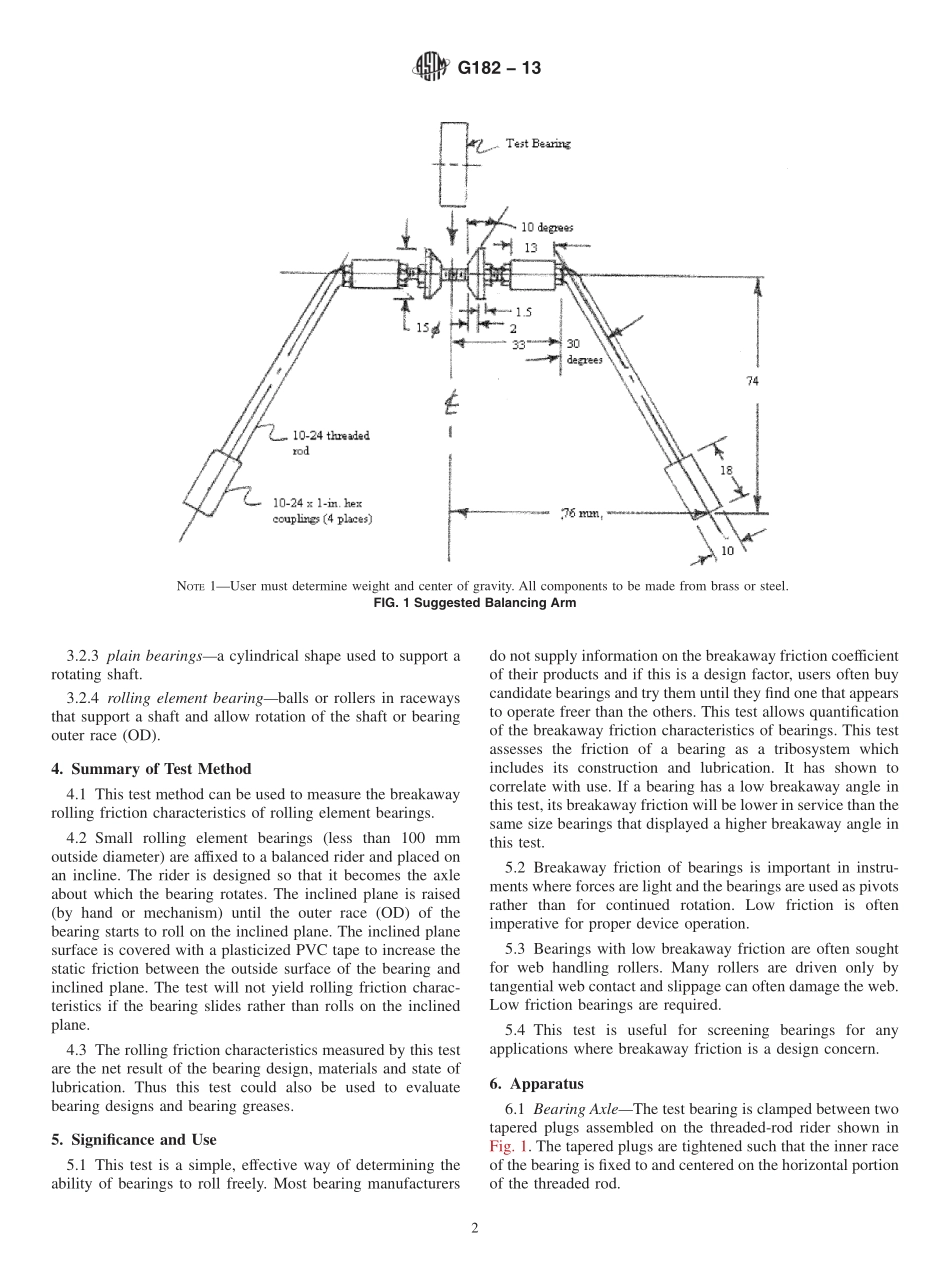

Designation:G182−13StandardTestMethodforDeterminationoftheBreakawayFrictionCharacteristicsofRollingElementBearings1ThisstandardisissuedunderthefixeddesignationG182;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1ThistestmethodisanextensionofTestMethodG164andusesaninclinedplaneandapaperclipridertodetectthepresenceorabsenceoflubricantsonthesurfacesofflexiblewebs.Astudytoidentifyfreespinningorlowrollingfrictionbearingsindicatedthatthepaperclipfrictiontestcouldbeusedforrollingfrictionbysimplyreplacingthepaperclipwitharollingelementbearingonanaxle.Theangleoftheinclinedplaneatinitiationofrollingisthebreakawayangle.Thistestmethodcanbeusedtomeasuretheangleatbreakawayofsmalldiameter(upto100mmoutsidediameter)rollingelementbearings.Thebearingsthathavebeentestedinthedevelop-mentofthismethodareconventionalballbearingswithdifferentseparators,seals,anddifferentconditionsoflubrica-tion(none,oil,greases,andsoforth),butthereisnotechnicalreasonwhythistestmethodwouldnotworkwithbearingsofotherdesign,includingplainbearings.Rollingelementbear-ingslikeanyslidingsystemcanhavefrictioncharacteristicsatbreakawaythataredifferentthanrollingcontinuously.Asisthecasewithmostinclinedplanefrictiontests,thetestonlyproducesthefrictioncharacteristicattheonsetofmeasurablerolling,usingtheangle(θ)whenmeasurablerollingcom-mences.Theobjectiveofthistestisanassessmentofbreak-awayrollingfrictioncharacteristicstoassistmachinedesignersintheselectionofrollingelementbearingsforinstrumentpivotsandthelikewherebreakawayfrictionisaconcern.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety...