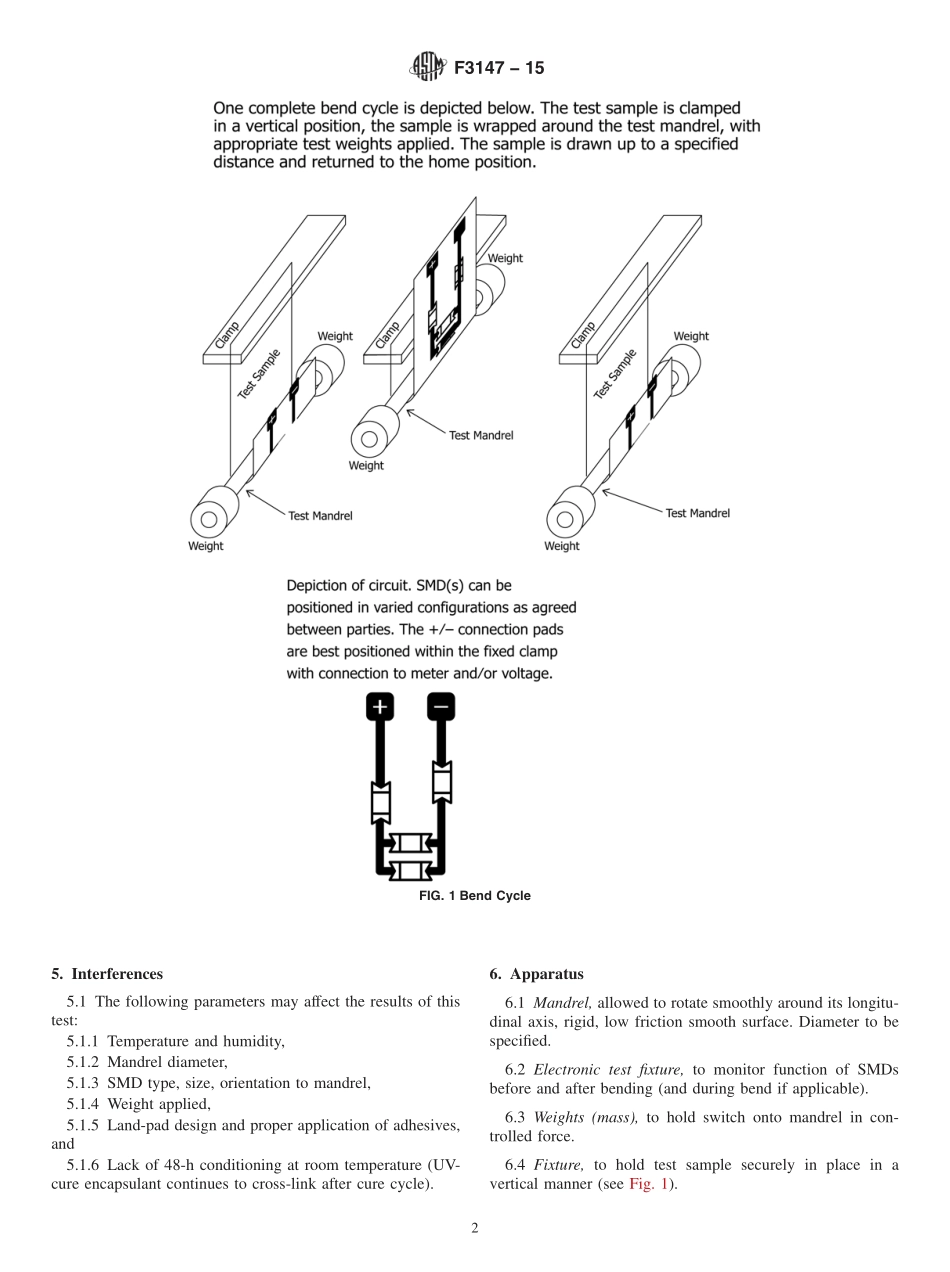

Designation:F3147−15StandardTestMethodforEvaluatingtheReliabilityofSurfaceMountedDevice(SMD)JointsonaFlexibleCircuitbyaRollingMandrelBend1ThisstandardisissuedunderthefixeddesignationF3147;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1ThistestmethodcoversameanstotestacompletedSurfaceMountedDevice(SMD)jointforbondstrengthandinter-layerstresscompatibility1.2AcompletedSMDjointincludes;SMD(LED,resistor,etc),PTFinkland(typicallysilver),conductiveadhesive(typicallysilver),stakingcompound(non-conductive),andencapsulant(non-conductive).2.ReferencedDocuments2.1ASTMStandards:F1996TestMethodforSilverMigrationforMembraneSwitchCircuitryF2750TestMethodforDeterminingtheEffectsofBendingaMembraneSwitchorAssembly3.Terminology3.1bend,v—toforcefromastraightformintoadifferentandespeciallyacurvedone.3.1.1Discussion—Inthiscase,no“hard”orangledcreaseorfoldistooccur.Thesubstratewillonlybeformedintoaradius.3.2bendcycle,n—abendofasamplearoundaspecifiedmandrelwhichis“rolled”inonedirection,followedbyrollingintheoppositedirection,returningthesampletoitsoriginalposition(seeFig.1).3.3conductiveadhesive,n—amaterialusedforelectricalormechanicalbonding,orboth,oftheSMDtothesubstrateandland-pad.3.4encapsulant,n—anon-conductiveadhesivethatisap-pliedoveroraround,orboth,theSMDforaddedbondstrengthandpreventionofsilvermigration(F1996).3.5land-pad,n—theprintedcircuitpatternatthelocationthatinterfaceswithconductiveadhesive,inthiscaseconduc-tivelinkcircuitry(commonlysilver)thatwillmakeelectricalcontacttotheSMDviaconductiveadhesive.3.6mandrel,n—acylindricallyshapedmetalrod,suchasabrazingordrillrod.3.7SMD,n—abbreviationforsurfacemountdevice(thatis,lightemittingdiode(LED),resistor,capacitor,etc.).3.8SMDjoint,n—thecombinedinterfaceofsilverland-pad,conductiveadhesive,stakingcompound...