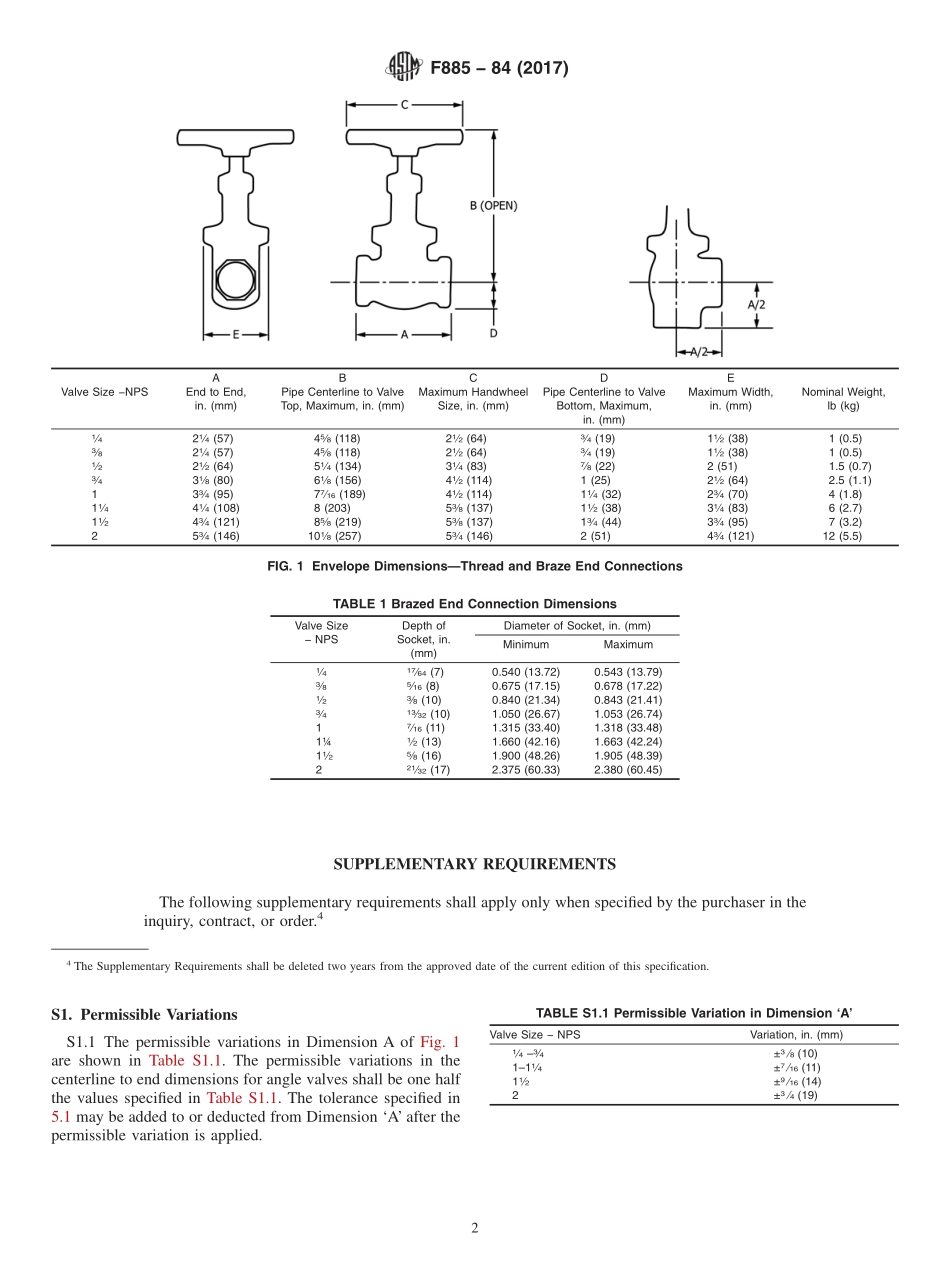

Designation:F885−84(Reapproved2017)AnAmericanNationalStandardStandardSpecificationforEnvelopeDimensionsforBronzeGlobeValvesNPS1⁄4to21ThisstandardisissuedunderthefixeddesignationF885;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationprovidesstandarddimensionsforsmallbronzeglobevalves(NPS1⁄4to2)installedinshipboardpipingsystems.1.2ThisspecificationcoversvalvesofanominalpipesizefromNPS1⁄4to2withthreadedandbrazedendconnections.ThevalvesareinaccordancewithMSS-SP80,Class200.1.3Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ANSIStandard:2B2.1PipeThreads(ExceptDryseal)2.2Manufacturer’sStandardizationSocietyoftheValveandFittingsIndustryStandard:3SP80BronzeGate,Globe,AngleandCheckValves3.MaterialsandManufacture3.1ThreadedendconnectionsshallbeinaccordancewithANSIB2.1.BrazedendconnectionsshallbeinaccordancewithTable1.4.Dimensions4.1Valvedimensionsforboththreaded-andbrazed-typeendconnectionsareprovidedinFig.1.5.Tolerances5.1Aplusorminustoleranceof1⁄32in.(0.8mm)shallbeallowedonalldimensionsthatdonothaveamaximumorminimumspecified.6.Keywords6.1brazedconnection;bronzeglobevalve;envelopedimen-sion;globevalve;marinetechnology;ship1ThisspecificationisunderthejurisdictionofASTMCommitteeF25onShipsandMarineTechnologyandisthedirectresponsibilityofSubcommitteeF25.11onMachineryandPipingSystems.CurrenteditionapprovedMay1,2017.PublishedJune2017.Originallyapprovedin1984.Lastpreviouseditionapprovedin2011asF885–84(2011).DOI:10.1520/F0885-84R17.2AvailablefromAmericanNationalStandardsInstitute(ANSI),25W.4...