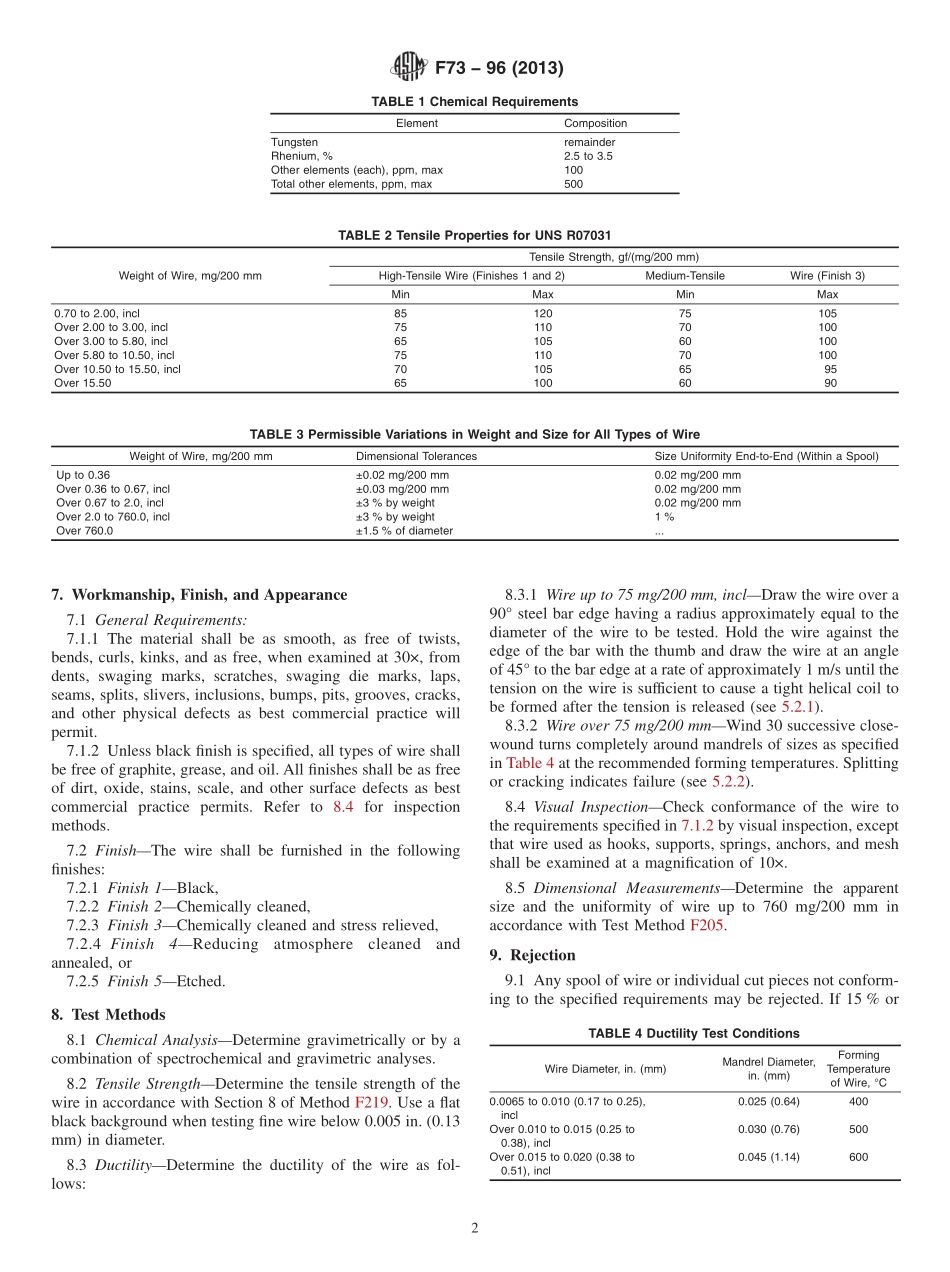

Designation:F73−96(Reapproved2013)StandardSpecificationforTungsten-RheniumAlloyWireforElectronDevicesandLamps1ThisstandardisissuedunderthefixeddesignationF73;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoverstungsten-rheniumalloywiresuitableforuseinelectrondevicesandlamps.ThematerialisknownasUNSR07031.1.2Thetermwireasusedinthisspecificationappliestoallmaterial0.020in.(0.51mm)orlessindiameterthatisspooledorcoiled.1.3Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2F205TestMethodforMeasuringDiameterofFineWirebyWeighingF219TestMethodsofTestingFineRoundandFlatWireforElectronDevicesandLamps3.OrderingInformation3.1Ordersforwirefurnishedtothisspecificationshallincludethefollowinginformation:3.1.1Lengthinmetres,3.1.2Nameofmaterial,3.1.3Straightness(see6.2),3.1.4Finish(see7.2),3.1.5Weightorsize(see6.1)andtolerance,and3.1.6SpecificationnumberandUNSnumber.NOTE1—Atypicalorderingdescriptionforstraightchemicallycleanedwireisasfollows:xxxxmetrestungsten-rheniumalloywire,straightened,Finish2;280.8mg/200mm(63%),perASTMF73–XX(UNSR07031).4.ChemicalComposition4.1ThiswireshallconformtotherequirementsastochemicalcompositionprescribedinTable1.5.PhysicalProperties5.1TensileStrength—Thetensilestrengthofa10-in.(250-mm)gagelengthofwireingrams-forcepermilligramper200mmshallbewithinthelimitsprescribedinTable2,whentestedinaccordancewith8.2.5.2Gener...