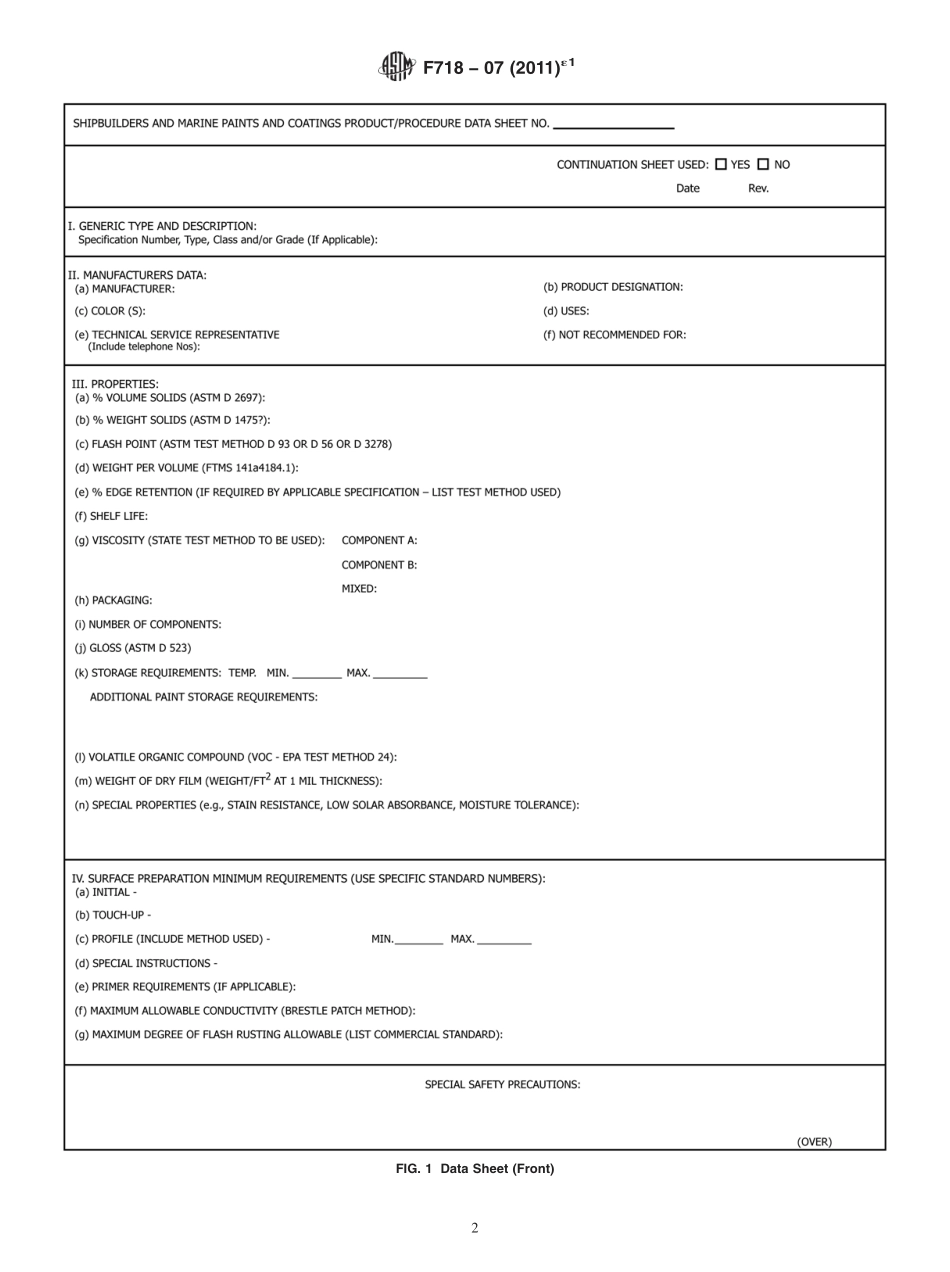

Designation:F718−07(Reapproved2011)´1AnAmericanNationalStandardStandardSpecificationforShipbuildersandMarinePaintsandCoatingsProduct/ProcedureDataSheet1ThisstandardisissuedunderthefixeddesignationF718;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.ε1NOTE—ReapprovedwitheditorialcorrectionsinNovember2011.1.Scope1.1TheShipbuildersandMarinePaintsandCoatingsProduct/ProcedureDataSheet2providesononesheetneededinformationconcerningthecharacteristicsofaspecificpaintorcoatingtoincludegenericdescription,physicalproperties,surfacepreparationrequirements,applicationrequirements,andsafety.Thefrontsideofthesheetcontainsfourmajor,numberedparagraphsandahighlightedsectionforSpecialSafetyPrecautions.Theseparagraphsareasfollows:I.GenericTypeandDescriptionII.ManufacturersDataIII.PropertiesIV.SurfacePreparationMinimumRequirementsThebacksideofthepagecontainsthefollowingparagraphs:V.MixingProcedureVI.Application.1.2Thecompleteddatasheetscanbeusedbytechnicalpersonneltohelpevaluatethetechnicalacceptabilityofaproposedmaterial,byproductionpersonneltoevaluatepro-ductioncompatibilityofproposedmaterialsandtoprovideapplicationinstructionsforselectedpaintsandcoatingsmaterials,andbyqualitycontrolpersonneltoverifyattributesofmaterials.2.ReferencedDocuments2.1ASTMStandards:3D56TestMethodforFlashPointbyTagClosedCupTesterD93TestMethodsforFlashPointbyPensky-MartensClosedCupTesterD523TestMethodforSpecularGlossD1475TestMethodForDensityofLiquidCoatings,Inks,andRelatedProductsD1640TestMethodsforDrying,Curing,orFilmFormationofOrganicCoatingsatRoomTemperatureD1650TestMethodsforSamplingandTestingShellacVarnish(Withdrawn1997)4D2697TestMethodforVolumeNonvolatileMatterinClearorPigmentedCoatingsD3278TestMethodsforFlashPointofLiquid...