsselection.Thisstandardisintendedtoprovideaqualitativeclassificationoftherelativeresistancetostresscorrosioncracking(SCC)ofhigh-strengthaluminumalloystoassistintheselectionofmaterials.Theclassificationisbasedonacombinationofserviceexperienceandawidelyacceptedlaboratorycorrosiontest.Itiscautioned,however,thatanysuchgeneralizedclassificationofalloyscaninvolveanoversimplificationinregardtotheirbehaviorinunusualenvironments.Moreover,thequantitativepredictionoftheserviceperformanceofamaterialinaspecificsituationisoutsidethescopeofthisstandard.1.Scope1.1ThisclassificationcoversalphabeticalratingsoftherelativeresistancetoSCCofvariousmillproductformsofthewrought2XXX,6XXX,and7XXXseriesheat-treatedalumi-numalloysandtheprocedurefordeterminingtheratings.1.2Theratingsdonotapplytometalinwhichthemetal-lurgicalstructurehasbeenalteredbywelding,forming,orotherfabricationprocesses.1.3ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandard...